Do you have a question about the Craftsman 113.198210 and is the answer not in the manual?

Understand your tool, keep it clean, use correct tools, and avoid forcing.

Maintain clean area, avoid hazards, keep children away, wear safety goggles and apparel.

Complete assembly, review safety, and check equipment before operation.

Plan work, check for damaged parts, and ensure proper setup before each use.

Highlights hazards of improper grounding, worn cords, and recommends circuit protection.

Instructions for checking the accuracy of a framing square.

Crucial warning against plugging in the power cord before assembly is complete.

Detailed list of loose parts organized by bags for Model 113.198210.

Using a framing square to ensure cabinet panels are aligned correctly.

Adjusting leveling feet for stability and proper arm slope.

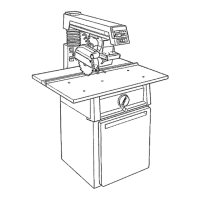

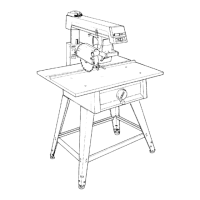

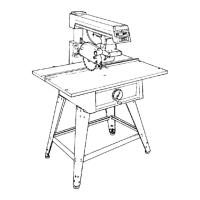

Securing the main saw unit onto the assembled cabinet.

Instructions for mounting the motor, including initial preparations.

Adjusting the column tube for smooth movement within its support.

Attaching and leveling table support channels for table-to-arm parallelism.

Adjusting front table flatness using leveling screws.

Aligning the blade to travel square to the rip fence.

Ensuring the saw blade is square to the work table.

Aligning the blade parallel to the rip fence to prevent binding.

Adjusting the anti-kickback and spreader assembly for proper function.

Procedures to align the miter encoder for accurate angle readings.

Establishing zero reference points for bevel, miter, elevation, and rip positions.

Crucial safety warnings regarding switch locking and accessory shaft usage.

Adjusting the anti-kickback and spreader assembly for proper function.

Warning to follow alignment procedures sequentially for accurate results.

Safety warnings to turn off power and remove plug before maintenance.

| Type | Table Saw |

|---|---|

| Model Number | 113.198210 |

| Blade Diameter | 10 inches |

| Motor Power | 1.5 HP |

| Voltage | 120V |

| Arbor Size | 5/8 inches |

| Amps | 15 amps |

Loading...

Loading...