Form I-RA/D 350/500, P/N 131090R12, Page 37

Oil Burner Troubleshooting

To diagnose malfunctions properly, the following test equipment is re-

quired:

1) An electrical test meter that can measure AC volts, ohms, and

amps;

2) A combustion analyzer kit to measure oxygen and/or carbon

dioxide, smoke, stack temperature, and draft; and

3) Two pressure gauges with scales of 0-100 PSIG and 0-30 PSIG.

Before test ring any heater, check the combustion chamber for an

excessive accumulation of unburned oil and restore to safe condition

before ring.

WARNING: Do not attempt to start the burner when

excess oil has accumulated, when the furnace is full of

vapor, or when the combustion chamber is very hot.

NOTE: Refer to the troubleshooting guide on page 38 to select the ap-

propriate troubleshooting chart.

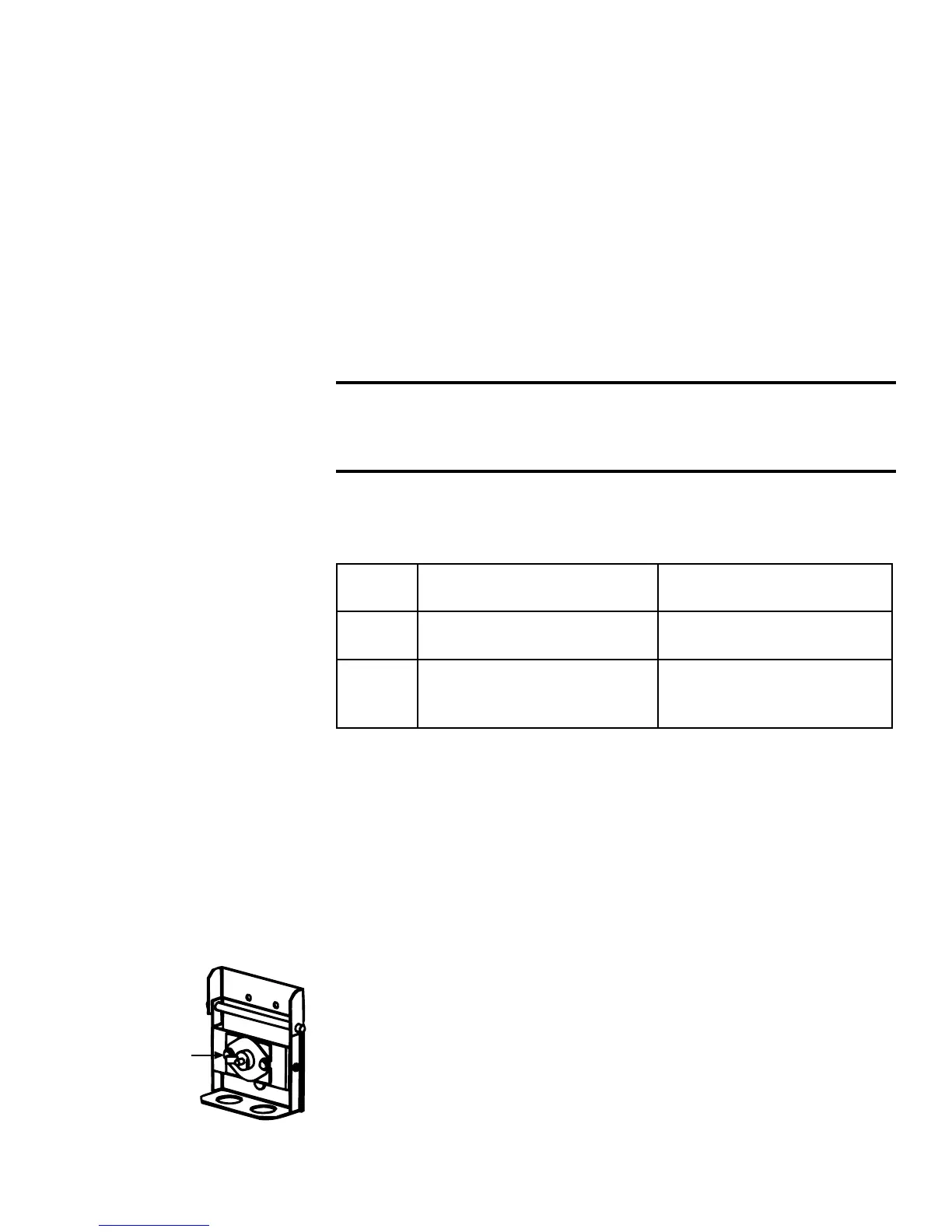

Check the Indicator Lights

Light

Location (on the Electrical

Box)

