1. On carbon saddle post and/or saddle

stem

•

Apply assembly paste to the saddle post

and to the inside of the seat tube and only

use assembly paste for carbon parts for this

procedure.

•

Saddle post and seat tube must not be

greased. Only carbon assembly paste may

be used.

•

Saddle posts made of aluminium may only

be tted using a carbon assembly paste.

2. Push the saddle complete with saddle

post into the frame seat tube until the

desired saddle height is obtained. In this

position the lower end of the saddle post

must be a minimum of 10 cm below the

lower edge of the top tube.

Do not rely on the marking on the saddle

post.

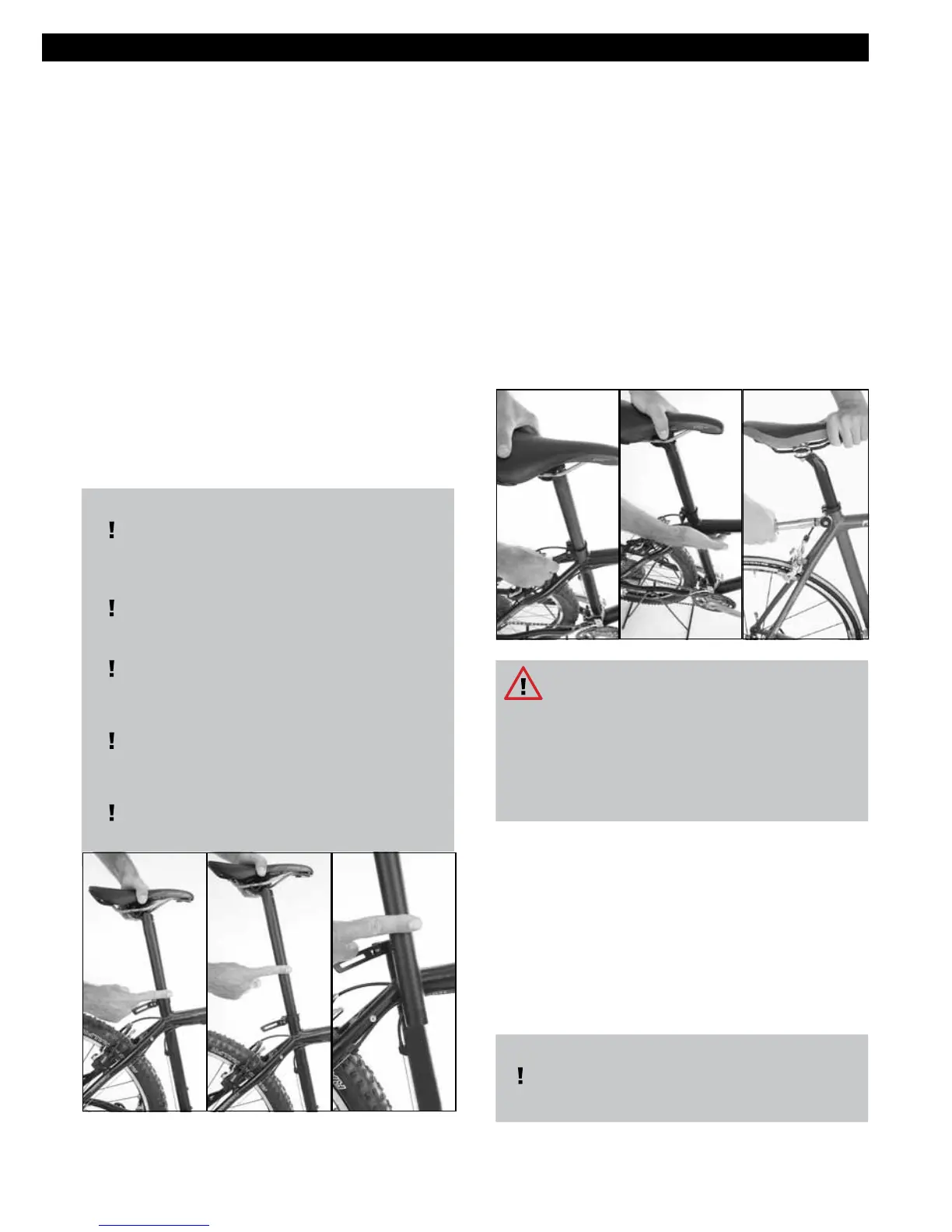

To check the correct insertion distance:

Hold a nger tip against the saddle post

when tted directly above the clamp.

Keep your nger tip in this position and

withdraw the saddle post from the seat

tube.

Hold the saddle post laterally beside the

seat tube so that your nger is again level

and directly above the clamp.

In this position the lower end of the

saddle post must be a minimum of 10 cm

below the lower edge of the top tube.

