Programming and Testing the

Installed Kit

Note: Follow the testing and programming procedures in

S280-77-1 Kyle Form 4C Microprocessor-Based

Recloser Control Installation and Operation Instructions

before placing the control back in service.

1. Reconnect the battery connector.

2. Energize the control with AC power.

3. Program the control. Refer to S280-77-4 Kyle

®

Form

4C Microprocessor-Based Recloser Control

Programming Guide for further information.

4. Test the control with the Kyle

®

Type MET Electronic

Control Tester (or equivalent) to verify proper pro-

gramming and operation

5. After all programming and testing has been success-

fully completed, the control may be reinstalled and

placed into service. Refer to S280-77-1 Kyle Form 4C

Microprocessor-Based Recloser Control Installation

and Operation Instructions.

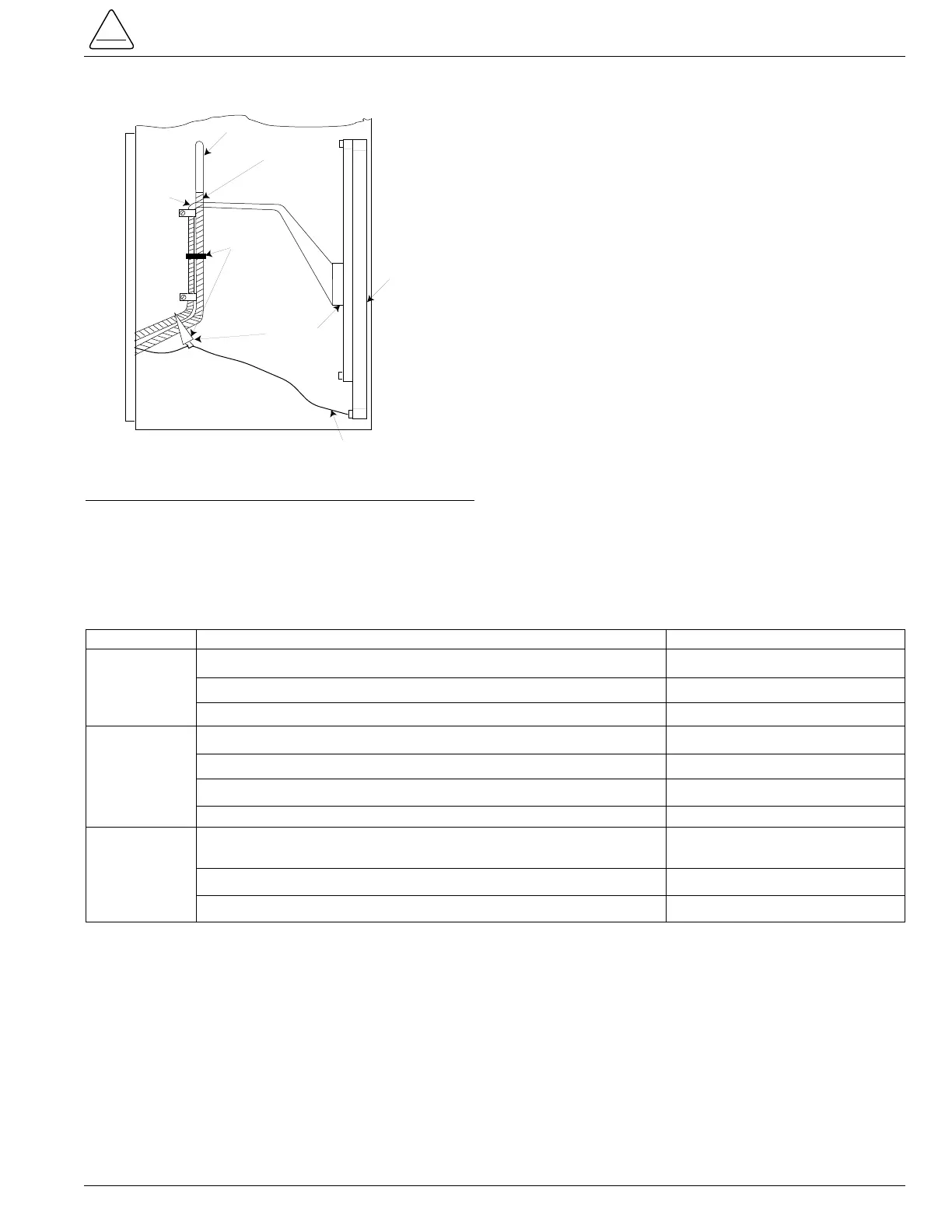

Troubleshooting

If the front panel fails to operate properly, review the trou-

bleshooting information in Table 2 prior to contacting your

Cooper Power Systems representative.