Function

GREEN On the side next to discon-

nect (on/off) switch

Indicates that the main

power is on to the heater

GREEN On the xed-cover portion

above the ignition controller

Indicates that all limits have

been satised and the unit

is ready to operate

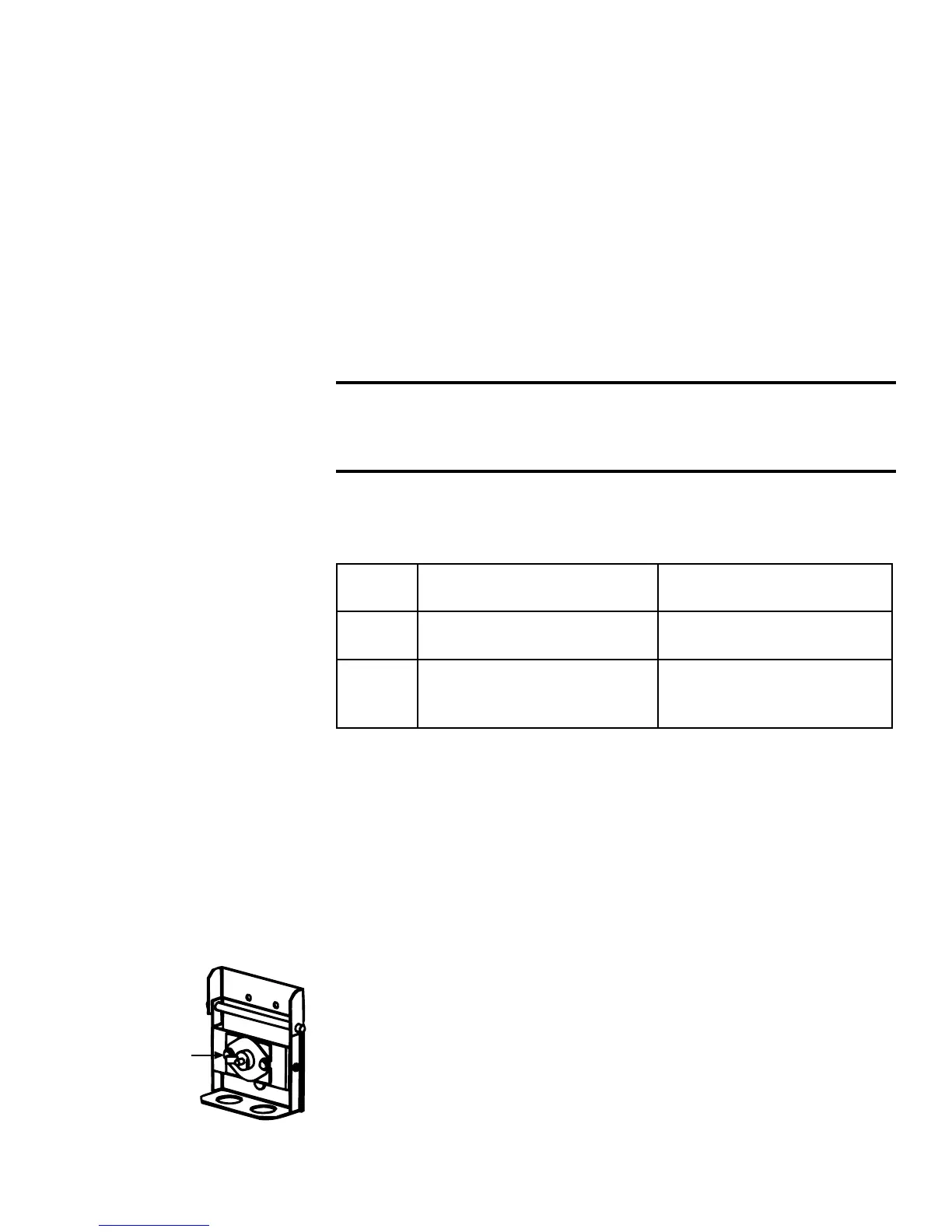

Troubleshooting

Viewport Cover

Backow

Sensor Switch

Description/Application - The backow sensor is a temperature-sen-

sitive switch that is designed to shutdown the heater when there is a

positive pressure in the combustion chamber The heater is designed to

operate with an overre draft of -0.01” to -0.02” w.c. Prolonged operation

at a positive pressure (

equal to or greater than 0.00” w.c.) can cause

overheating and accidental component failure. Undesirable positive

furnace pressure can be caused by any one or a combination of the fol-

lowing conditions:

• Totally or partially blocked ue gas venting system

• Improperly designed venting system

• Improper fuel-to-air ratio for combustion

• Excessive ash buildup on interior heat exchanger surfaces

• Blocked heat exchanger passages

• Improper atomization of the fuel

• Plugged or defective fuel nozzle

• Improperly adjusted fuel nozzle assembly

• Burning off-specication fuel

• Changes in outside ambient temperature

Loading...

Loading...