1 3

14

Water supply pump

overvoltage

•

right place of the water supply pump

Water supply pipe not been fully attached to the

Please confirm the state of water supply pipe. If it

is normal, but still appear the malfunction signal.

please contact with the seller.

Water supply pump

over current

please contact with the seller.

• Water supply pump malfunction

Please confirm connection status

• Bad connection

• Foot control inside malfunction

If the foot control is in normal, but still show the

malfunction number, please contact with the seller.

Foot control abnormal

8-1 Protection Circuit

An electronic circuit breaker automatically functions to protect the Micromotor and the Control Unit if the

Micromotor is ever overloaded. Power supply to the Micromotor will automatically be terminated an Error code

will be displayed on the Control Unit.

◆Resetting the Protection Circuit

To reset the Protection Circuit, release and then depress the Speed Control Pedal.

8-2 Malfunction and Remedy

If the device is not working properly, please check the following table before calling our service center.

Cause of Malfunction

Remedy

Malfunction

System malfunction

•

• Memory components damaged

Memory components malfunction

Please contact with the seller

8. Care and Maintenance

Over voltage

Over current

The main unit

inside overheat

•

• Power cord short circuit

• Motor coil short circuit

Long time use under overload (over current)

• Main power cord broken

•

• Motor cord not been connected

• Motor line (signal line) malfunction

Motor sensor malfunction

Probably the circuit is bad connected.Please

connect the motor line properly. If still no

improvement,please contact with the seller.

• Water flow in to the motor

Please contact with the dealers.(in high pressure

high temperature sterilization,please be sure to

install the anti-steam dossil.

•

temperature of the main unit arise.

• To use the unit under the high temperature

environment (direct sunlight)

Due to the long time use under overload, the

Please wait until the temperature is cool down

before using.Please place it in the environment

that easy to cool down. If still no improvement,

please contact with the seller.

•

• Start and stop circuit malfunction

Abnormal voltage appears the start and stop.

In a short time repeated operation and stop,

running, inhibit suddenly accelerated circuit may

be start.Please wait for 1~2 seconds before

operation. If still no improvement, please contact

with the seller.

Probably the chuck is opened or not fully closed.

If still no improvement, please contact with the

seller.

•

• Malfunction of the motor

Malfunction of the handpiece

•

process lasts formore than 5 second.

When the Torque reaches its limit, the stop

Not malfunction. It is for the safety. It can still be

used after connect.

Braking device

malfunction

Motor sensor

malfunction

Motor running

malfunction

Fig. 18

Fig. 17

Fuse

Fuse box

8-3 Fuse Replacement

lock located on the rear of the Control Unit ). To access the Fuse,

use a pointed tool push on the fuse locking latch and the drawer

will spring open.(Fig. 15)

Internal fuse replacement:Tear down the host at the bottom of the

screw with a screwdriver tool to take out the safety device can

replace the internal fuse.

If the Control Unit does not function, check the fuses ( Fuse Box

8-4 Maintenance of the Control Unit and Foot Control

If blood or saline solution has stained the Control Unit or Foot Control, remove the AC Electrical Cord; wipe

Control Unit or Foot Control with a damp cloth, then with an alcohol-absorbed cloth.

8-5 Maintenance of the Handpiece Attachment

Every time after treatment, please put the head of the handpiece into the clean water and rotate for 4-5 seconds,

to clean the blood and physiological saline. If the attachments on the handpiece is too much, use the dry and soft

rag to wipe them out. Please do not put the whole handpiece into the water, in case of the water flow into the

handpiece from behind.

[after use, do not forget the lubrication before sterilizing under the high temperature and high pressure.]

