Do you have a question about the Craftsman 113.236090 and is the answer not in the manual?

Details the warranty terms for Craftsman benchtop tools.

Explains signal words like DANGER, WARNING, CAUTION.

Lists essential steps to complete before operating the saw.

Provides guidelines for safe installation and movement.

Covers inspection, safety checks, and maintenance before operation.

Emphasizes planning for safe operation and material handling.

Details safety gear and procedures for personal protection.

Advises on appropriate clothing and attire for safe operation.

Provides warnings and procedures while the saw is in operation.

Steps to take when finished operating or leaving the saw.

Defines essential woodworking and saw-related terminology.

Details voltage, amperage, phase, and RPM of the motor.

Covers safe electrical hookup and precautions.

Information specific to the tool's voltage and frequency.

Explains proper grounding procedures for electrical safety.

Table specifying wire gauge based on extension cord length.

Lists necessary tools for unpacking and assembly.

Steps for safely unpacking the scroll saw.

Identifies all included loose parts.

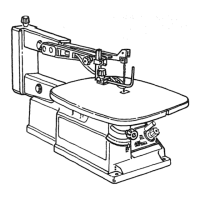

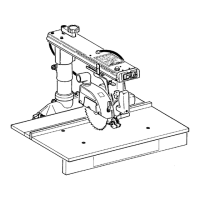

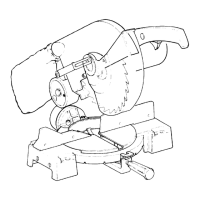

Identifies and describes the main parts of the scroll saw.

Details how to tilt the table for bevel cuts up to 45°.

Procedure to set the bevel indicator to 0° or 90°.

Instructions for adjusting the hold-down foot for workpiece stability.

Explains causes and consequences of over or under tensioning the blade.

Step-by-step guide for removing pin end blades.

Instructions for correctly installing pin end blades and setting tension.

Step-by-step guide for removing plain end blades.

Instructions for correctly installing plain end blades and setting tension.

Notes on dust blower and blade guard positioning.

Recommendations for mounting the saw to a workbench.

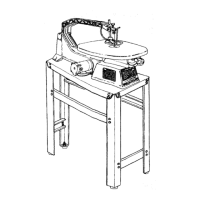

Information on mounting the saw to an optional leg set.

Pre-operation inspection and safety checks.

Guidelines for preparing workpieces and choosing blades.

Specifies allowed materials and cautions against ferrous metals.

Covers protective gear, attire, inspection, and handling tricky workpieces.

Cautions during saw operation, keeping clear, and avoiding overreaching.

Covers freeing jams, leaving the saw, usage principles, and blade selection.

Technique for making cuts inside a workpiece without cutting the perimeter.

Recommendations for blade types, sizes, and speeds.

Includes table waxing and cleaning blade holder threads.

Instructions for lubricating motor and arm bearings.

Sears recommended accessories like blades and leg sets.

Solutions for blade breaking, clamp slippage, and tension problems.

Addresses motor not running, stopping during cuts, and vibration.

| Model Number | 113.236090 |

|---|---|

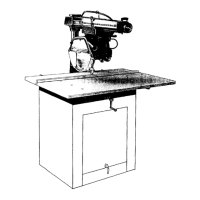

| Type | Table Saw |

| Blade Diameter | 10 inches |

| Arbor Size | 5/8 inches |

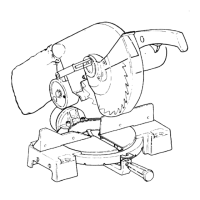

| Voltage | 120V |

| No Load Speed | 3450 RPM |

| Table Size | 20 x 26 inches |

| Max Cut Depth at 90° | 3 inches |

| Rip Capacity | 24 inches |

| Amps | 13 A |

Loading...

Loading...