Coopra Advanced Heating Technologies Installation manual E40C

5

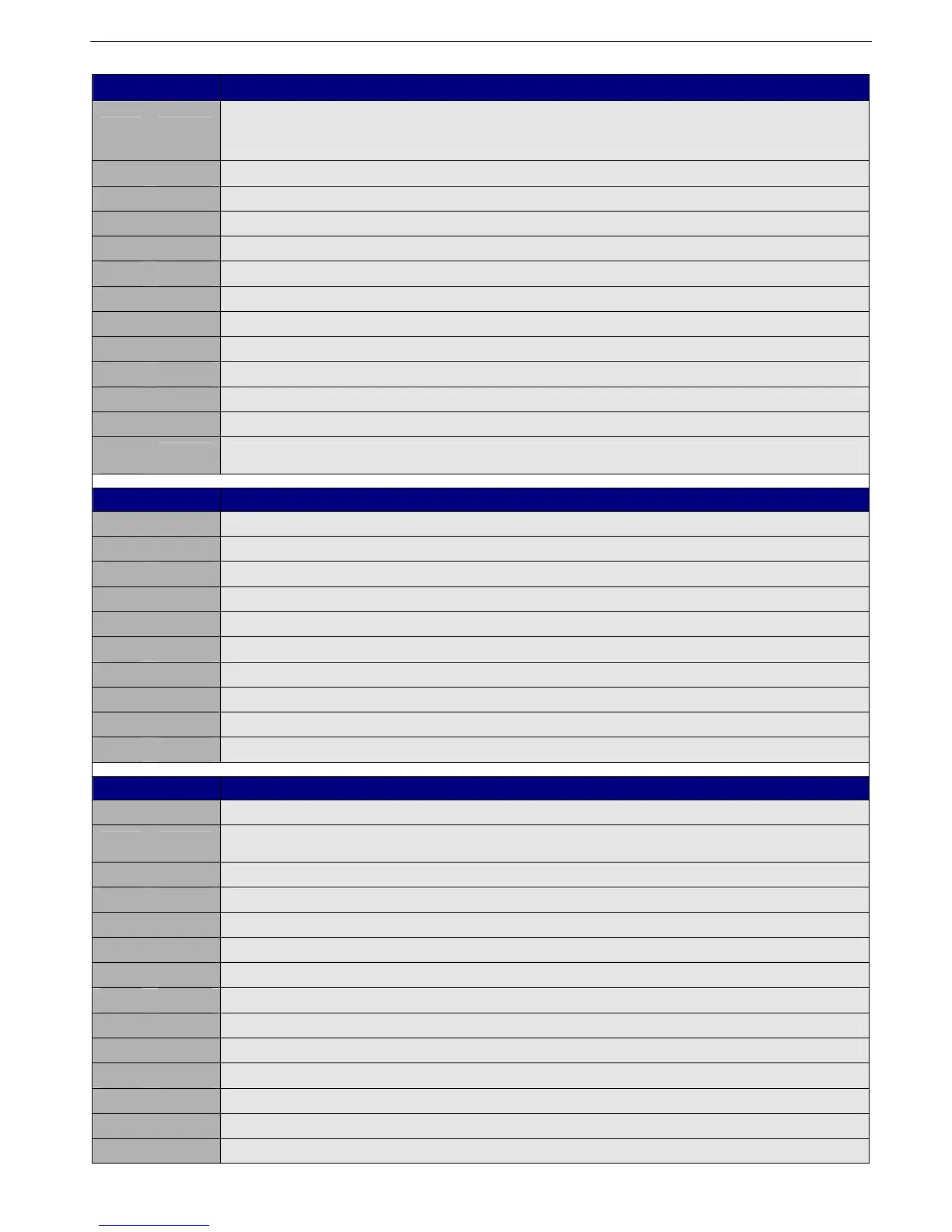

Status Reading

1.3.1. Normal state (continuous code)

P

With initialisation and after restoration of supply power de-aeration programme runs for 2 minutes.

The boiler pump and 3-way valve (if applicable) switch several times, with the purpose to move

eventual air out of the boiler; burner off

0

Stand-by (no heat demand)

C

Heating heat demand, temperature above setpoint, burner off

C.

Heating heat demand, temperature below setpoint, burner on

J

Heating heat demand, 3 minutes anti-cycling time, burner off

c

Pump after run heating mode, burner off

d

DHW heat demand, temperature return sensor of Combi-boiler above setpoint, burner off

d.

DHW heat demand, temperature return sensor of Combi-boiler below setpoint, burner on

b

HWS heat demand, temperature external cylinder above setpoint, burner off

b.

HWS heat demand, temperature external cylinder below setpoint, burner on

o

Frost protection 8°C; burner off, pump on

o.

Frost protection 3°C; burner on, pump on

C

flashing

Chimney sweeper function (ionisation current on the right hand segments)

Status Reading

1.3.2. Blocking state (continuous code)

2

Return sensor temperature 5°C above flow sensor temperature, pump on, burner off

6

Combi boiler internal tank sensor not connected or open (parameter H=01)

6.

