2.11

Pinto BT-POM 1212 - Revision 5

Section 2 Hook-up

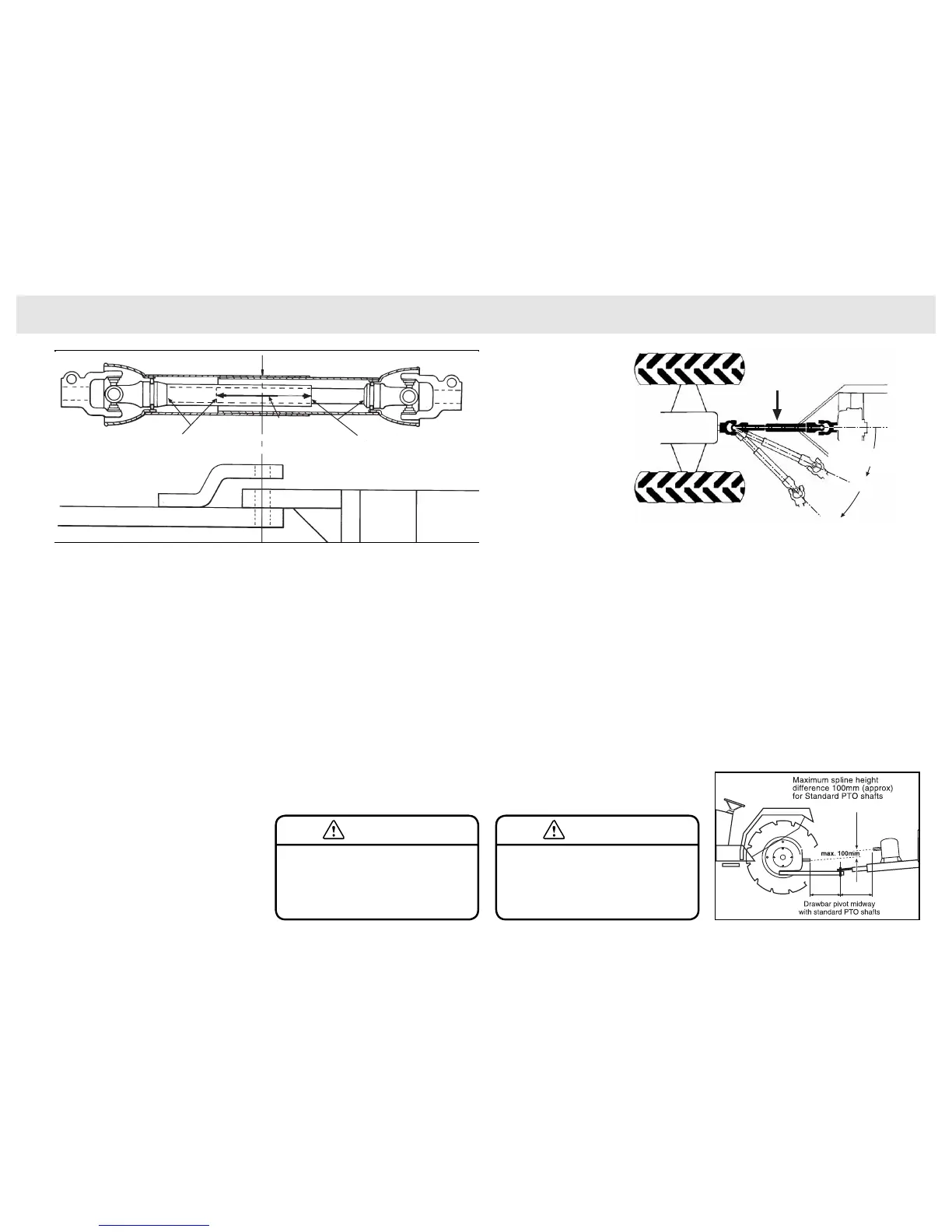

Minimum shaft

contact length

of 300mm (12")

(Do not cut shaft

too short)

Make sure shaft ends

do not butt up.

(Do not cut shafts too long)

Tractor hitch

Sprayer

hitch

Make sure shaft ends

do not butt up.

(Do not cut shafts too long)