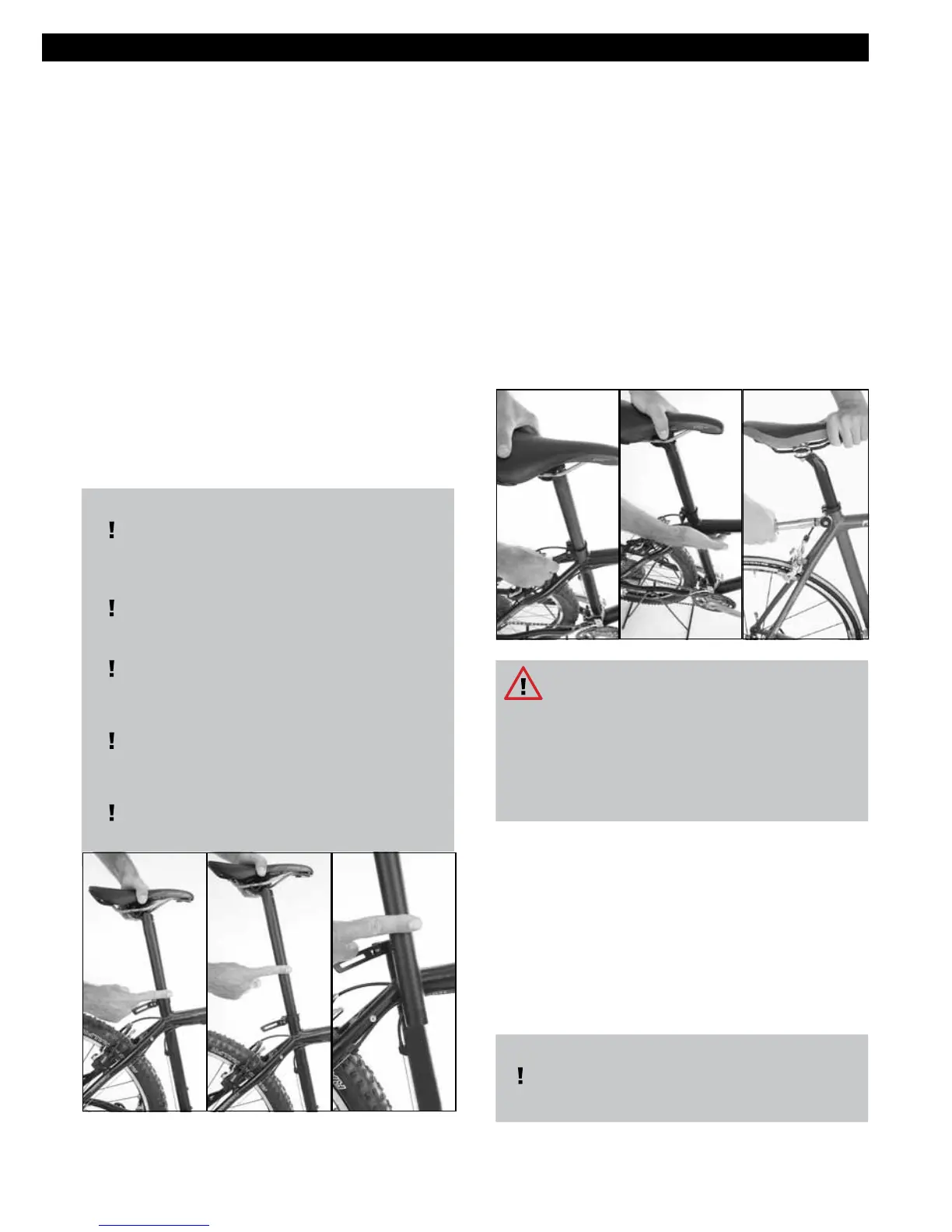

3. Turn the saddle so that the saddle points

in the direction of travel.

4. Ensure that the clamp is ush in the

frame and that the seat tube slots and the

clamp are covered.

5. Close the quick release as per Chapter 8.8

or tighten the Allen screw with a torque

wrench.

Please observe assembly instructions

and the specied torque in the accompa-

nying component instructions indicated

in table 3.3.

Risk of Personal Injury and

Material Damage!

An over-tightened carbon bre saddle

post can break when riding and lead

to dangerous riding situations, falling,

accidents and material damage.

•

The seat tube clamp must be tightened rm-

ly in order to prevent the saddle post from

lowering into the frame or laterally twisting

during the ride.

•

If the saddle post does not remain in the

desired position, even though you have

reached the maximum admissible tighte-

ning torque, please consult your specialist

dealer immediately.

Please observe assembly instructions

and the specied torque in the accompa-

nying component instructions

Loading...

Loading...