Do you have a question about the Craftsman 113.198251 and is the answer not in the manual?

Details key hazards like workpiece kickback, blade contact, wrong feed, and thrown components.

Explains the meaning of DANGER, WARNING, and CAUTION signals for risk assessment.

Provides recommendations on protective gear, clothing, and body positioning for safe operation.

Covers maintaining a safe workspace, free from children, clutter, and hazards.

Outlines essential operational safety rules for the radial arm saw.

Identifies and explains the purpose of safety labels affixed to the saw.

Initial steps for unpacking parts, identifying components, and preparing for assembly.

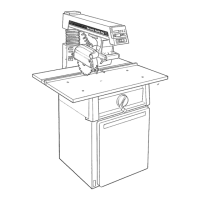

Detailed instructions for assembling the 23" cabinet for model 113.198211.

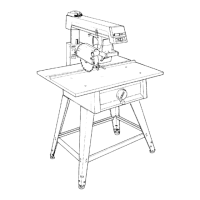

Instructions for assembling the leg set for model 113.198251.

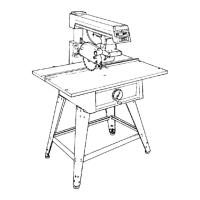

Guides for mounting the handwheel, motor, and the saw itself to the base.

Explains the operation of the power switch and the safety key.

Details on how to lock and unlock the radial arm's miter angle.

Instructions for locking and unlocking the blade's bevel angle.

Operation of controls that hold the arm position and carriage movement.

Guide to using the handwheel for adjusting the saw arm height.

Steps to ensure smooth vertical movement and proper column support.

Procedures for leveling table supports, front table, and ensuring blade squareness.

Ensuring the blade is properly aligned to the fence and table for accurate cuts.

Steps for installing and adjusting the blade guard and anti-kickback spreader.

Explains display buttons, battery installation, replacement, and error indicators.

Steps to calibrate miter and bevel encoders for accurate angle readings.

Procedure for setting zero reference points for display functions like miter, bevel, and elevation.

Details motor power, voltage, amperage, RPM, and shaft rotation.

Information on grounding, circuit needs, and proper outlet types for safe operation.

Recommendations for minimum wire size based on extension cord length.

Illustrates basic crosscut types: straight, miter, bevel, and compound.

Essential safety precautions and warnings specific to crosscutting operations.

Checklists, instructions for making table/fence kerfs, and performing cuts.

Techniques for setting up the saw to make multiple identical crosscuts.

Safe practices, workpiece positioning, and when to use in-rip vs. out-rip.

Checklists, adjustments for guards/pawls, and steps for making rip cuts.

Instructions for bevel ripping, dadoing, molding, and edging operations.

Guidance on making and using fences and push sticks for ripping.

Instructions for constructing and utilizing auxiliary fences and push blocks.

Using featherboards and auxiliary boards for crooked workpieces.

Lists recommended safety guards and other accessories compatible with the saw.

Provides definitions for technical terms and operations used in the manual.

Provides advice for achieving accurate cutting results and making frames.

A table to convert digital display decimal readings to fractions.

Addresses issues like low power, overheating, stalling, and fuse problems.

Details which parts require periodic lubrication and the type of lubricant to use.

Instructions for replacing dull antikickback pawls for safety.

Guidance on removing sawdust buildup to maintain saw performance.

Fine-tuning bevel and swivel locks for proper tension and function.

Adjusting arm fit, column support, and carriage bearings for smooth operation.

Fine-tuning miter and rip locks to ensure secure positioning.

Solves problems related to the digital display, battery, and encoders.

Addresses issues like motor not running, blowing fuses, and overheating.

Fixes inaccuracies, binding, leveling problems, and other operational faults.

Lists components for the main saw assembly, table, base, and column.

Lists components for the arm, motor, guard, yoke, and related assemblies.

Lists components for the optional cabinet and leg set.

Instructions for obtaining replacement parts and service information.

| Model Number | 113.198251 |

|---|---|

| Type | Table Saw |

| Blade Diameter | 10 inches |

| Arbor Size | 5/8 inch |

| Voltage | 120V |

| Amps | 13 Amps |

| Max Cut Depth at 90° | 3 inches |

| No Load Speed | 5000 RPM |

| Table Size | 27 inches x 20 inches |

Loading...

Loading...