Manual FLOW 38 Page 8 (total 54) COMAC CAL s.r.o.

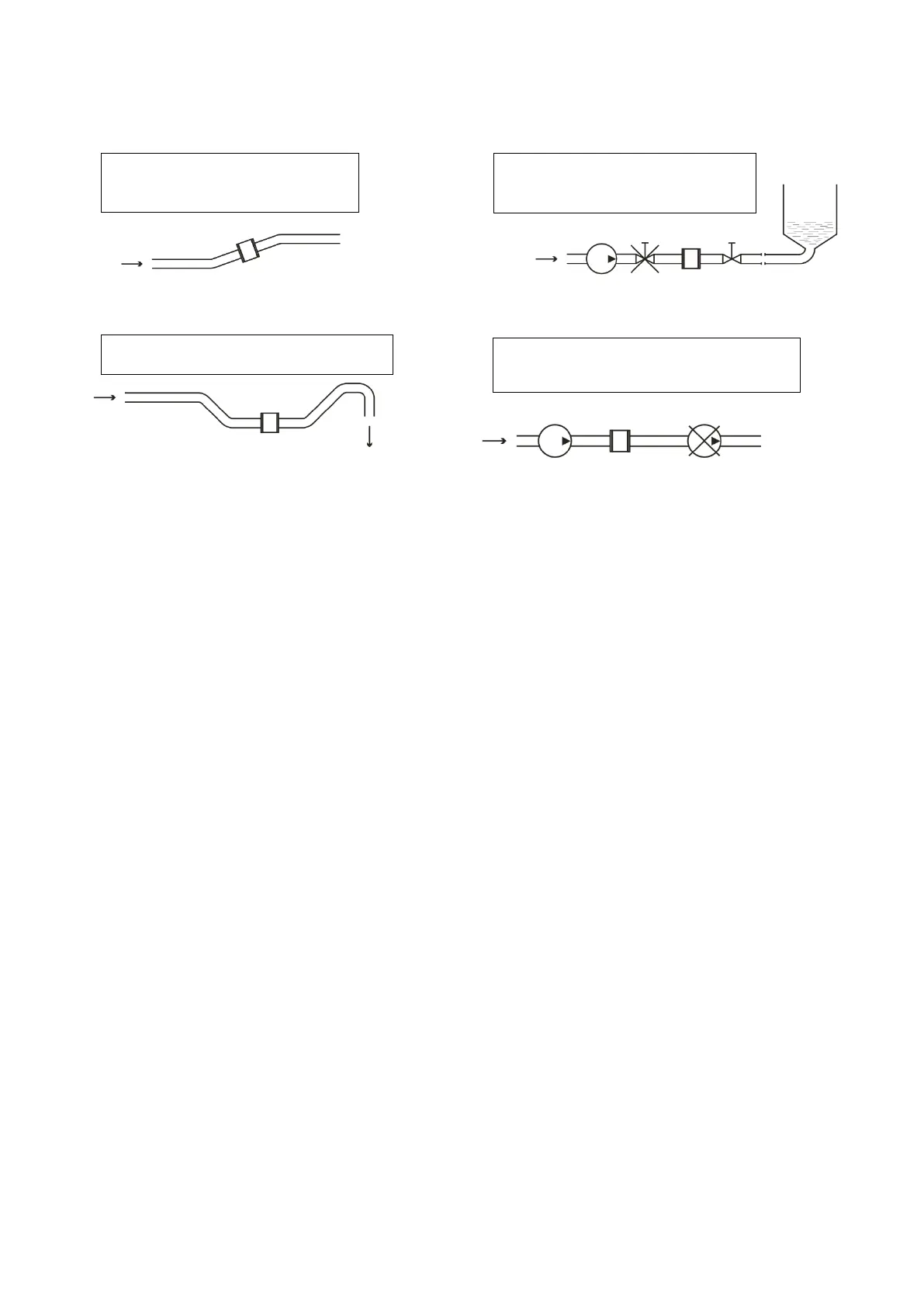

Horizontally laid pipeline Long pipeline

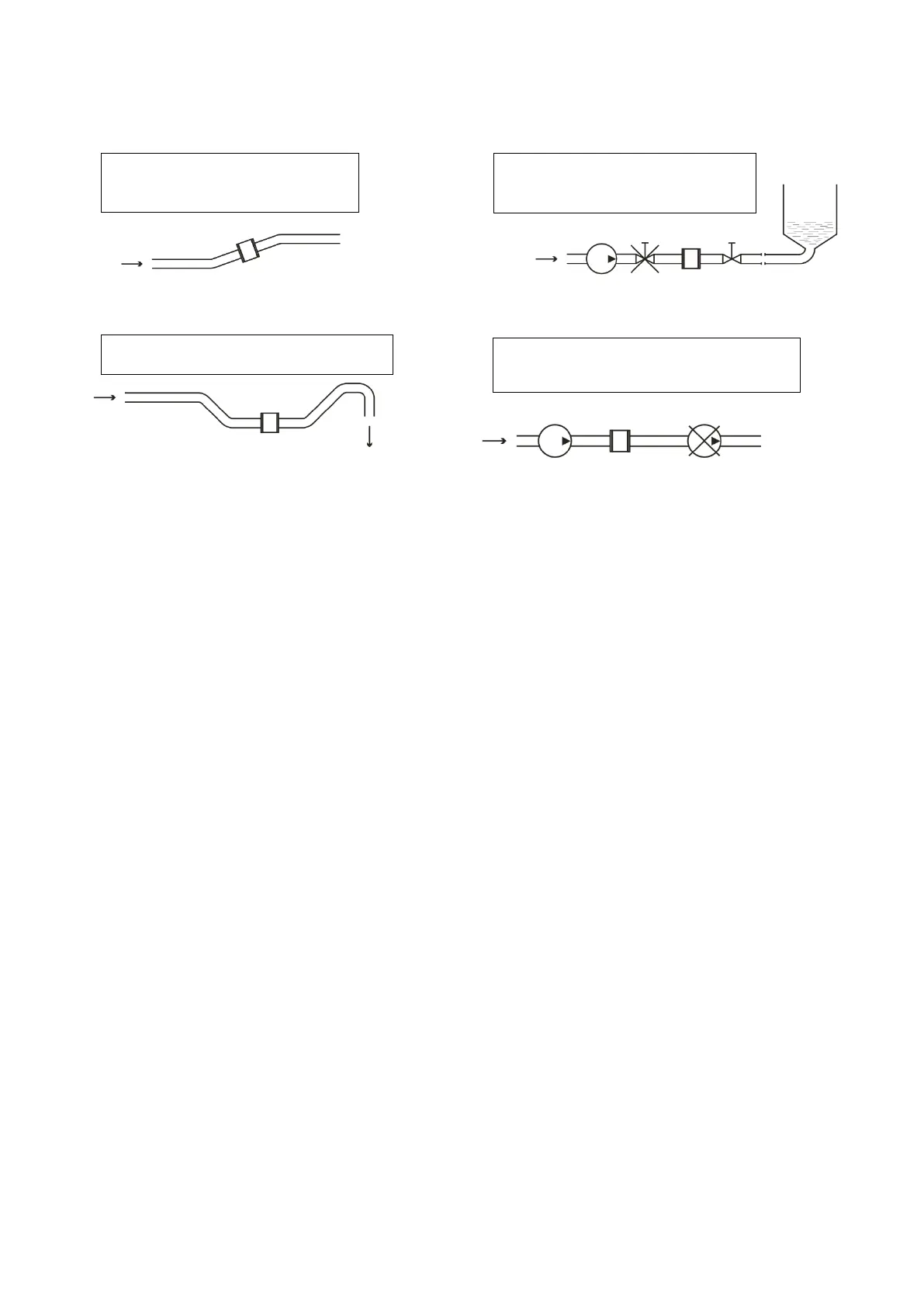

Free inlet or outlet Pumps

The flow of liquid flow in the flow sensor should be steady and free of whirling. For this reason,

straight sections of pipeline with the same ID as that of the flow meter before and after the flow sensor

(with permissible deviation of +5%). Recommended minimum length of straight sections is 5d before

the flow sensor and 3d after the flow sensor where d is the inside diameter of the meter in millimetres.

The same principles apply before and after the flow sensor in case of bi-directional flow measurement.

Recommendations

• In case of whirled up flow, extend the calming sections of pipeline or integrate a flow conditioner.

• When blending a mixture of substances, it is necessary to install the flow meter either before the

point of blending or at a sufficient distance after it (30d min. where d is the inside diameter of

the meter in millimetres), otherwise it will result in instability of indication.

• When plastic pipeline is used or in case of metallic pipes with internal non-conductive layer,

earthing rings are needed.

• Do not install the sensor at the suction side of the pumps; this will eliminate the risk of vacuum

and possible damage to the measuring tube lining.

• Pumps, bends and elbows found closely in succession in various levels should be at a distance

of 20d at least before the flow sensor. In case of a separate elbow or bend, the placement 10d

before the meter is recommended.

• When piston pumps, diaphragm pumps, and flexible tube pumps are used, it is necessary to install

a pulse damper in the system.

• In order to provide the highest accuracy, it is important to ensure permanent flooding for the

sensor (for example, by installation of the sensor in the U-shaped pipeline) even if the sensor is

equipped with empty tube test. This will serve as an additional safety measure for detection of

non-flooded tube.

The responsibility for suitability and adequacy of application of induction flow meters is borne by the

designer or possibly the user himself.

Loading...

Loading...