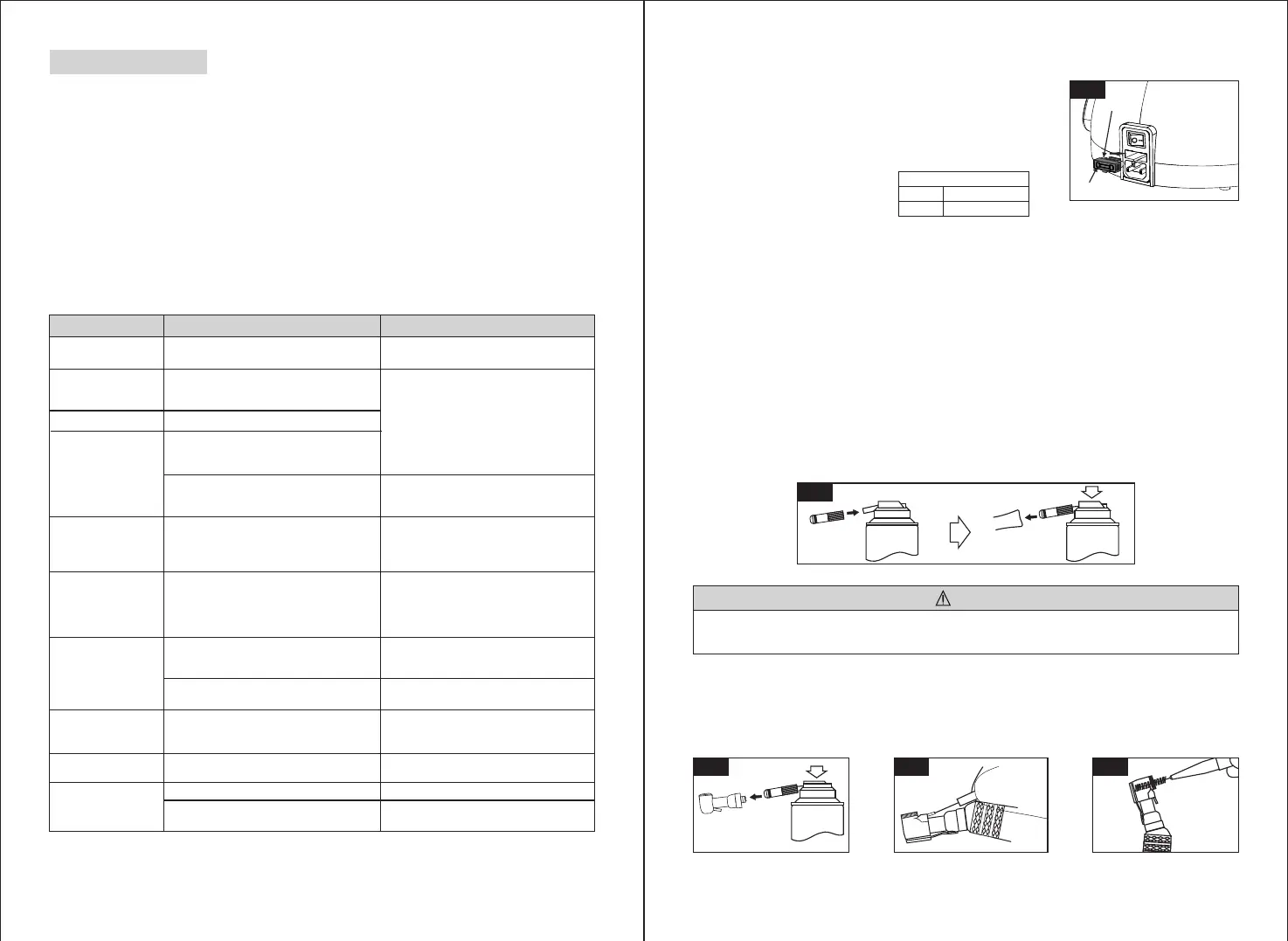

As shown in Fig. 16, put the nozzle into the handpiece behind, spray for more than 2 seconds.

Fuse Ratings

230V

F2AL 250V

F3AL 250V

120V

Fig. 15

NOTICE

When lubricating, please hold the hadnpiece tight, in case of the handpiece fly off due to the force of the spray air.

In order to make the oil and gas completely mix, please shake the tank for some time.

When lubricating, please be sure to clean up the lubrication oil tank.

If the head of the handpiece attach too much blood and dirt, need to be separately cleaned and refueled. Install

the clean nozzle to it, and wash directly from inside(Fig. 17).

If the water supply nozzle is stuck, please use the needle to clean it(Fig. 18).

If there is dirt around the nozzle, please use brush to clean it(Fig. 19).

Fig. 16

Fig. 19

Loading...

Loading...