INSTALLATION

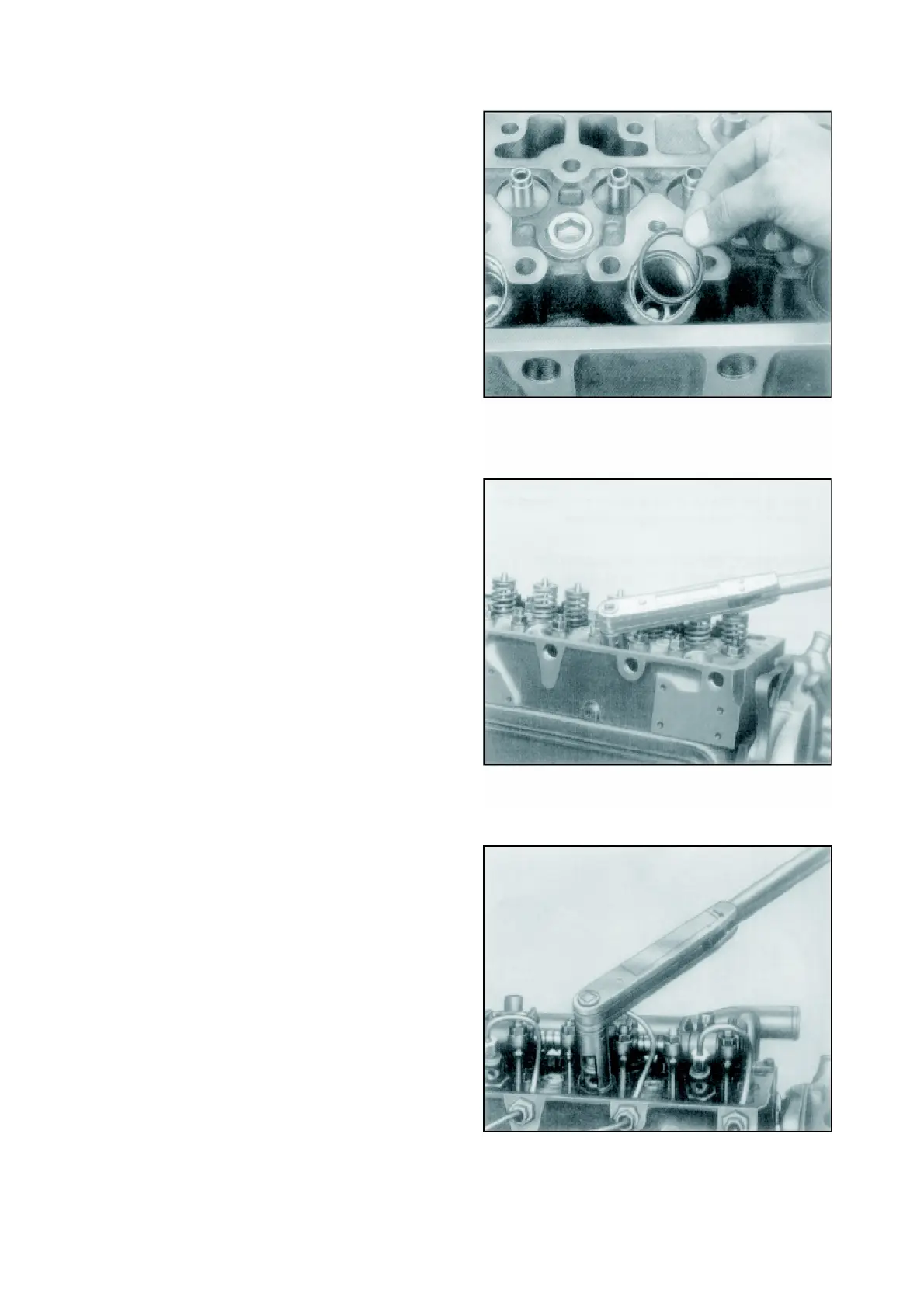

1. Apply a light coat of grease/oil to new

sealing ring and place it in cylinder head.

Fig. 18.

