12

Version 2.2

The compressed air cools to dew-point +3°С by means of heat exchange. The water vapour

present in the compressed air is condensed. The condensate formed is extracted by the

condensate drain valve (9). Hot refrigerant enters the suction line of the compressor (1)

from the evaporator (2) and the cycle repeats itself. In order to stabilize the pressure of the

refrigerant in the condenser (3), a pressure relay (8) is installed, which controls function of

the fan (4). If the pressure in the evaporator (2) drops (insufcient quantity of compressed

air enters the dryer, no-load operation) a hot gas bypass valve is activated and it allows

pressure in the evaporator to drop lower than the dened level.

2.4 Conversion table of performance for different

operating conditions

RDX refrigerated dryers are designed in conformity with ISO 7183 under standard operat-

ing conditions: working pressure 7 bar, ambient temperature +25°C, compressed air inlet

temperature +35°C.

Any deviation from standard conditions requires dryer size adjustments.

Use Correction Factor tables to help determine dryer size.

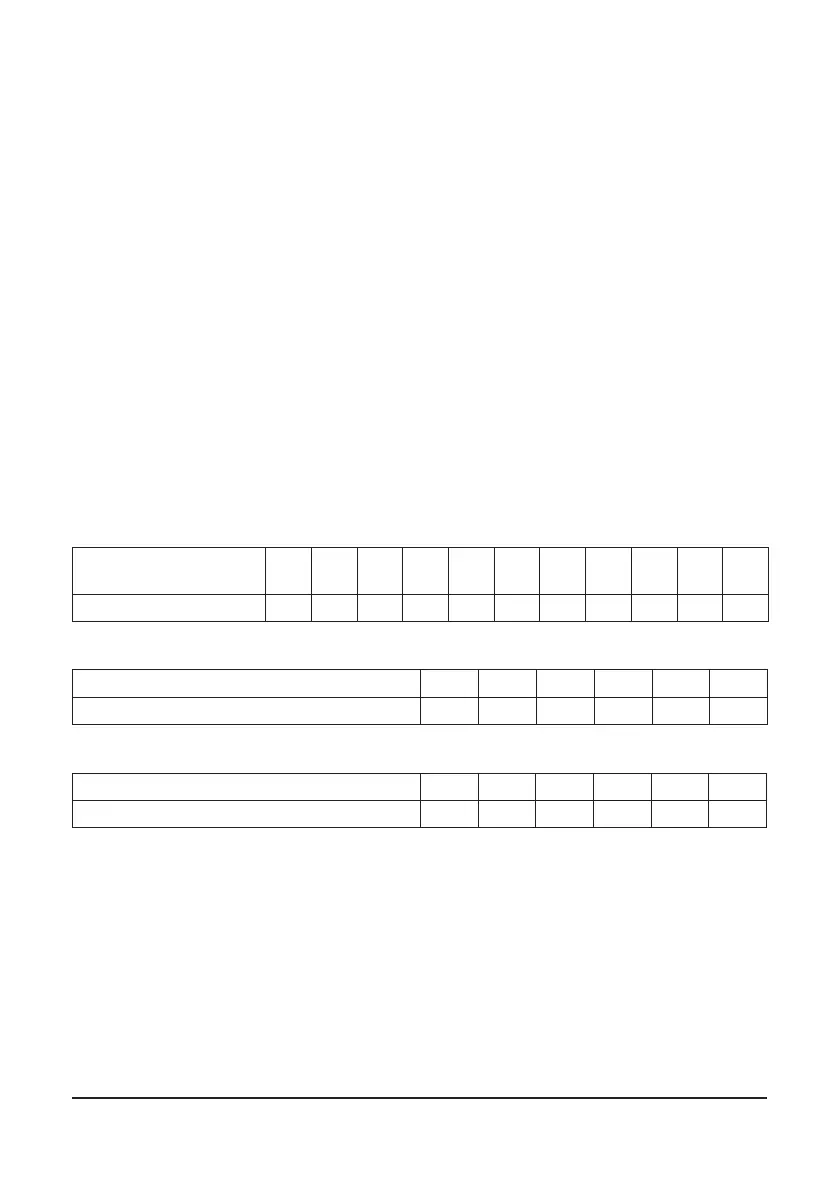

Maximum working pres-

sure, MPa

0 0,1 0,2 0,4 0,6 0,7 0,8 1,0 1,2 1,4 1,6

F1 X X X 1,25 1,06 1,00 0,96 0,90 0,86 0,82 0,8

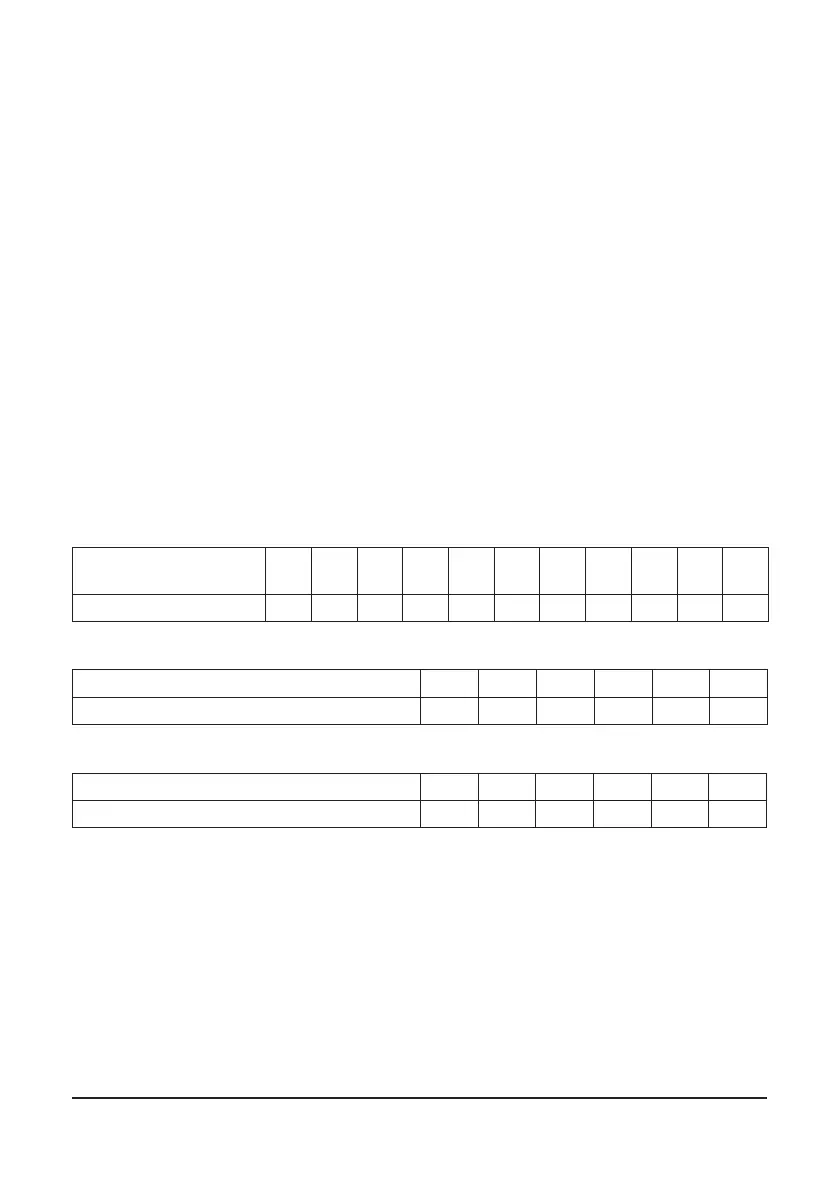

Maximum inlet temperature of compressed air,

0

C +30 +35 +40 +45 +50 +55

F2 0,85 1,00 1,18 1,39 1,67 2,00

Ambient Temperature, °C +20 +25 +30 +35 +40 +45

F3 0,92 1,00 1,07 1,14 1,22 1,3

Capacity = Capacity at standard operating conditions x F1 x F2 x F3

Loading...

Loading...