58 Culligan® CSM Series Softeners

58 Cat. No. 01016370

Application Problems

Many service problems are not due to equipment malfunction, but rather to misapplication or environmental conditions.

The Operation & Performance Specifications

(page 2 of this manual) provides the limits of water characteristics for the CSM Series water softeners. If the water

characteristics fall outside these limits, additional water treatment equipment may be required, or the water characteristics

should be brought inside the limits. The system ow rates and exchange capacities are also listed.

Appendix A, "Table 14. CSM Series Water Softeners - Flow Rate Data (GPM)"

The backwash, brine, and slow rinse flows should not differ from those in Appendix A, "Table 14. CSM Series Water Soft-

eners - Flow Rate Data (GPM)" on page 92 by more than 15%.

Appendix A, "Table 15. CSM Refill Minutes/Salt Dosage/Capacity"

This table shows the hardness removal capabilities for each unit as a function of salt dosage and refill time. Multiply the

inlet hardness times the maximum daily water usage to determine the daily capacity requirement. If the hardness or water

usage has increased, a higher salt dosage, more frequent regeneration, or a larger softener may be needed.

NOTICE The rate at which brine is drawn from the brine tank should not differ by more than 5%. The refill

rate should be as close as possible to the rate shown in Appendix A, "Table 14. CSM Series Water

Softeners - Flow Rate Data (GPM)" on page 92; high or low pressure installations may require

the substitution of a different refill flow control.

If there are no apparent general problems or environmental problems, refer to "Troubleshooting Guide" on page 60.

