Coopra Advanced Heating Technologies Installation manual E40C

12

1.7. Operation

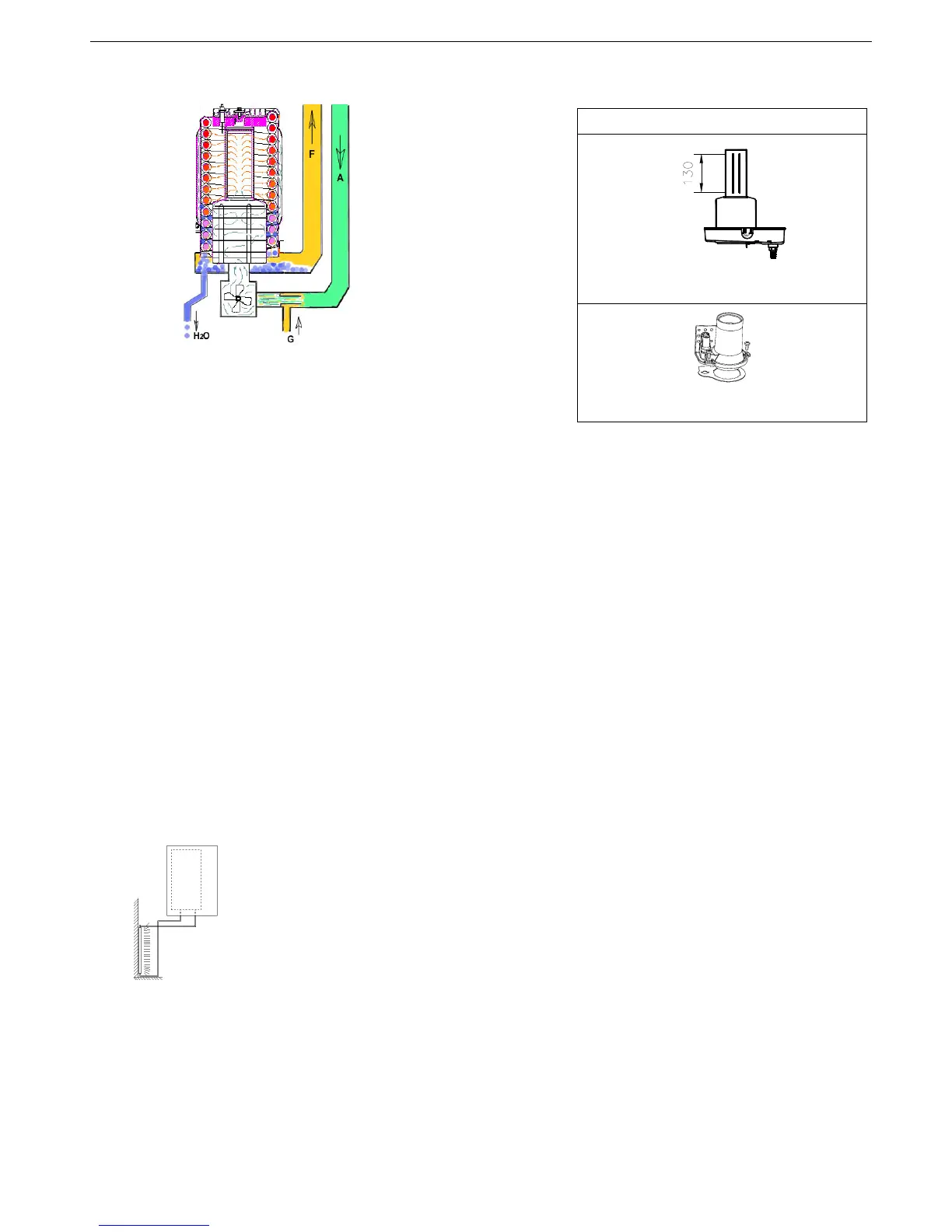

A fan sucks the air required for the combustion through

the air feed canal (A). Because the combustion air in the

venturi sucks an under pressure, the correct amount of

gas (G) is automatically added to the combustion air.

The flammable gas/air mixture thus obtained is fed to the

burner, via a mixing chamber, to be ignited at the surface

of the burner by a ceramic glow plug. The hot

combustion gases are efficiently fed through the heat

exchanger, where they give their heat to the water. The

flue gases are fed outside, through the flue tube (F), into

a flue tube exhaust canal.

The condensation water (H

2

O) thus obtained is

discharged into the sewer.

1.8. Boiler types

The Coopra boiler is a heating unit with compact

dimensions and a very high efficiency, with versions for

domestic use for heating or in combination with domestic

hot water.

The type plate, which specifies the type of gas etc. to be

used, for which the boiler is set, is on the left side of the

boiler.

The boiler is fixed to the wall with the aid of a separately

delivered assembly bracket or rear cabinet.

1.8.1. Coopra 40C

High efficiency boiler for heating only

1.8.2. Technical characteristic

Boiler type 40

burner

Burner ports 130 mm

Sset02, Burner type30/40

venturi

Diameter inlet 25 mm

Sset51, Venturi type 40

Loading...

Loading...