1 1

6-2 Standard Operation

All standard operational functions can be control at the Foot Control.

(1) Turn on the Main Power Switch: The Control Unit is ready to perform the Program.

(2) Select the desired program number: Step on the Foot Control PRG (Program) Button and the program

display ascends to the next program number. Pressing the PRG (Program) Button for one second more will

descend the to the next program number.

(3) Verify the details of the program on the display.

(4) Operating the Micromotor : Step on the speed control pedal in the middle of the Foot Control the Micromotor

will start to run. The Coolant Pump will also run (if programmed). Speed increases as the pedal is depressed.

When the Speed Control Pedal is fully depressed the speed reaches the maximum preset value.

(5) Activation of the torque limiter: During use, when the drilling load reaches the preset torque upper limit, the

integrated torque limiter automatically activates to prevent over torque. When the torque limiter activates,

the motor stops after beeping for 1 second. To reactivate the Micromotor, release the speed control pedal

and depress it again.

(6) Stopping the Micromotor: Release the Foot Control Pedal, and the Micromotor will automatically stop.

(7) Reversing the Micromotor rotational direction: To reverse direction of the Micromotor (and bur) simply step

on the Foot Control Forward/Reverse button. A warning beep can be heard when the rotational direction is

in reverse mode.

1 2

7. Cleaning, disinfection, packing and sterilization

7-1 Manual cleaning

• Use the softened water(< 38 °C) and brush to clean the 1# samples.

a. Surface cleaning

• Use the softened water(< 38 °C) and brush to clean the surface of motor and line until visually clean.

b. Crevices and cavities cleaning

• Use the softened water(< 38 °C) and brush to brush E type connector screw, the gap part, the connection gap

of the motor rear part, pay particular attention to all crevices and cavities. Repeat several times until visually

clean. Then Use the water absorbent cloth to remove any remnant of liquid.

7-2 Manual disinfection

Use KaVo Cavicide disinfectant liquid to disinfect the test samples.

7-3 Packing

The quality and use of the sterilisation packaging must comply with applicable standards

and be suitable for the sterilisation procedure!

If potentially infectious liquids and particles can contact the products, it is recommended

to cover and protect these areas with sterile disposable products.

Seal the handpiece tray and motor cable in a sterilisation pouch.

7-4 Sterilization

• Autoclave sterilization is recommended.

holding time15 minutes at 121 °C.

• Implant Handpiece

• Micromotor with Motor Cord (Including the Motor Housing)

• Handpiece Stand

• Internal Irrigation Nozzle

• Tube Holder

• Nozzle Holder

• Autoclave Plug

• Calibration Bur

Note:

▶

▶

• Autoclave sterilization is required for the first time use and after each patient as noted below.

• Autoclave sterilizatio

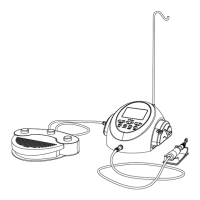

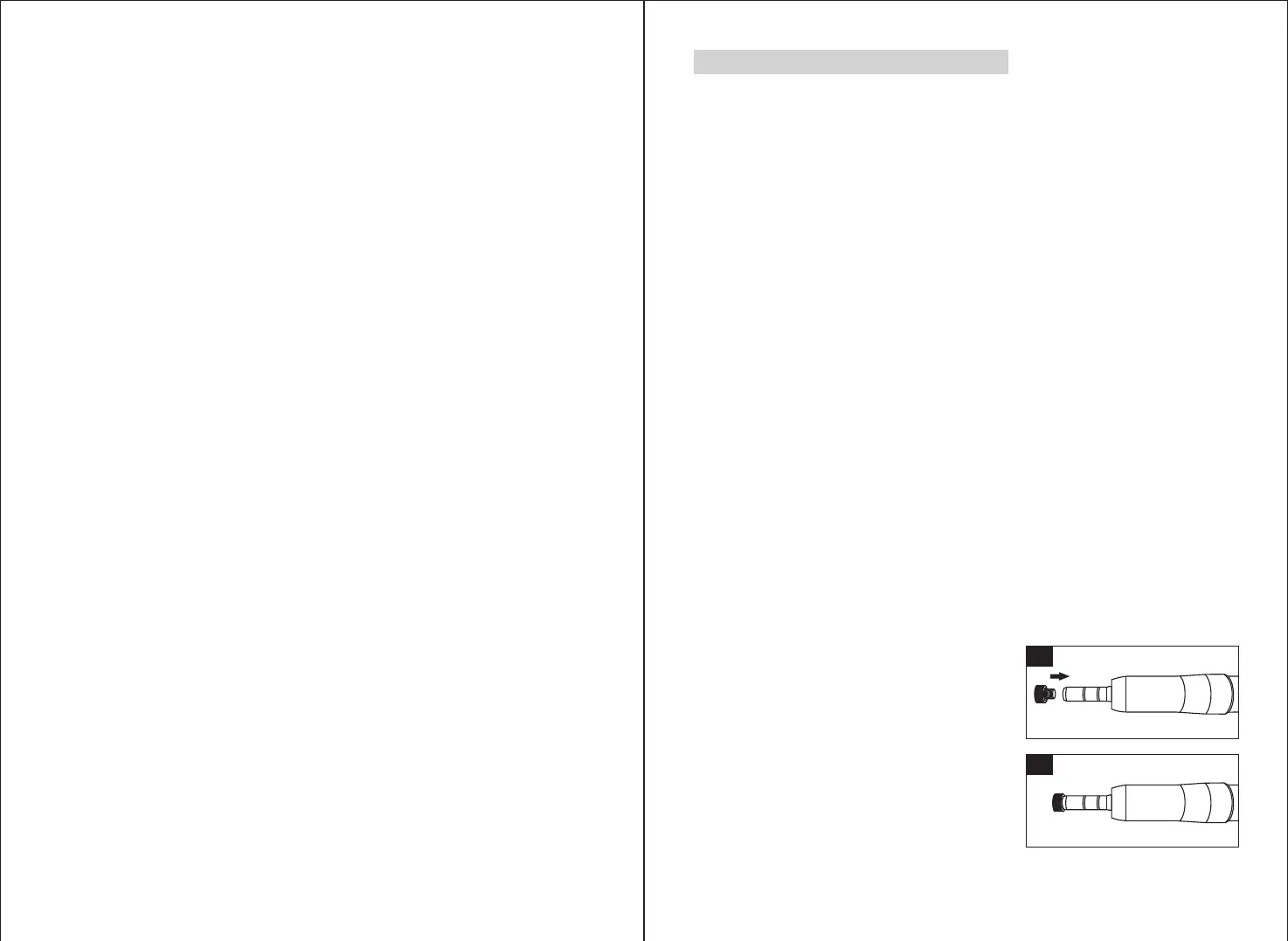

• Attach the Autoclave Plug to the Micromotor.(Fig. 13&14)

• Place those in autoclave pouch (not included in the package) and seal it.

The following items can be autoclaved.

图1 4

图1 3

Loading...

Loading...