5.7

Pinto BT-POM 1212 - Revision 5

Section 5

Diaphragms, Straps & Foam Markers

Non-Drip

Diaphragms

Non-drip diaphragms should be cleaned

regularly to prevent dripping from

nozzles.

To clean the non-drip diaphragms:

1 Completely stop all sprayer functions.

2 Unscrew and remove the diaphragm

cap.

3 Remove and clean any sediment Off

the diaphragm membrane.

Replace the diaphragm membrane if

damaged.

4 Refi t the diaphragm.

5 Refi t the diaphragm cap and carefully

tighten.

Remove & clean the non-drip diaphragms regularly.

Do not over tighten the diaphragm cap. Over

tightening the cap may impede fl ow through the

diaphragm.

NOTE

Foam Marker

Main te nance

Salvarani Double Sided

Foam Markers

Pressure relief valve

The pressure relief valve on the tank cap

needs no maintenance.

Operating the pressure discharge ring

under the tank cap prevents incrustations

forming on the pressure relief valve at the

same time checks its effi ciency.

Machine Down for Up to 7 Days

For periods of inactivity of at most 7 days,

carry out the following operations:

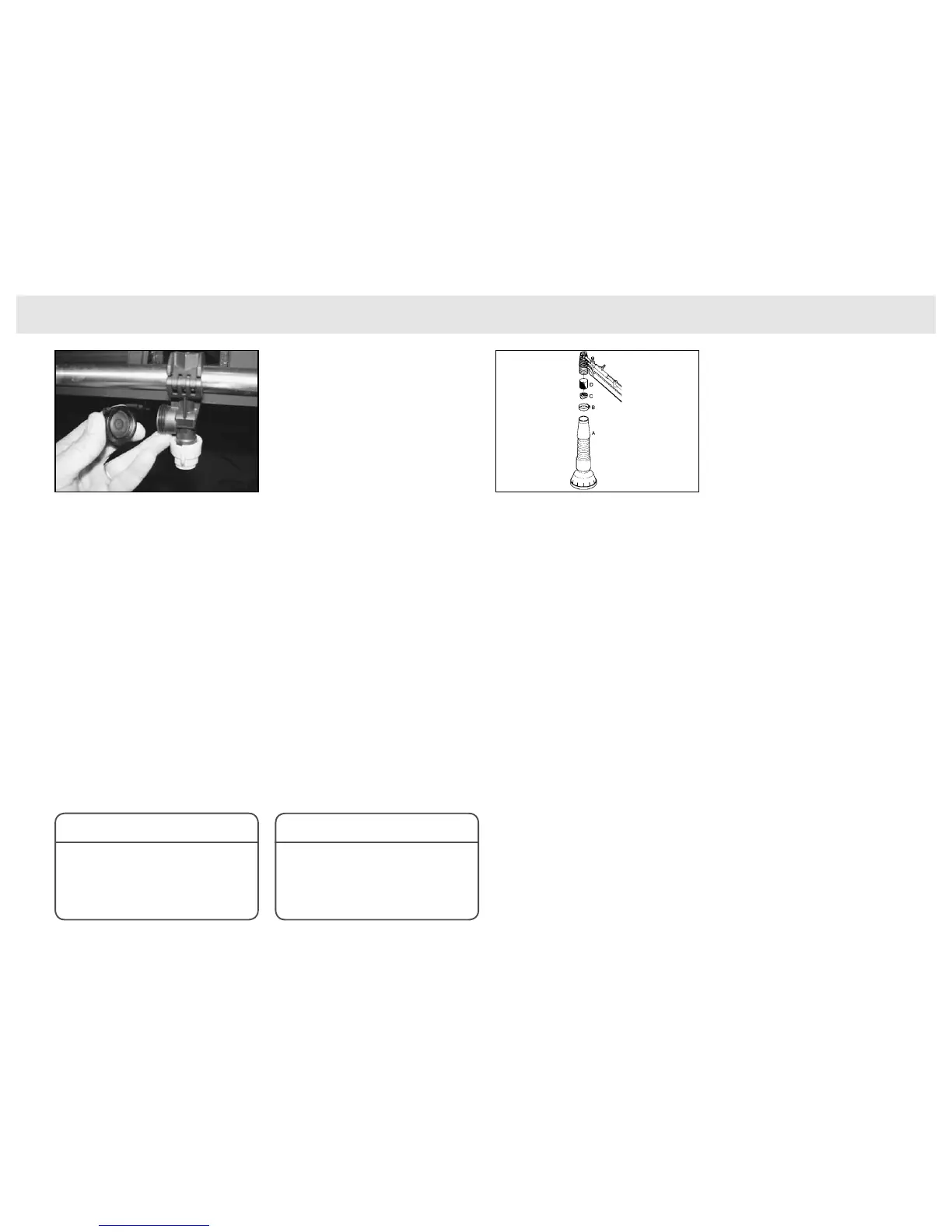

• Slacken the band “B” and remove

the diffusor “A”.

• Remove the grid “C” turning it

anticlockwise.

• Take the sponge “D” out of the

foam nozzle.

• Carefully wash the foam diffusers

and sponge with water.

Weekly Cleaning (Figure 11).

Tank clamps should be checked two or three

times a day when the sprayer is new and the tank

and frame are bedding-in.

Thereafter, the tank clamps should be checked

regularly.

NOTE

• Reassemble the parts, taking care

when inserting the sponge

that must go freely into its seat

without crushing that would alter

the operation of the foam marker.

• Repeat the above operations for

the other foam nozzle as well.

Loading...

Loading...