Combi boiler internal tank sensor shortcut fault (parameter H=01)

9

Flow or return sensor temperature > 95°C

A

Flue gas sensor temperature > 100°C

b/r

Hot water on right unit of TWIN boiler

E

No SLAVE connected / PCB is set as MASTER, (parameter A=0)

SLA/01

No MASTER connected / PCB is set as SLAVE, (parameter A=1)

P

Water pressure low or high, display shows ‘P’+ pressure

t

Outdoor sensor summer switch on, burner off, (parameter O/t)

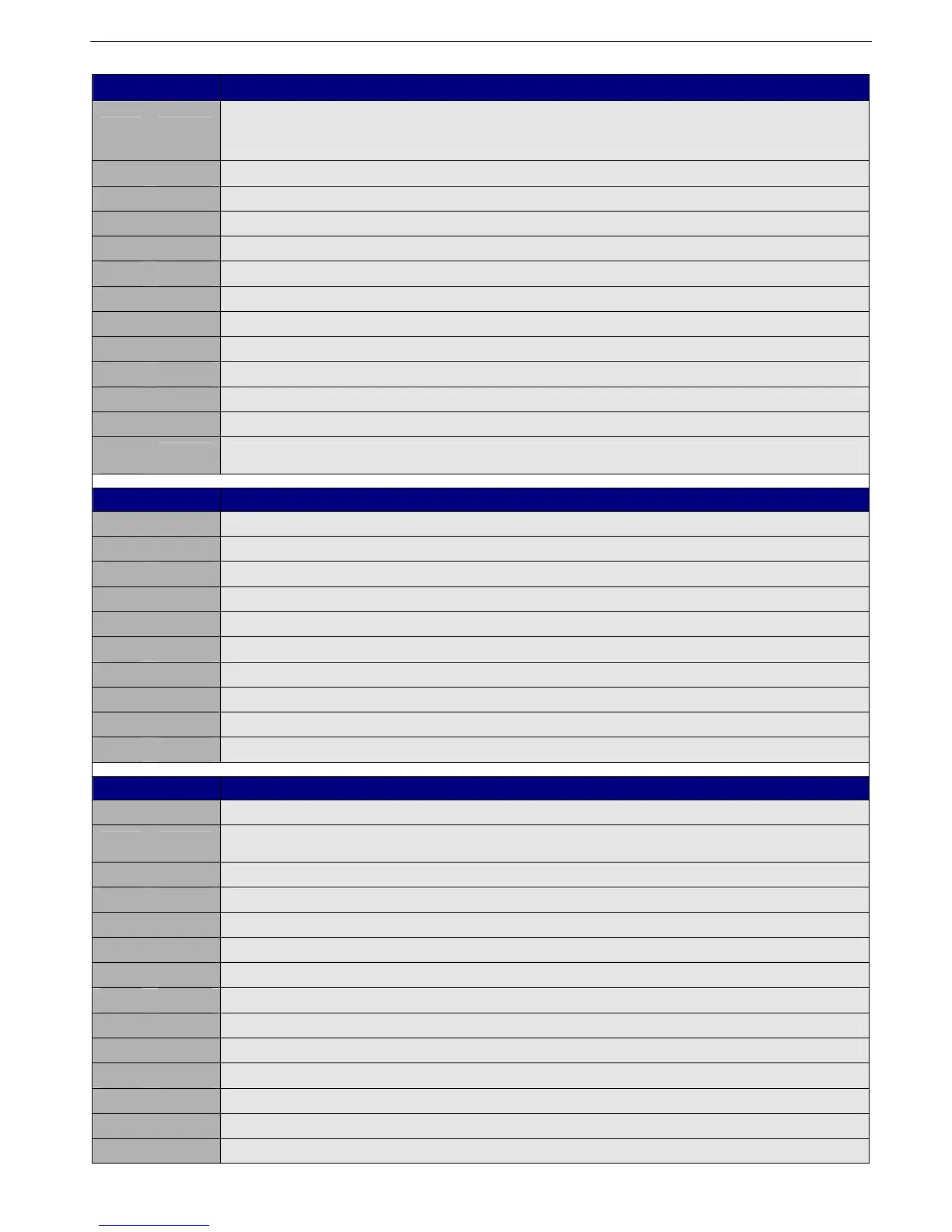

Status Reading

1.3.3. Lock-out state (flashing code)

1

Max delta temperature, differential temperature between flow and return sensor limits 50°C

1

Boiler does not pass temperature test. After burner start the flow sensor must rise 3°C more in

temperature than return sensor within 20 seconds (after 3 start attempts follows lock-out)

2

Flame signal lost 3 times during operation

5

Fan speed error (fan speed deviates > 30% from the speed setpoint)

8

Flame signal detected with closed gas valve

9

Eeprom programmed (to reset press the Set/Reset button)

A

Flue gas temperature > 100°C for more then 3 times within 30 minutes

E

Internal regulation fault / A/D conversion fault (depending type of error display shows ‘E’ or “EEE”)

E t1

Flow sensor open or shortcut fault

E t2

Return sensor open or shortcut fault

E t3

Flue gas sensor open or shortcut fault

F

Too many (4 times) consecutive start attempts

H

Flow or return sensor temperature > 105°C

O

Safety limiter contact is open (no limiter on this boiler, contacts bridged)

Loading...

Loading...