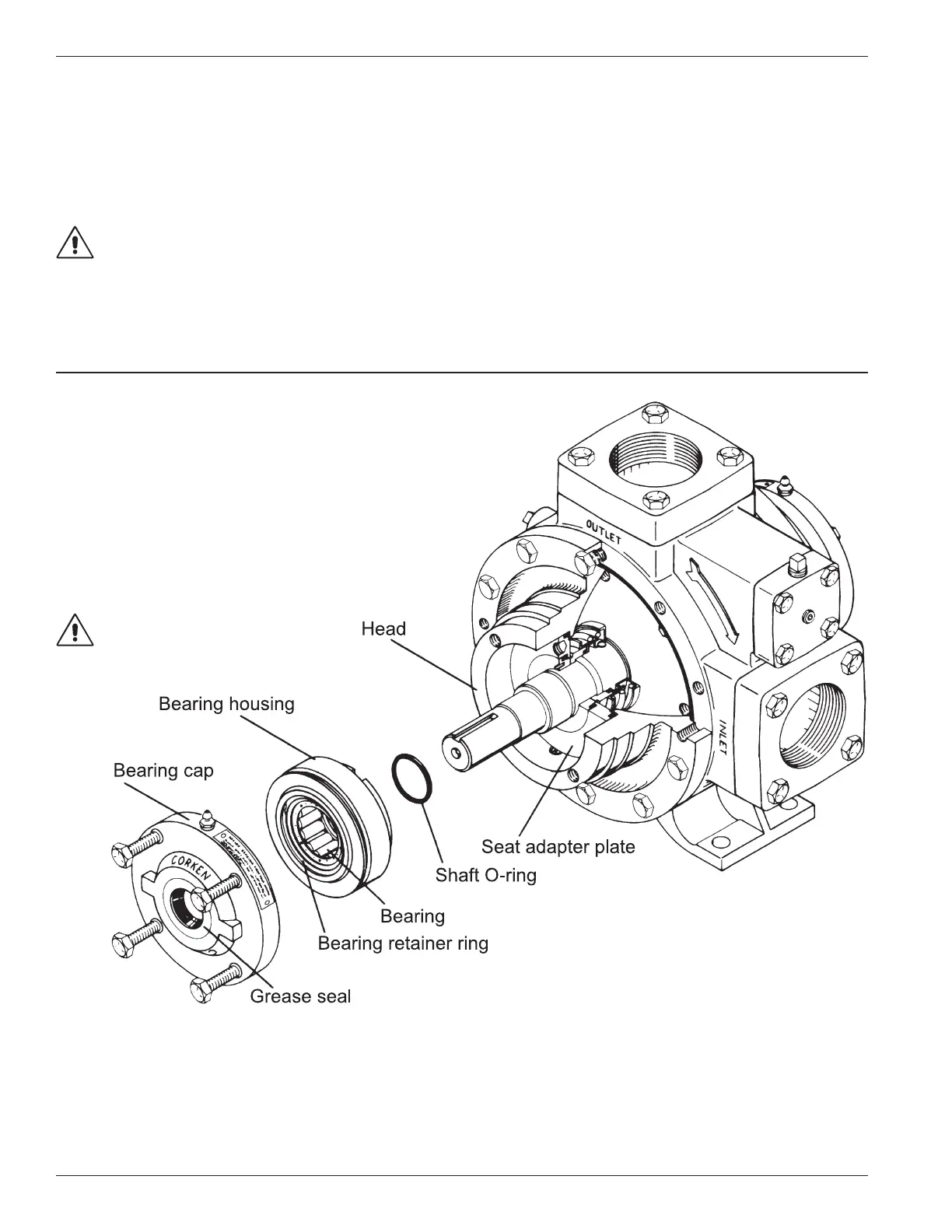

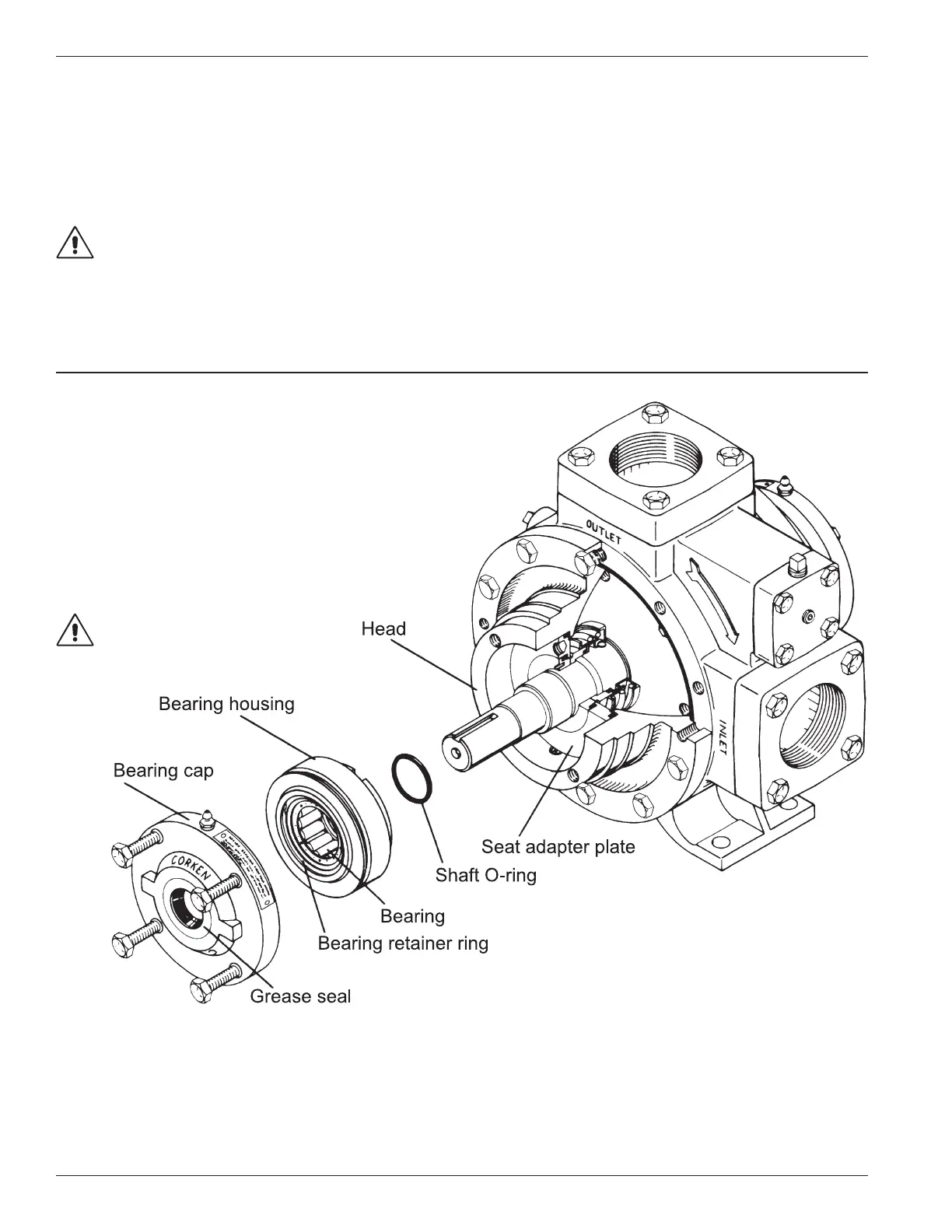

Chapter 4—Seal Replacement

Instructions

For all models 521 and 1021.

Simple as A, B, C... but watch alignments A, B and C or

your new seal will leak!

Caution: Bleed all pressure from the pump and

piping before starting to install your seal assembly.

Cleanliness

Even the smallest amount of dirt on your new seal

can cause early failure. Keep all parts, tools and your

hands clean while installing the seal. Never touch the

smooth lapped faces of the carbon rotor or seal seat.

With LP-Gas, anhydrous ammonia, and similar liquids,

the fluid is 5 to 10 times thinner than water so the

smooth/lapped surfaces of the new seal need to be as

clean as possible.

Workmanship

This pump is a precision piece of equipment with very

close clearances and should be treated with care. Never

beat on it when inserting or removing parts.

Step 1

Depressurize and open the pump.

Remove the bearing cap and bearing housing. Should

the bearing housing be rusted or frozen in place it may be

necessary to remove the entire pump head. The housing

can then be driven out gently with a block of wood.

Remove the old shaft O-ring and discard it. Never reuse

an old O-ring except in an emergency. If you are also

installing a new bearing or grease seal do so now.

Follow established safety

regulations!

10

Loading...

Loading...