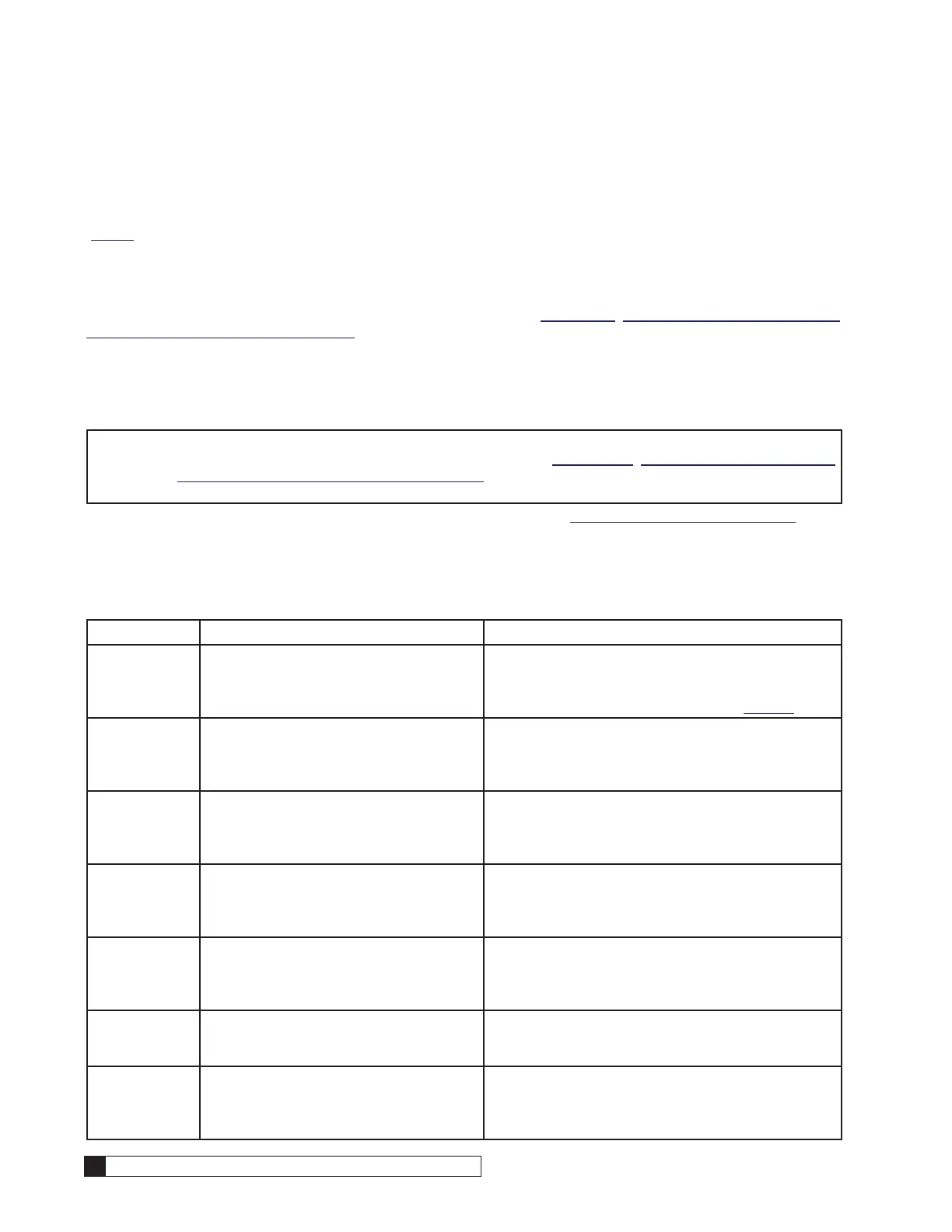

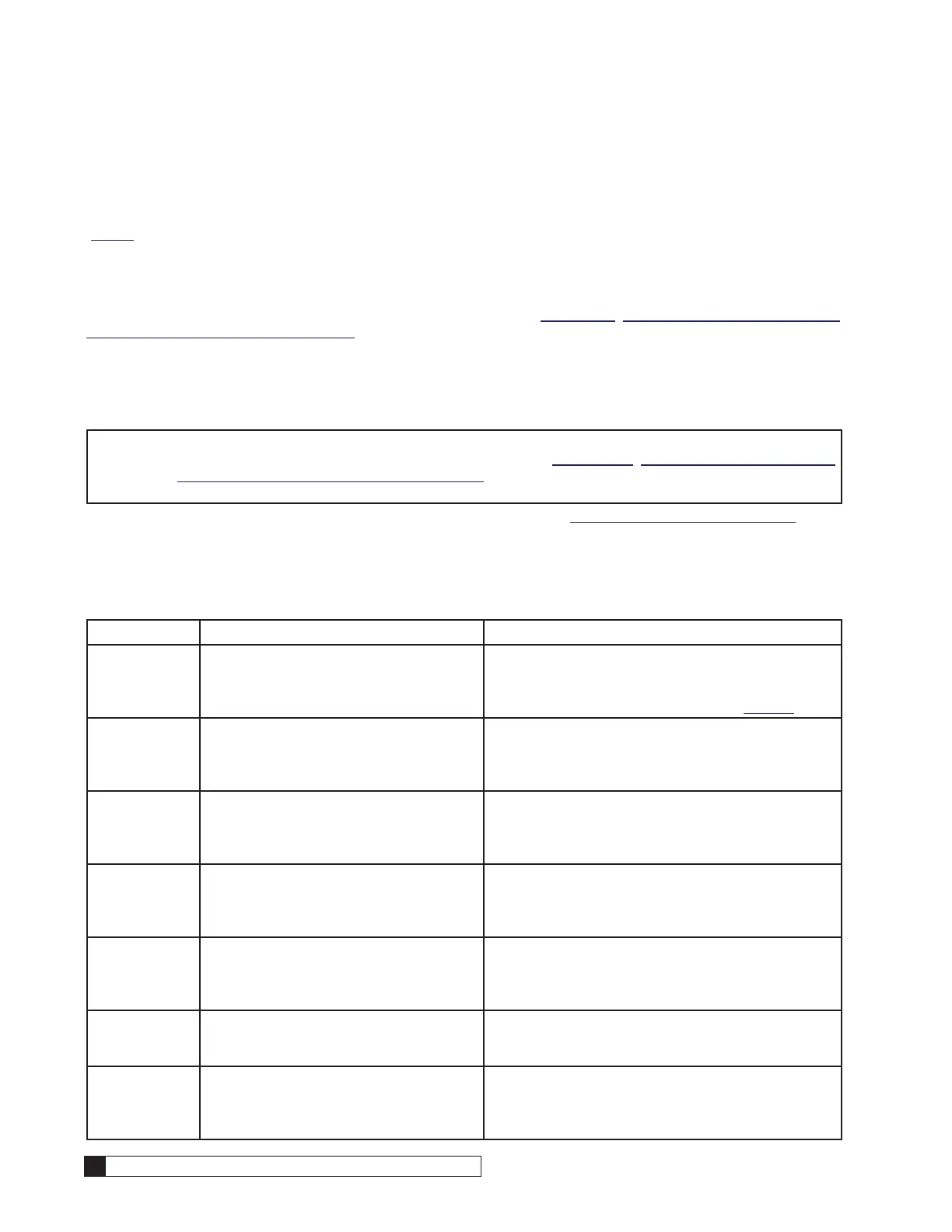

Suggested Preventative Maintenance Inspection Schedule

The Culligan CSM series commercial water softener has been designed to provide a good, consistent service life. Rou-

tinely inspecting the system may help avoid potentially costly breakdowns related to circumstances outside of the control

of the dealer and/or user.

Component Suggested Inspection Frequency Reason for Maintenance

Entire System At Start-up, after infrequent use (idle for

one week or more) or every 3 - 6 months if

on a private water supply.

On private supplies, the appearance of off-tastes and

odors, particularly if musty or “rotten egg” (caused by

harmless sulfate-reducing bacteria) may indicate a

need for the system to be sanitized. See page 57.

Backwash Flow Every 12 months or every time service is

performed on the system.

Build up of sediment, iron and/or other foreign materi-

als (found in some water supplies but not necessarily

all) could negatively affect system performance.Monitor

item for normal (or unexpected) wear

Controller Every 6-12 months or every time service is

performed on the system.

Build up of sediment, iron and/or other foreign materi-

als (found in some water supplies but not necessarily

all) could negatively affect system performance.Monitor

item for normal (or unexpected) wear.

Pilot Valve

Assembly

Every 6-12 months or every time service is

performed on the system.

Build up of sediment, iron and/or other foreign materi-

als (found in some water supplies but not necessarily

all) could negatively affect system performance.Monitor

item for normal (or unexpected) wear.

Brunermatic

Valve

Every 6-12 months or every time service is

performed on the system.

Build up of sediment, iron and/or other foreign materi-

als (found in some water supplies but not necessarily

all) could negatively affect system performance.Monitor

item for normal (or unexpected) wear.

Pilot Strainer Every 6-12 months or every time service is

performed on the system.

Build up of sediment, iron and/or other foreign materials

(found in some water supplies but not necessarily all)

could negatively affect system performance.

Softening

Media

Every 2 - 3 years Chlorinated water supplies can break down/destroy res-

in material. Resin material may also perform poorly if

subjected to other materials (sediment, iron, alum, etc)

found in some water supplies (but not necessarily all).

Final Start-up 58

Loading...

Loading...