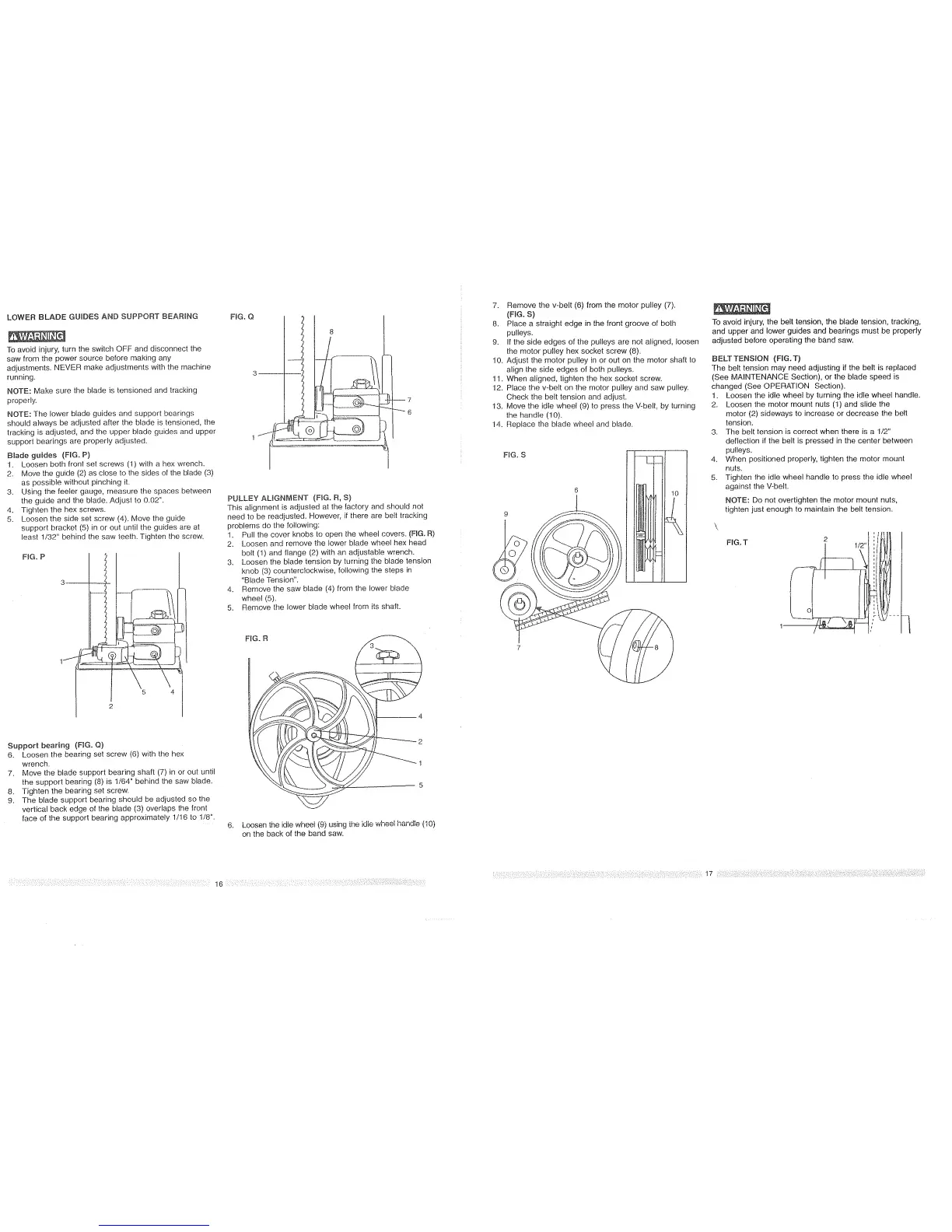

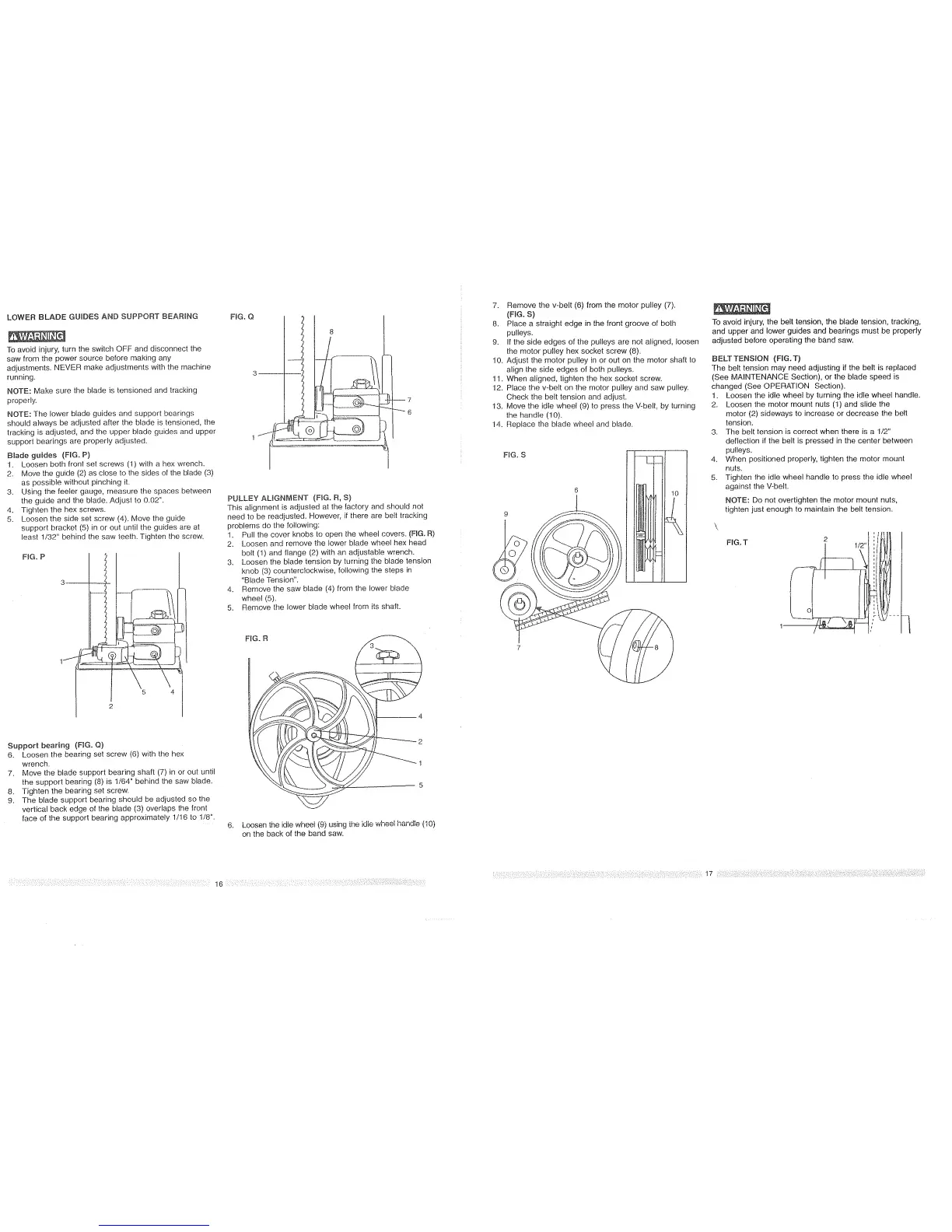

LOWER BLADE GUIDES AND SUPPORT BEARING

To avoid injury, turn the switch OFF and disconnect the

saw from the power source before making any

adjustments. NEVER make adjustments with the machine

running.

NOTE: Make sure the blade is tensioned and tracking

properly.

