Do you have a question about the Craftsman 113.213100 and is the answer not in the manual?

Comprehensive safety guidelines for operating power tools safely and preventing accidents. Includes 22 points.

Specific safety advice for drill presses, including kickback, protection, and accessory use.

Details motor specifications, RPMs, and electrical requirements for the drill press.

Defines key terms used in the drill press manual for user understanding.

Outlines motor specifications, voltage, amperage, and proper grounding procedures for safe operation.

Instructions for safely unpacking the drill press and verifying all parts are present.

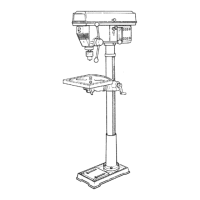

Details the location and purpose of each control and feature on the drill press for user operation.

Step-by-step guide for assembling the drill press components like base, column, head, and chuck.

Procedures for making precise adjustments to the drill press table, including squaring.

Steps for properly setting the tension of the quill return spring.

Identifies and illustrates the main components and parts of the drill press.

Core instructions for operating the drill press safely and effectively for various tasks.

Guidelines for routine maintenance and lubrication to ensure longevity and performance.

Common problems, their probable causes, and recommended solutions for drill press issues.

Visual guide and list of major components for identifying drill press parts.

Contact details and resources for obtaining repair parts, service, and support for the drill press.

| Model Number | 113.213100 |

|---|---|

| Category | Power Tool |

| Type | Table Saw |

| Blade Diameter | 10 inches |

| Motor | 1 HP |

| No-Load Speed | 3450 RPM |

| Max Cut Depth at 90° | 3-1/8 inches |

| Rip Capacity | 24 inches |

Loading...

Loading...