5.8

Pinto BT-POM 1212 - Revision 5

Lubrication & Maintenance

Machine Down for Up to 30

Days

For periods of inactivity of at most 30

days, carry out the following operations:

• Slacken and remove the cap “C”

• Remove the screws “A” and take

off the tank bracket “B”.

• Remove the tank and wash with

clean water.

• Wash the bottom fi lter “D”.

• Insert the tank into the support

bracket.

• Add a few litres of water into the

tank, put the cap back on.

• Restore the electrical connections.

• Wash the hydraulic circuit,

operating alternately the lever

selector in the position

corresponding to the boom section

involved until clean water comes

out of the diffusers.

• Slacken and remove the cap,

empty the tank of the remaining

water.

• Dismantle the waterlair pipes from

the cap and join them using the

section of pipe supplied as shown

in the frame 12/A.

• Empty the hydraulic circuit by

operating the lever selector in the

position corresponding to the

boom section involved until only air

comes out of the diffusors.

• Fit all the parts back together to

restore the initial conditions.

• Carry out the operations described

in the “Machine down for up to 7

days” paragraph.

Foam Markers

Machine Down for Longer than

30 Days

For long periods of inactivity, proceed as

follows:

• Carry out the operations described

in the “Machine down for up to 30

days” paragraph.

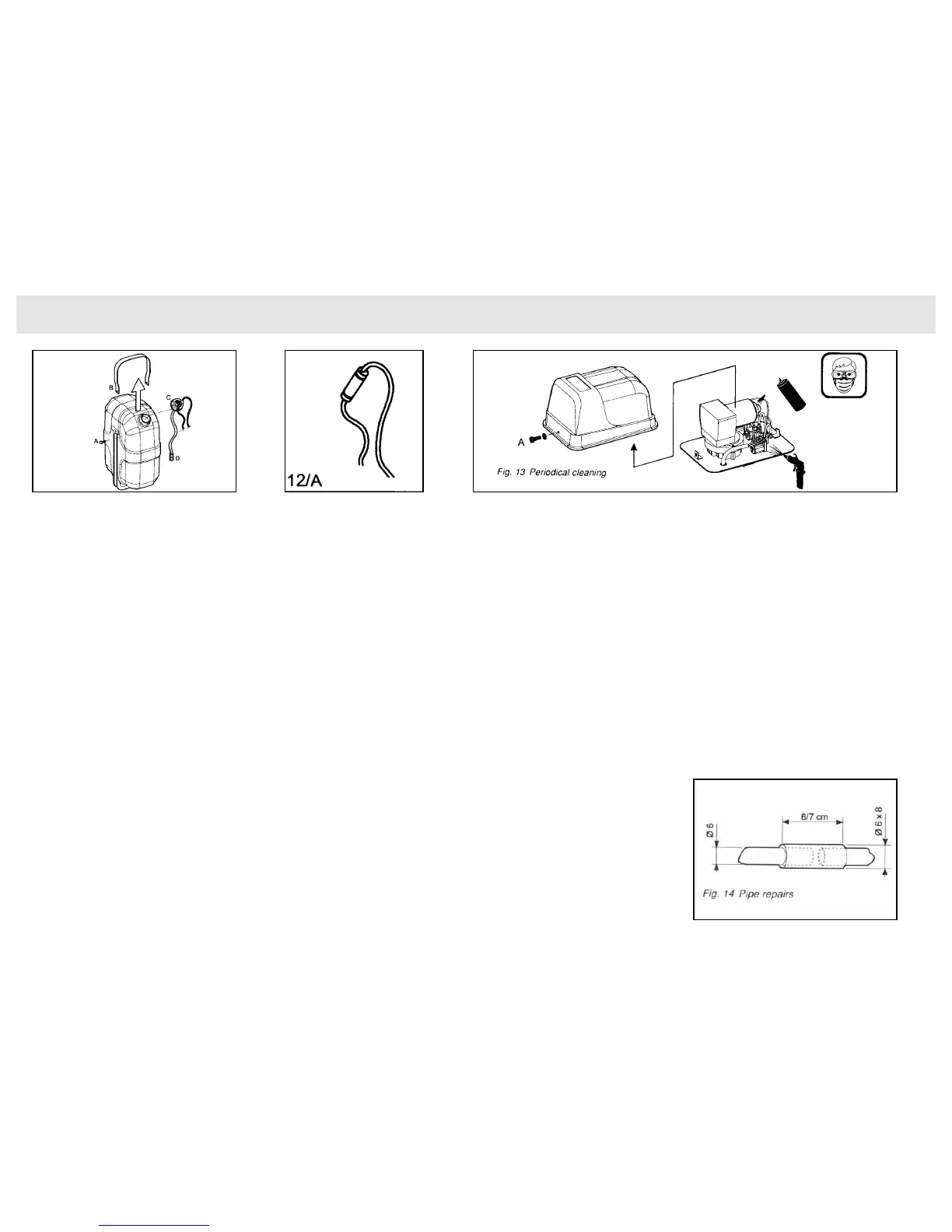

• Clean the electric compressor unit:

• Remove the cover by taking out

the screws “A”;

• Clean the inside with compressed

air (wearing a face-mask and

safety goggles);

• Spray the self-cleaning liquid for

electrical contacts through the

slots on the electric motor;

• Fit the cover back on.

• To ensure dense and lasting

formation of foam, replace the

sponges code 520000.160 (D, Fig.

11) every year.

Pipe Repairs

If the pipes burst, do the repair using a

section of pipe diameter 6 (inside) x 8

(outside), supplied in the outfi t.

Monthly Cleaning (Figure 12). Periodical Cleaning (Figure 15).

Pipe Repairs (Figure 14).

Loading...

Loading...