Do you have a question about the Craftsman 113.234650 and is the answer not in the manual?

Steps for assembly, alignment, tool functions, and safety labels before initial operation.

Precautions to prevent injury from unexpected movement or back strain during installation or relocation.

Instructions for pre-use inspection, work planning, and wearing appropriate protective gear.

Details on motor specifications, voltage, amperage, RPM, and rotation for the saw.

Explanation of the double insulation feature for enhanced user safety.

Guidance on protecting the motor from damage due to sawdust and overload.

Essential safety warnings against plugging in the power cord and about the saw's weight during initial setup.

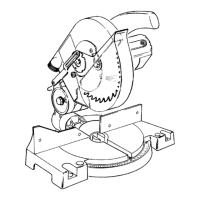

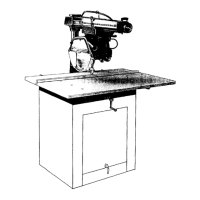

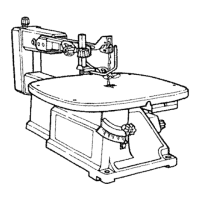

Visual identification and description of major parts and controls of the miter saw.

Detailed instructions for assembling the lower blade guard onto the miter saw assembly.

Procedure to check and adjust the blade's squareness to the saw table.

Steps to check and align the blade parallel to the turntable slot for accurate cuts.

Procedure to check and adjust the blade's squareness to the fence.

Instructions for adjusting the miter scale indicator for precise angle settings.

Adjustments for travel pivot and bevel pivot for smooth operation and alignment.

Explanation and adjustment of the depth stop for controlling blade travel.

Guidance on maintaining maximum cutting capacity by checking blade clearance and depth stop.

Details on front and rear fence positions for various cutting applications.

Explanation of the trigger switch and its lock-off button for safe operation.

Step-by-step instructions for safely removing and installing the saw blade.

Crucial warnings about blade installation, clearance, and the necessity of the mounting plate.

Essential safety warnings regarding saw movement and handling during mounting.

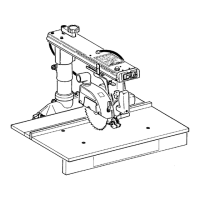

Guidance on mounting the saw to a 3/4 inch plywood board for portability.

Instructions for mounting the saw to the catalog leg set, including hardware details.

Mandatory reading and pre-operation checks including safety gear and blade selection.

Critical warnings for safely cutting aluminum or other non-ferrous metals.

Checks for blade rotation, sharpness, alignment, and arbor collar security before operation.

Guidelines for proper workpiece support, handling various sizes, and avoiding freehand cuts.

Instructions to clear the table and personal safety measures to prevent entanglement.

Critical safety precautions to follow while the saw is in operation, including body positioning.

Instructions on how to perform a miter cut, including fence position notes.

Instructions on how to perform a bevel cut, including recommended stance.

Procedure for performing a compound cut, requiring both bevel and miter adjustments.

Guidance on how to properly position and cut bowed workpieces to avoid pinching.

Recommendations for using supports for long workpieces to ensure stability and safety.

Information on using an auxiliary fence for specific molding cuts, including its limitations.

Methods and instructions for using filler blocks to cut crown moldings at specific angles.

Instructions for performing vertical bevel cuts on workpieces using a spacer.

Procedures for replacing carbon brushes and caring for the lower blade guard.

Guidance on managing sawdust and using recommended accessories safely.

Information regarding lubrication requirements for the saw's moving parts.

Critical caution advising qualified technicians for mechanical assembly and spring handling.

Instructions on how to order replacement parts, including required information.

Loading...

Loading...