S280-77-13

7

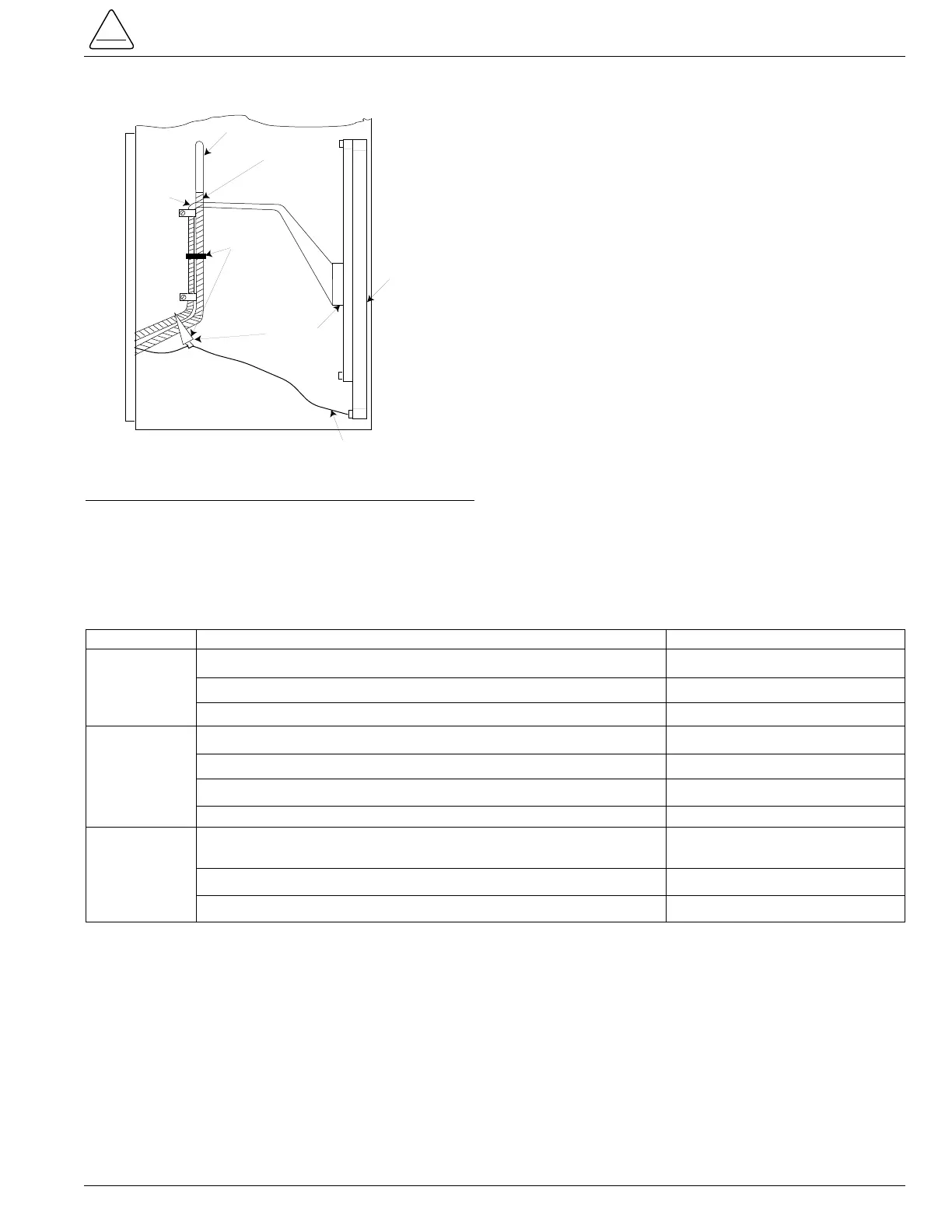

Figure 5.

Securing with Ty-wraps.

Problem Possible Causes Remedy

No power to control. Neon lamp on power supply should be “ON”. Connect power.

Cable to power supply P12 not connected. Connect plug.

Cables incorrectly attached or damaged. Inspect all cables.

Battery left connected without 120 Vac supplied to control. Contact Cooper Power Systems.

Battery drained. Contact Cooper Power Systems.

Battery disconnected. Connect battery.

Cables incorrectly attached or damaged. Inspect all cables.

Incorrect program parameters. Verify unit was programmed

correctly. Refer to S280-77-4*.

Cables incorrectly attached or damaged. Inspect all cables.

Cable socket pins bent. Inspect / straighten pins.

Display Will

Not Turn

On

Malfunction

Display ON

and Check

Battery

Display ON

Unit Failed

KMET

Testing

* S280-77-4 Kyle

®

Form 4C Microprocessor-Based Recloser Control Programming Guide

TABLE 2

Troubleshooting Information

Loading...

Loading...