Form I-RA/D 350/500, P/N 131090R12, Page 27

Inspecting and

Cleaning the

Heat Exchanger

Tubes,

Combustion

Chamber, and

Flue Pipe

Inspecting Model

RA/RAD 350

WARNING: Used oils may contain engine-wear metal

compounds and foreign materials. When burned, these

compounds are deposited within or exhausted from

this heater. Therefore, care should be taken when

using, cleaning and maintaining this equipment.

Whenever any cleaning, including the ue pipe and exhaust stack is

done, proper protective equipment, including gloves and a face mask or

respirator, must be worn.

WARNING: Turn off electric power before inspecting

or cleaning the unit. Allow unit to cool.

Model RA/RAD 350 - To determine need for cleaning, inspect the heat

exchanger tubes through the access door on the end of the heater op-

posite the burner.

• Turn the four outer door latches 1/4 turn.

• Remove the door panel by lifting upward and outward on the

door handle.

• Using a 1/2” wrench, remove the nuts and washers from the

inner hinged door (See NOTE in the margin). Open door.

• Shine a ashlight into the heat exchanger. As little as 1/16” ash

build-up on the internal tube surfaces can dramatically decrease

the thermal efciency of this heater. If the ash build-up is over

1/16”, leave the door open and proceed with the cleaning.

NOTE: You cannot adequately make this determination through the ame

observation door. The majority of the settlement of ash accumulates in

the heat exchanger tubes.

Combustion

Chamber

Inspect Heat

Exchanger

Tubes

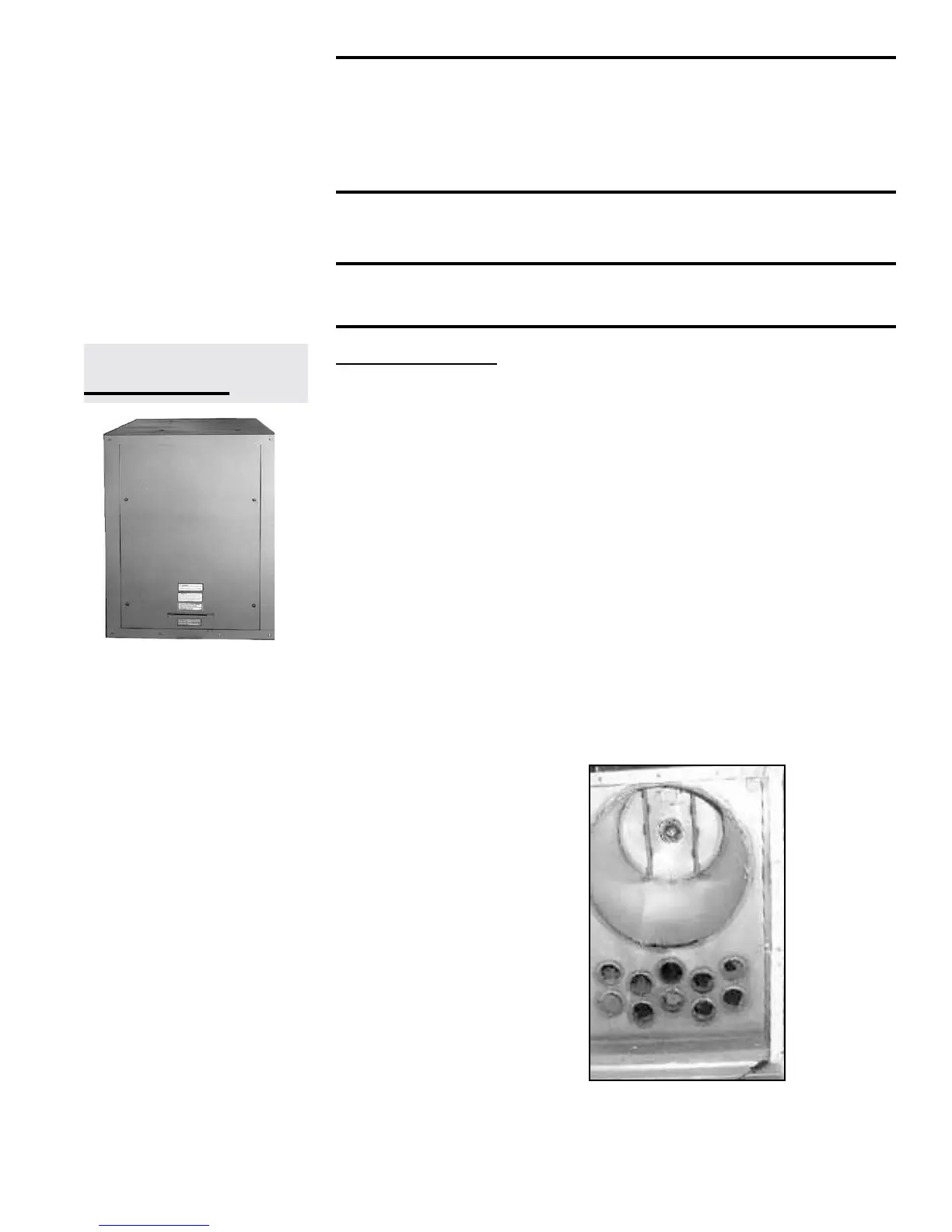

Button hole type woven

ceramic gasket is used

between all mating

parts.

View of an RA/RAD 350 with Hinged Inner Door Open

Turning Box End

NOTE: Prior to 5/02, Size

350 had a two-piece door

with a cross support in the

middle. The door sections

are not hinged and must

be completely removed for

inspection and service.

Loading...

Loading...