Coopra Advanced Heating Technologies Installation manual E40C

27

7.6.4. Check function of gas control

- open the outlet pressure nipple of the gas valve

- connect the pressure gauge to the outlet pressure nipple

- measure the outlet pressure (zero)

- start heat demand (chimney sweeper function)

- first, the fan will pre-purge at 1800 rpm

- next, the fan runs at the ignition speed of 2900 rpm.

- now, the pressure gauge will indicate an under pressure

of approximately 3 mbar

- the same moment the gas valve opens, the zero

governor makes zero gas pressure.

- if not, then the gas control is not functioning.

7.6.5. Check glow plug (no ignition)

BE CAREFUL !!!

230 VAC

The 230 volt glow plug is in order if the measured

resistance at room temperature is about 1.0 - 1.4 kOhm.

Replacing the glow plug

The glow plug is a resistance through which current is fed.

As a result of the high temperature of the glow plug, the

burner can be ignited. This makes the glow plug a part

that wears. The average life of the glow plug is estimated

at 8 years, depending on the number of starts and on the

variation of the mains voltage.

• remove plug from glow plug (230 V high voltage)

• remove glow plug from cover of heating unit

• replace glow plug

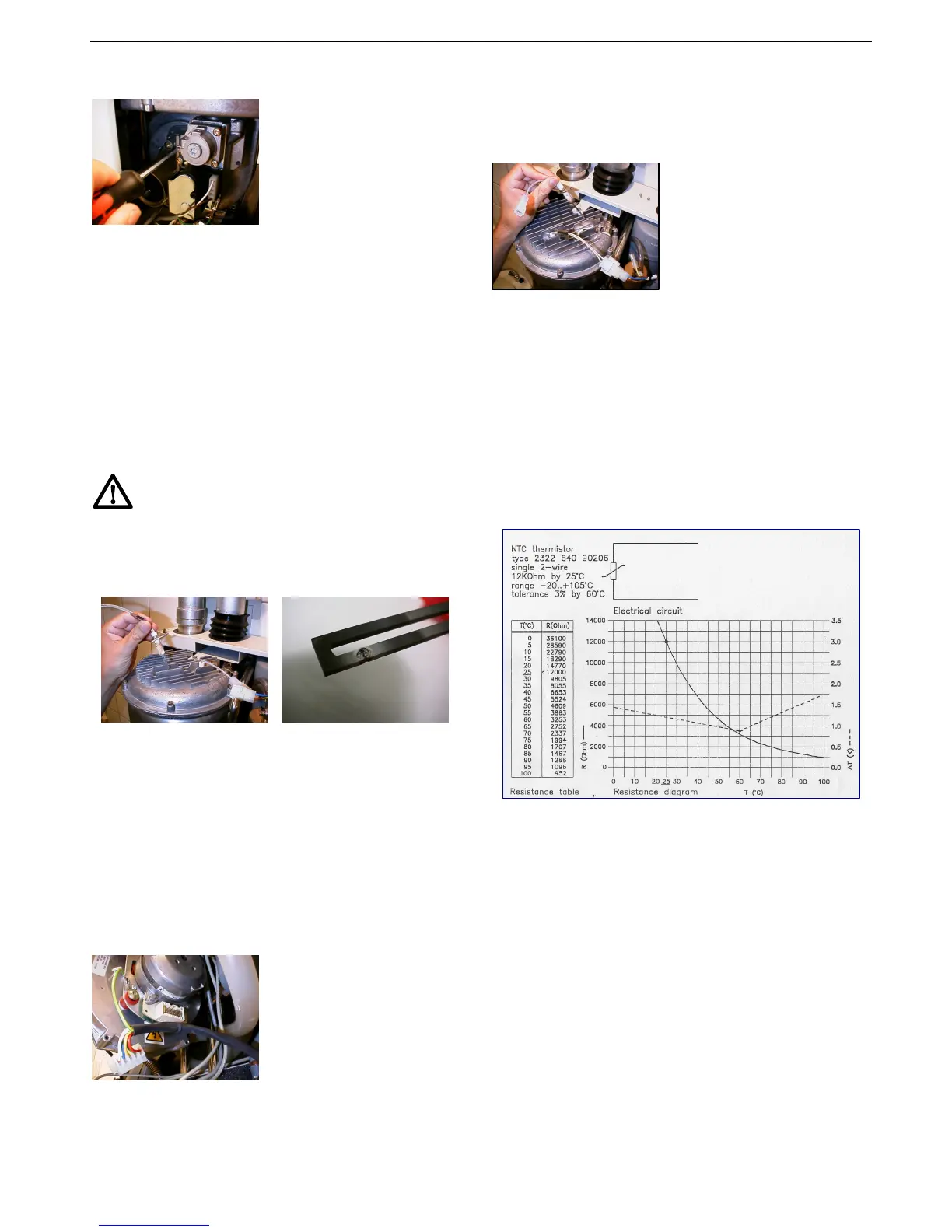

7.6.6. Check the fan impedance

Check the resistance of the

coil, the two outermost

contacts on the fan motor.

