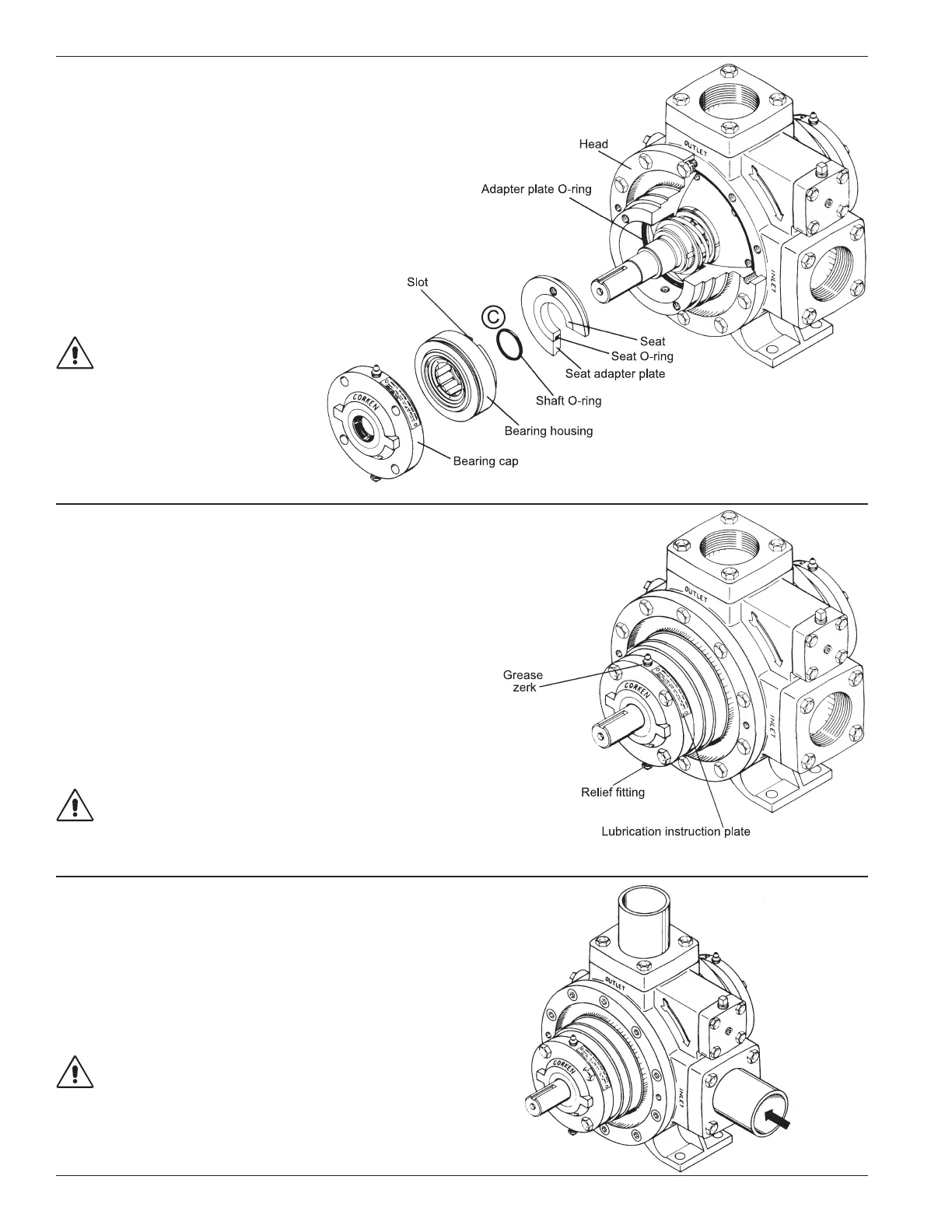

Step 4

Completing the installation.

After applying some oil to the new adapter plate O-ring,

insert it into the pump head. Without touching the lapped

face, insert the new seat and oiled seat O-ring into the

adapter plate. Install the adapter plate in the pump head.

Install the shaft O-ring on the shaft.

C. Slide the bearing housing over the

shaft and install the bearing cap

using a criss-cross method on the

bolts and make sure the pump

shaft turns freely.