NOTE: The lower blade guides and support bearings

should always be adjusted after the blade is tensioned, the

tracking is adjusted, and the upper blade guides and upper

support bearings are properly adjusted.

Blade guides {FIG. P)

1. Loosen both front set screws (1) with a hex wrench.

2. Move the guide (2) as close to the sides of the blade (3)

as possible without pinching it.

3. U,Cing the feeler gauge, measure the spaces between

the guide and the blade. Adjust to 0.02".

4. Tighten the hex screws.

5. Loosen the side set screw (4). Move the guide

support bracket (5) in or out until the guides are at

least 1/32" behind the saw teeth. Tighten the screw.

FIG. P

3 .......

i

i j

FIG, Q

8

f

7

6

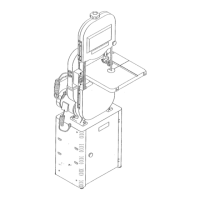

PULLEY ALIGNMENT {F}G. R, S)

This alignment is adjusted at the factory and should not

need to be readjusted. However, if there are belt tracking

problems do the following:

1. Pull the cover knobs to open the wheel covers. (F}G. R)

2. Loosen and remove the lower blade wheel hex head

bolt (1) and flange (2) with an adjustable wrench.

3. Loosen the blade tension by turning the blade tension

knob (3) counterclockwise, following the steps in

"Blade Tension".

4. Remove the saw blade (4) from the lower blade

wheel (5).

5. Remove the lower blade wheel from its shaft.

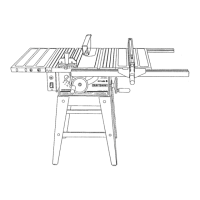

7. Remove the v-belt (6) from the motor pulley (7).

(FIG. S)

8. Place a straight edge in the front groove of both

pulleys.

9. tf the side edges of the pulleys are not aligned, loosen

the motor pulley hex socket screw (8).

10. Adjust the motor pulley in or out on the motor shaft to

align the side edges of both pufteys.

1t. When aligned, tighten the hex socket screw.

12. Place the v-belt on the motor pulley and saw pulley.

Check the belt tension and adjust.

t3, Move the idle wheel (9) to press the V-belt, by turning

the handle (10).

14. Replace the blade wheel and blade.

FIG. S

10

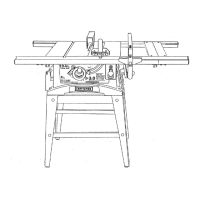

To avoid injury, the belt tension, the blade tension, tracking,

and upper and lower guides and bearings must be properly

adjusted before operating the ba_ndsaw.

BELT TENSION {FIG. T)

The belt tension may need adjusting if the belt is replaced

(See MAINTENANCE Section), or the blade speed is

changed (See OPERATION Section).

1. Loosen the idle wheel by turning the idle wheel handle.

2. Loosen the motor mount nuts (1) and slide the

motor (2) sideways to increase or decrease the belt

tension.

3. The belt tension is correct when there is a 1/2"

deflection if the belt is pressed in the center between

pulleys.

4. When positioned properly, tighten the motor mount

nuts.

5. Tighten the idle wheel handle to press the idle wheel

against the V-belt.

NOTE: Do not overtighten the motor mount nuts,

tighten just enough to maintain the belt tension.

\

F_G. T

t_) frfd/I

!

Support bearing (FIG. Q)

6. Loosen the bearing set screw (6) with the hex

wrench.

7. Move the blade support bearing shaft (7) in or out until

the support bearing (8) is 1/64" behind the saw blade.

8. Tighten the bearing set screw.

9. The blade support bearing should be adjusted so the

vertical back edge of the blade (3) overlaps the front

face of the support bearing approximately 1/t6 to t/8".

2

t

5

6. Loosen the idie wheel (9) using the idle wheet handle (I0)

on the back of the band saw.

Loading...

Loading...