Do you have a question about the Craftsman 113.234701 and is the answer not in the manual?

Details major hazards, outfeed zone, kickback, wrong way feed, and general safety principles.

Covers safe practices for users, the work environment, and operating the saw itself.

Safety guidelines for handling workpieces, blades, and understanding on-product warnings.

Lists all included parts and the tools needed for assembly and alignment.

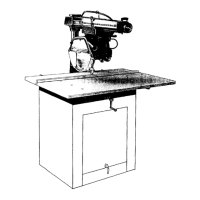

Detailed instructions for assembling the saw's base, frame, and radial arm.

Steps for attaching table supports, the front table, and assembling the miter lock.

Instructions for installing rip scale indicators, table clamp screws, and the dust elbow.

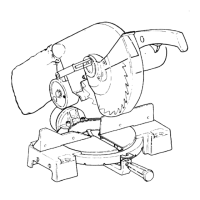

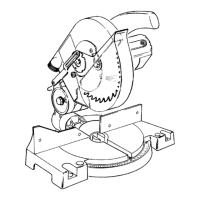

Details on-off switch, yellow key, elevation handle, rip/bevel locks, and indicators.

Explanation of swivel lock, miter lock, index pins, and table clamp screw functions.

Functionality of pawls, spreader, hold down lock, and hold down for safe operation.

Importance of alignment and the initial steps using essential tools.

Steps for adjusting carriage bearings, column support, and leveling the front table.

Procedures to square the blade to the table/fence and calibrate scale indicators.

Details on motor power, voltage, amperage, and required power supply connection.

Recommendations for selecting and using extension cords safely and effectively.

Explains crosscutting technique and fundamental safety measures.

Details risks like thrown chips, workpieces, and how to mitigate them.

Step-by-step guides for straight, miter, bevel, and compound crosscuts.

Summaries of safety points and tips for efficient crosscutting.

Explains ripping, blade positions (in-rip/out-rip), and feed directions.

Focuses on critical dangers like kickback, wrong feed, and outfeed zone hazards.

Detailed steps for preparing the saw and executing rip cuts safely.

Guidance on using push sticks and push blocks for safe ripping.

Instructions for making and using fences and push sticks for various cuts.

Details on making and using these aids for narrow cuts and workpiece control.

How to attach straight edges to workpieces for safer ripping.

Safety guidelines for accessories and specific instructions for the lower blade guard.

Catalog of optional accessories designed for this radial arm saw.

Basic upkeep, cleaning procedures, and lubrication points for the saw.

Instructions for adjusting bevel lock, swivel lock, miter lock, and others due to wear.

Procedures for replacing motor brushes and changing the saw blade.

Diagnosing and resolving issues related to motor performance and cut accuracy.

Addressing issues with blade travel, table leveling, and control lock functionality.

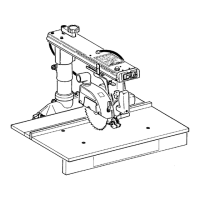

Diagram and numbered list of parts for the main saw assembly.

Diagram and numbered list of parts for the radial arm and carriage assembly.

Diagram and numbered list of parts for arm, table, and control mechanisms.

Diagram and numbered list of parts for safety features like pawls and spreader.

| Model Number | 113.234701 |

|---|---|

| Type | Table Saw |

| Blade Diameter | 10 inches |

| Arbor Size | 5/8 inch |

| Motor | Induction |

| Voltage | 120V |

| No Load Speed | 3450 RPM |

| Max Cut Depth at 90° | 3 inches |

| Table Size | 27 inches x 20 inches |

| Rip Capacity | 24 inches |

Loading...

Loading...