The value that the multimeter

shows must be between 115

and 120 Ohms at room

temperature.

7.6.7. Gas/air mixture is not correctly adjusted

See the chapter concerning the adjustment full load and

low load.

7.6.8. Inspection ionisation probe/cleaning

Unplug the plug of the

ionisation probe (low voltage).

Remove the two screws from the ionisation clamp.

Remove the ionisation probe from the lid of the heating

unit.

Check the ionisation probe.

The ionisation probe must be straight and clean (a slight

deposit is normal).

Clean or replace the ionisation probe.

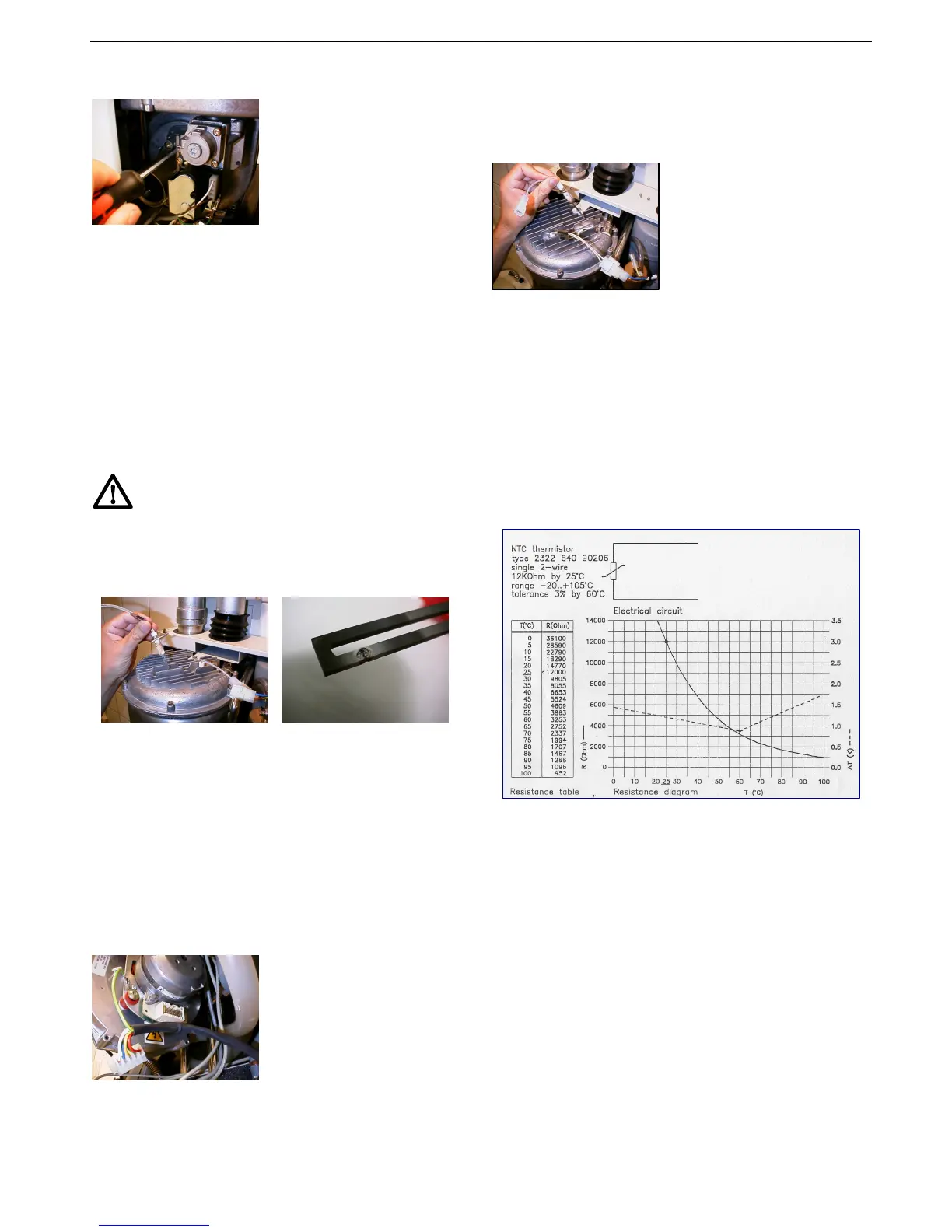

7.6.9. Temperature sensors

The temperature sensors are NTC thermistors of 12kOhm

(@ ambient of 25‘C).

Loading...

Loading...