Table Parallelism

For the best cutting results, the in-feed

and out-feed tables of the jointer must be

paralleled to the cutter-head and to each

other.

The tables of your jointer are adjusted in

he factory. Since table parallelism

ble so that it hangs over the

utter head. Turn the eccentric bushings

just touches the cutter head.

ighten the loosen screws. See figure

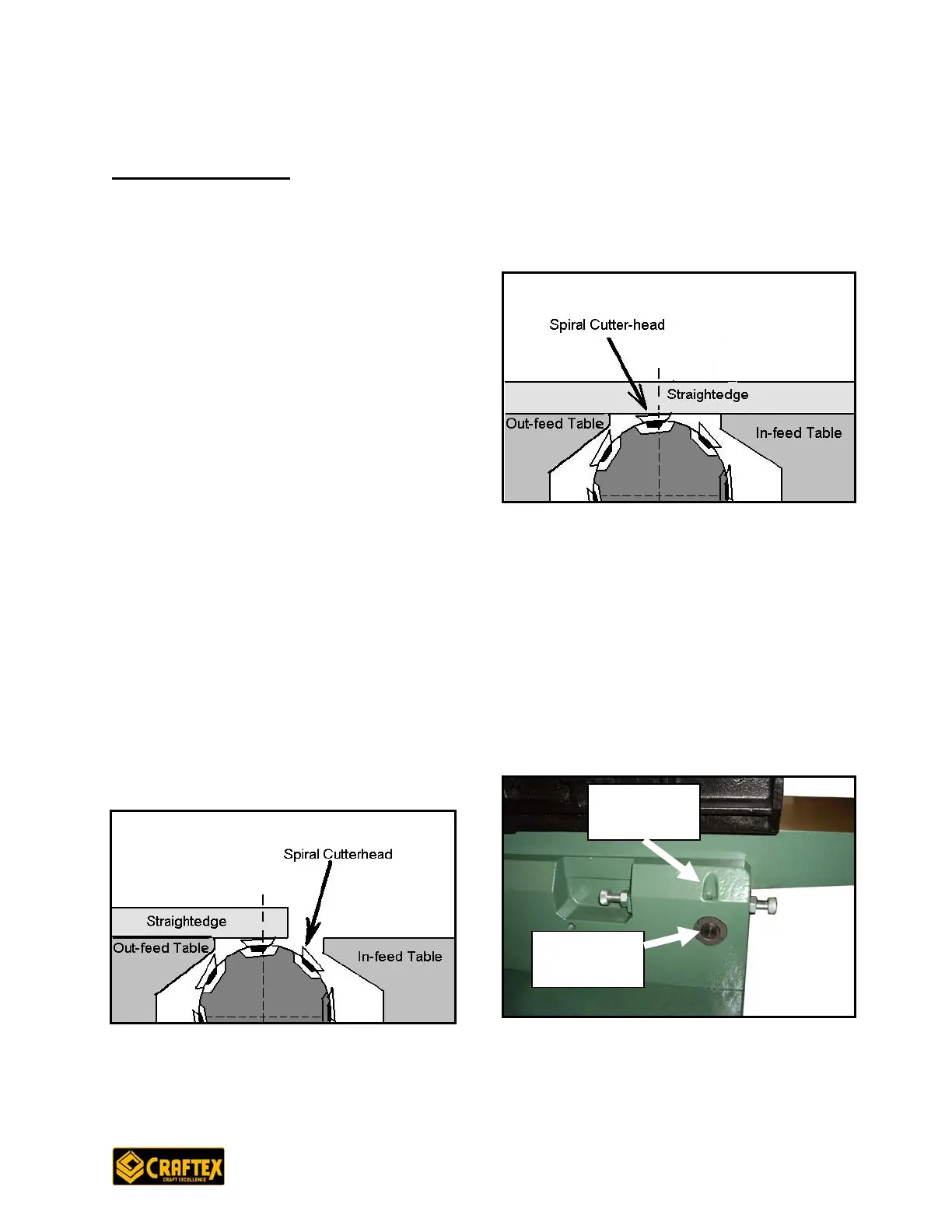

Figure 19: In-feed & out-feed table

hose set

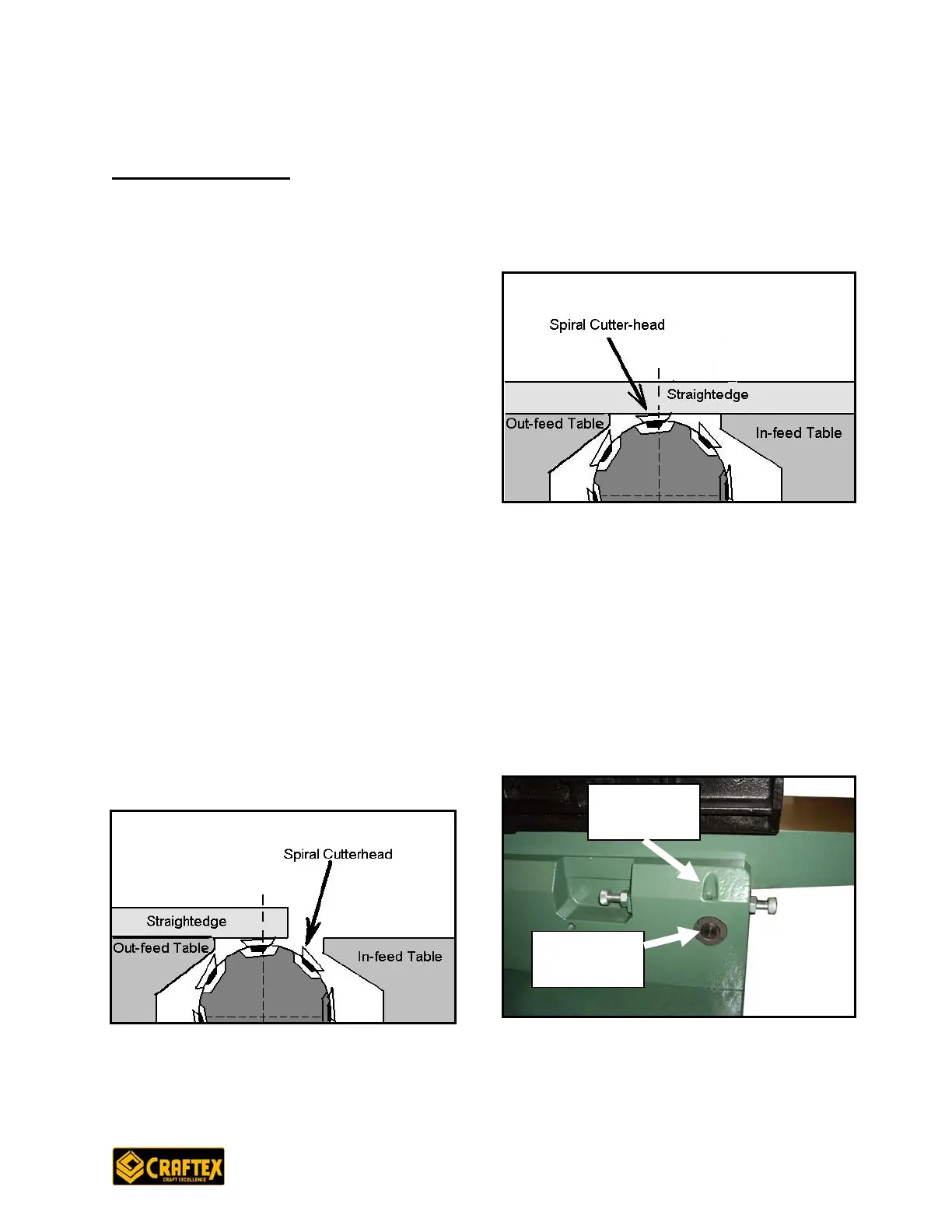

crews. Now make in-feed table parallel

igure16: Eccentric bushings and set-

Now, place the straightedge halfway

across the in-feed table and halfway over

the out-feed table to adjust the in-feed

table with the out-feed table.

t

adjustment is a complex task so it is

recommended to make sure if your table

really needs to be adjusted before you

start adjusting.

To check the table parallelism,

disconnect the power to the jointer and

remove the cutter head guard. Now,

loosen the out-feed table lock, jam nuts

and positive stop bolts (at the back of the

jointer). Remove screws in the 4

eccentric bushings located under the out-

feed table and loosen the set-screws.

Take a straight edge and place it on the

ut feed tao

c

and lower the out-feed table until the

straight edge sits flat on the out-feed

table and

T

18.

Figure 18: Adjusting out-feed table with

he cutter-head t

parallelism

Remove the screws in the 4 eccentric

bushings under the in-feed table and

loosen the screws underneath t

s

to the out-feed table by turning the

eccentric bushings under the in-feed

table. Once both tables are parallel,

tighten the set screws.

F

screws location

OPERATIONS AND ADJUSTMENTS

Eccentric

Bushing

Eccentric

Bushing

18

Loading...

Loading...