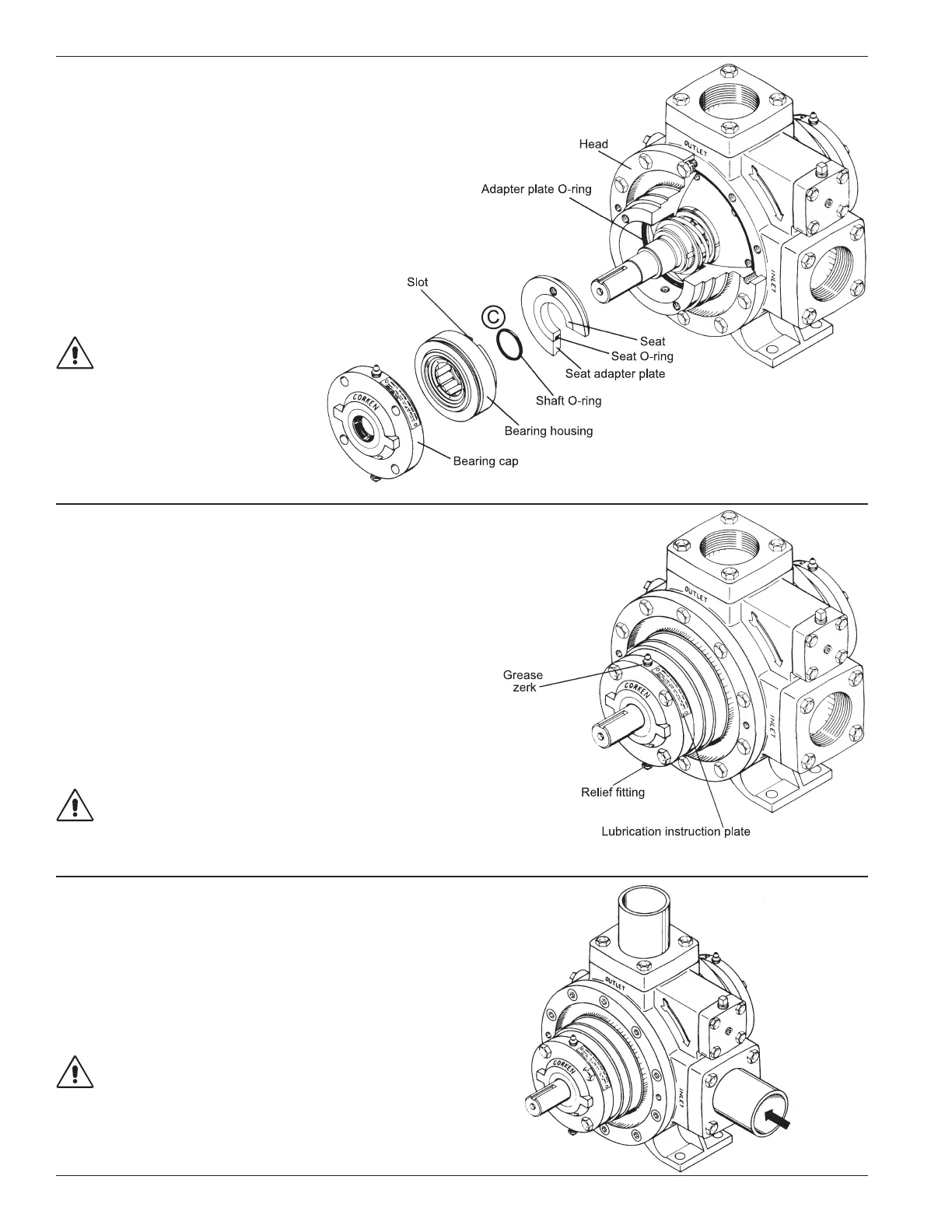

Step 5

Proper lubrication.

For proper lubrication, use MIL-G-10924C ball bearing

grease only. Each pump is equipped with a grease zerk and

relief fitting. Before greasing the bearing, the grease zerk and

relief fitting must be cleaned thoroughly. If any dirt is forced

through the grease zerk, early bearing failure will result.

Overgreasing will damage the pump bearings. To help

prevent overgreasing, use a hand operated grease gun.

Insert the grease slowly and stop as soon as the relief

fitting opens. Excessive grease may drip out of the relief

fitting for several hours after lubrication.

Step 6

Repressurize the system.

For best results slowly pressurize the pump with vapor

before introducing liquid to the pump. When liquid enters

a unpressurized pump-even slowly-it can sometimes

refrigerate enough to keep the O-rings/elastomers from

sealing properly and cause a leak.

Watch alignment C!

Vapor first, then liquid!

Do not overgrease!

NOTE: When lubricating truck pumps, grease the U-joints

and the spline of the drive shaft as well.

12

Loading...

Loading...