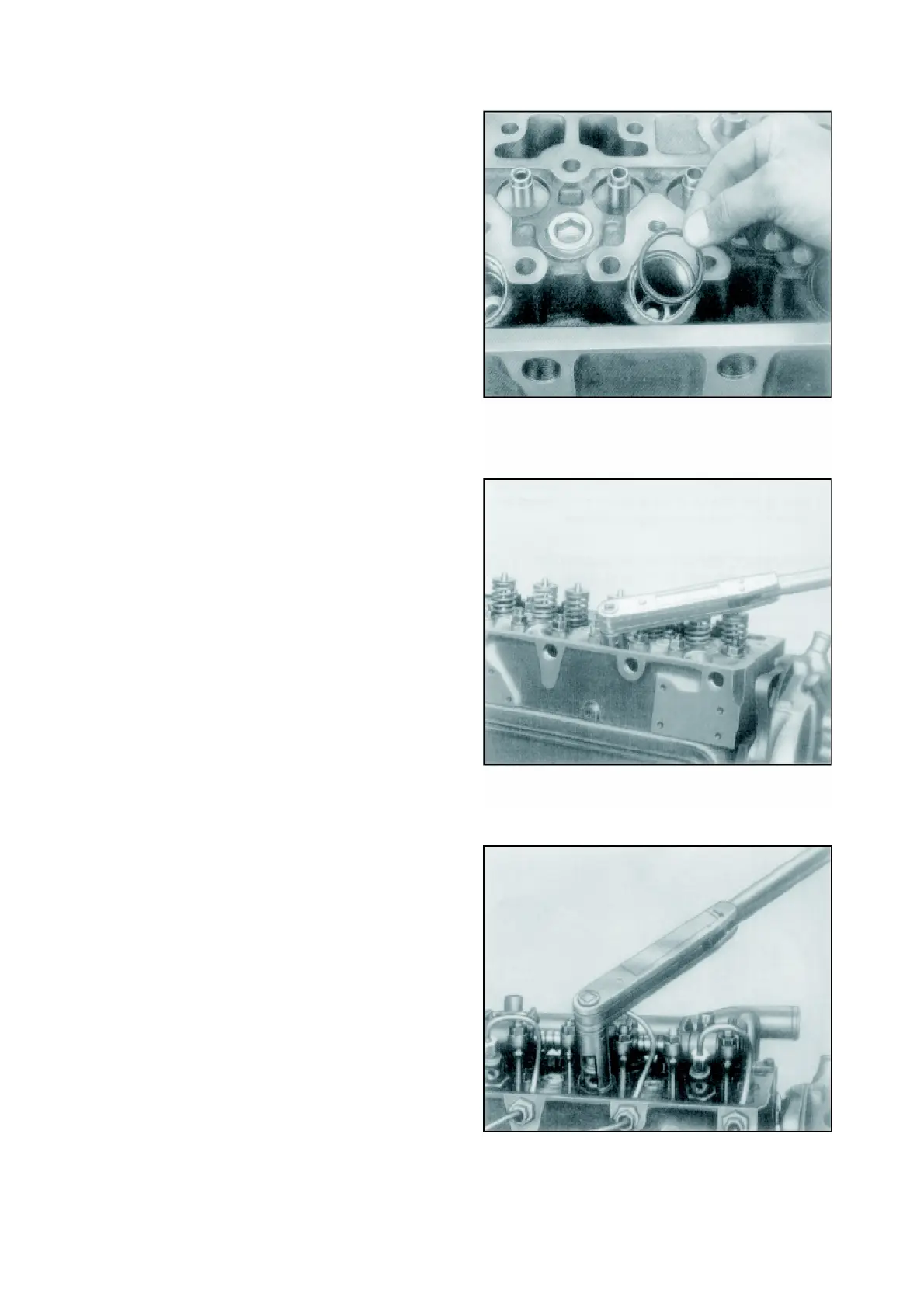

2. Screw in protective sleeve into cylinder head

with adapter, 000 589 0309 and tighten to

specified torque. Fig. 19.

3. Insert new copper washer for the injectors

into protective sleeves.

4. Insert injectors into cylinder head after

aligning the locating lug of the nozzle holder

into slot provided into cylinder head.

5. Screw-in pressure screw for nozzle holder

with socket, 000 589 0209 and tighten to

specified torque. Fig. 20.

6. Install leak off line with new sealing washers

and tighten banjo bolts to specified torque.

7. Connect high pressure line to injectors and

delivery valve holder ensuring the pipes are

free from tension. If necessary align pipes

free of tension with special tool, 312 580

0085. Tighten high pressure lines cap

nuts to specified torque. Fig. 21.

8. Screw-in and tighten inner screw plugs into

cylinder head.

9. Tighten outer screw plug into the inner screw

plug over sealing rings.

10. Fit high pressure line clamps.

11. Install cylinder head covers with gasket.

INSPECTION OF INJECTION NOZZLES

(Injectors removed)

1. CHECKING NOZZLE OPENING PRESSURE

Carefully remove carbon deposits from nozzle.

Connect injector assembly to nozzle tester.

Depress nozzle tester lever down slowly with

pressure gauge connected one stroke per

second and read opening pressure when

nozzle starts opening. If the opening

pressure is too high or too low, disassemble

and clean injection nozzle and adjust as

required by selecting the adjusting shims. (If

the pressure

is too high, use thinner shims, if too low, use

Workshop Manual

S3.8 Engine

A030K288 (Issue 2)

01-2010

Loading...

Loading...