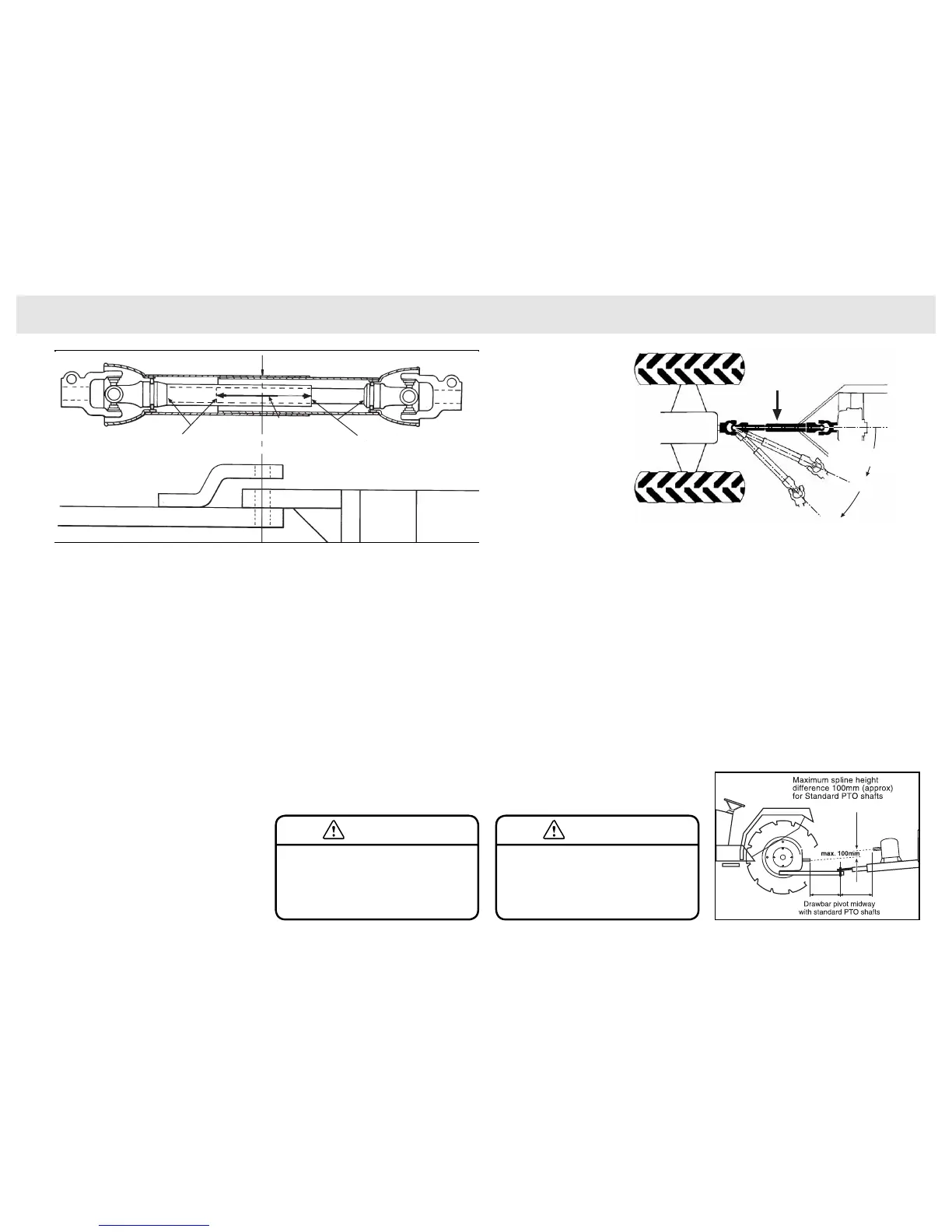

On Standard PTO shafts, the drawbar pin connecting the tractor & Pinto should be centred between the two universal

joints of the PTO shaft.

25°

45°

Maximum Intermittent

Turning Angle

Maximum

Operating Angle

Pivot point of tow hitch

centred between

PTO universal joints

Standard PTO

Important Factors when

Fitting the PTO Shaft

The following three factors must be

correct to avoid pump damage and

maximise PTO operating life:

1 When travelling straight ahead, the

point at which the sprayer drawbar

pin is joined to the trac tor should be

halfway between the universal

joints of a Standard PTO shaft, as

illustrated.

The tractor is then able to make

maximum turns with minimal

bending of the universals.

2 When the tractor is towing the

sprayer straight ahead, the two

telescopic sections of the power

take-off shaft are at maximum

extension.

When turning or crossing an

inversion, the telescopic shaft

sections close up.

3 The height difference between the

tractor PTO spline and the PTO

spline of Pinto should not be

more than 100mm.

This ensures PTO joint angles are

approx equal and do not exceed

limits. If greater than 100mm, a wide

angle (constant velocity) PTO should

be used. See Hitch height adjustment

instructions on page 2.10.

Standard PTO Operating Lim its

Heed the Operating Limits

of the Standard PTO Shaft

The standard Pinto is fitted with a

STANDARD PTO shaft.

The maximum intermittent turning

angles of the Standard PTO shaft is only

recommended where should not exceed

45° turning angle of the PTO.

Standard PTO Operating Lim its

Ensure that the drive shaft is the correct length to

avoid any "butt up" damage to the pump.

CAUTION

Pump warranty is not valid for damage caused

by incorrect PTO shaft mounting.

CAUTION

AA

Follow the instructions below to fi t the PTO

shaft onto the Pinto after transit:

1 Remove the PTO shaft which is

strapped to the Pinto frame.

2 Check the PTO shaft has not been

damaged in transit.

3 Measure and fi t the PTO to the Pinto

ensuring the locking pin is correctly

located. Make sure you read and

understand “The important factors

for fi tting the PTO shaft” on the next

page.

4 Grease the universal joins and

telescoping shafts.

5 Fit the PTO to the Pinto ensuring the

locking pin is correctly located.

6 Before operating the drive shaft, be

sure that all safety guards are in

place.

Loading...

Loading...