Surface Planing

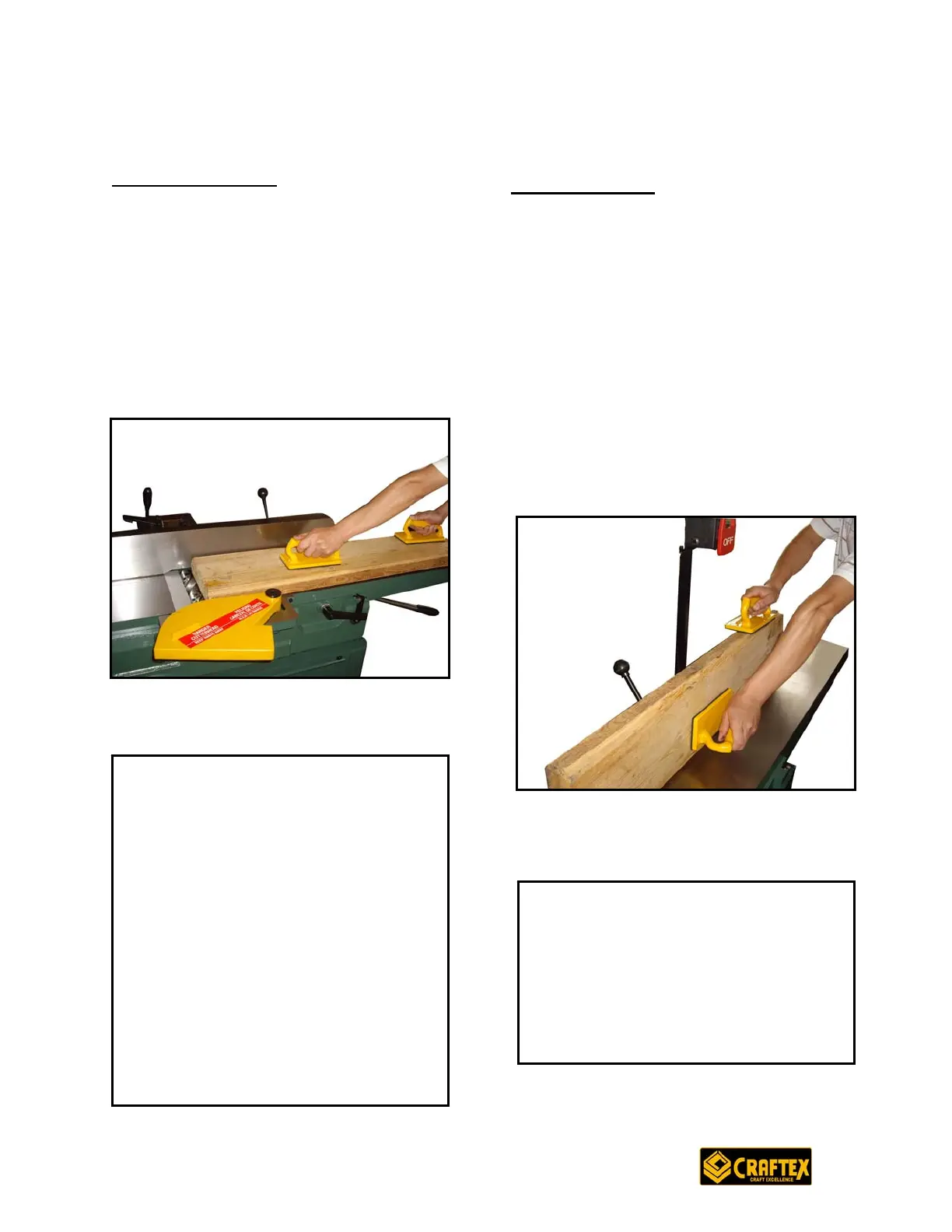

When surface planing on a jointer, make

ure the stock is free of nails, staples or

le and run

the jointer. Push the stock over the cutter

dge Jointing

s

any other object. Set the cutting depth to

1/32” and make sure the fence is set to

90 degrees. Place the concave face of

the stock flat on the in-feed tab

head with the help of push blocks. See

Figure 13

Figure 13: Surface planing

E

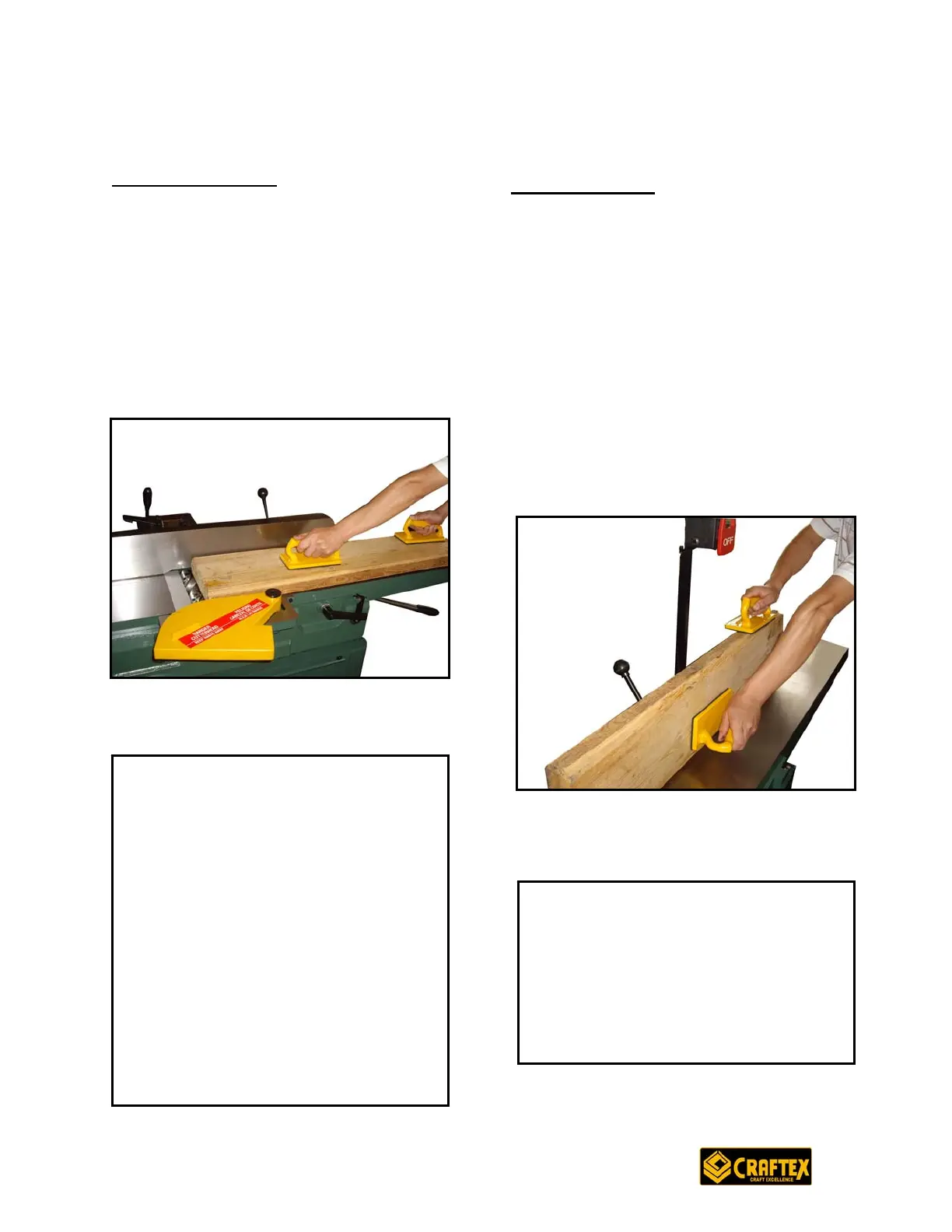

Edge jointing is to make the edge of the

tock flat a

the same

f the stock is

14: Edge Jointing

s nd suitable for joinery or

finishing. To edge joint on the jointer

make sure the stock is clean of nails,

staples or any other object. Set the

cutting depth to 1/16” & 1/8” and make

sure the fence is set to 90 degrees.

Place the concave face of the stock flat

on the in-feed table and run the jointer.

Use push blocks to push the stock over

cutter head. Repeat the

procedure until the edge o

flat.

Figure

di

kick back or there is a possibility of

B

su an and

work piece or injury to the operator.

OPERATIONS AND ADJUSTMENTS

IMPORTANT

Never plane stock against the grain

rection of the wood. It can cause a

tear-out on the wood.

efore planing stock always make

re that the stock is dry & cle

does not have nails, staples or any

other object on it.

Do not joint stock having loose knots.

It can cause a serious damage to the

IMPORTANT

To save your hands, always use

ush blocks when surface planing on

the jointer. If you fail to use push

blocks, the cutter-head touch your

hand and can cause a serious injury

to your

hand.

15

Loading...

Loading...