14

Stage 3

Laminating

Laminating

Corners and bandaging

Laya200mmsquarepieceofmatontheroofdeckand‘wetout’onboth

sides with resin (see hardener addition chart) using a 70mm application

roller. Place the mat onto the face of the adjoining trims with the bottom

edge on the radius of the trim. Fold around the corner and fold over the

top of the trim down on to the deck. It will be easier to dress and feather if

the mat is cut vertically from the top corner of the trim upwards. Using the

70mm roller, 50mm laminating brush and small consolidating roller, feather the corners into place. Any joint in the trims should be bandaged

using the same mix of resin. If any boards are not completely engaged these joins should be bandaged, even a small gap may cause resin to

leak through the boards which will lead to porosity in the laminate.

If any nails holding the trims are not going to be covered with laminate on the deck or corners they should be laminated with a small piece of mat.

The deck of the roof can be laminated before the corners and bandages have cured.

Bandaging for all other details can be completed as outlined in the GRP Edge Trim section.

Laying the main laminate

Unroll 1m of previously cut mat along the lowest part of the roof and align so it

can be unrolled across the roof without running off-line. Carefully roll the mat back.

Togetaratioof3:1one-thirdCureItRoongResin(withhardeneradded)shouldbeappliedontheboardandtwothirdsresinandhardener

on the mat dip the 140mm application roller into the bucket of resin. Lift the roller out of the bucket and without letting the excess run off,

drop3rollersfullontotheboardandcoat1squaremetre.Thiswillensurethatthereisaratioofone-thirdresinontheboard.

UnrollthematontotheCureItRoongResincoatedboard.Instripsof140mm(1rollerwidth)wetoutthematbydropping1rollerfullinthe

middleofeach140mmrun,pushtherollerawaytotheendofthe1metrerun,thenpullbackoverthefull1metre(gure4.)

Continueacrossthe1m²(approximately6runs)andthenrolltherolleroverthewholeareaagaintoensuregoodevencoverage.

Wetoutthenext1m²ofboardinthesameway,rememberingtouseonethirdoftheCureItRoongResinontheboardandtwo

thirdsofresinonthemat.Rolloutthematoverthenext1m²ofwetoutboardandcontinuetorollouttheCureItRoongResinas

previously described.

Note:

• Never attempt to lay a roof in wet weather or when wet

weather is forecast.

• If it starts to rain while you are laying a roof, the roof must be

coveredandmustnotgetwet,alwayskeepalargevisqueen

sheetonsitetocovertheroof.Thevisqueenwillnotbondto

the curing laminate

• If rain is forecast while laying boards, the boards can be

temporarily sealed with a coating of resin. Always ensure that

as much of the roof is covered as possible, ensure that edges,

or areas of possible water ingress are covered.

• If decking has become damp, do not attempt to lay laminate

on top.

• Always ensure that the surface you are laying onto is completely

dry and free from debris before you start. A wet surface can lead

to delamination

Note: Avoid spillages by masking off the roof properly,

anesprayiscausedwhenusingtheconsolidatorroller,

wind can carry this a considerable distance. It is important

to ensure that this is considered before the resin is used

on the roof. When resin has cured, there is no easy way

of removing it from car paintwork without damaging the

paintwork. (see spillages in the troubleshooting section.)

YOU MUST FOLLOW THESE INSTRUCTIONS TO

GAIN THE CORRECT RATIO OF RESIN TO GLASS.

Any other protrusions such as pipes, skylights or other

potential weakspots should also be laminated around/over

at this point.

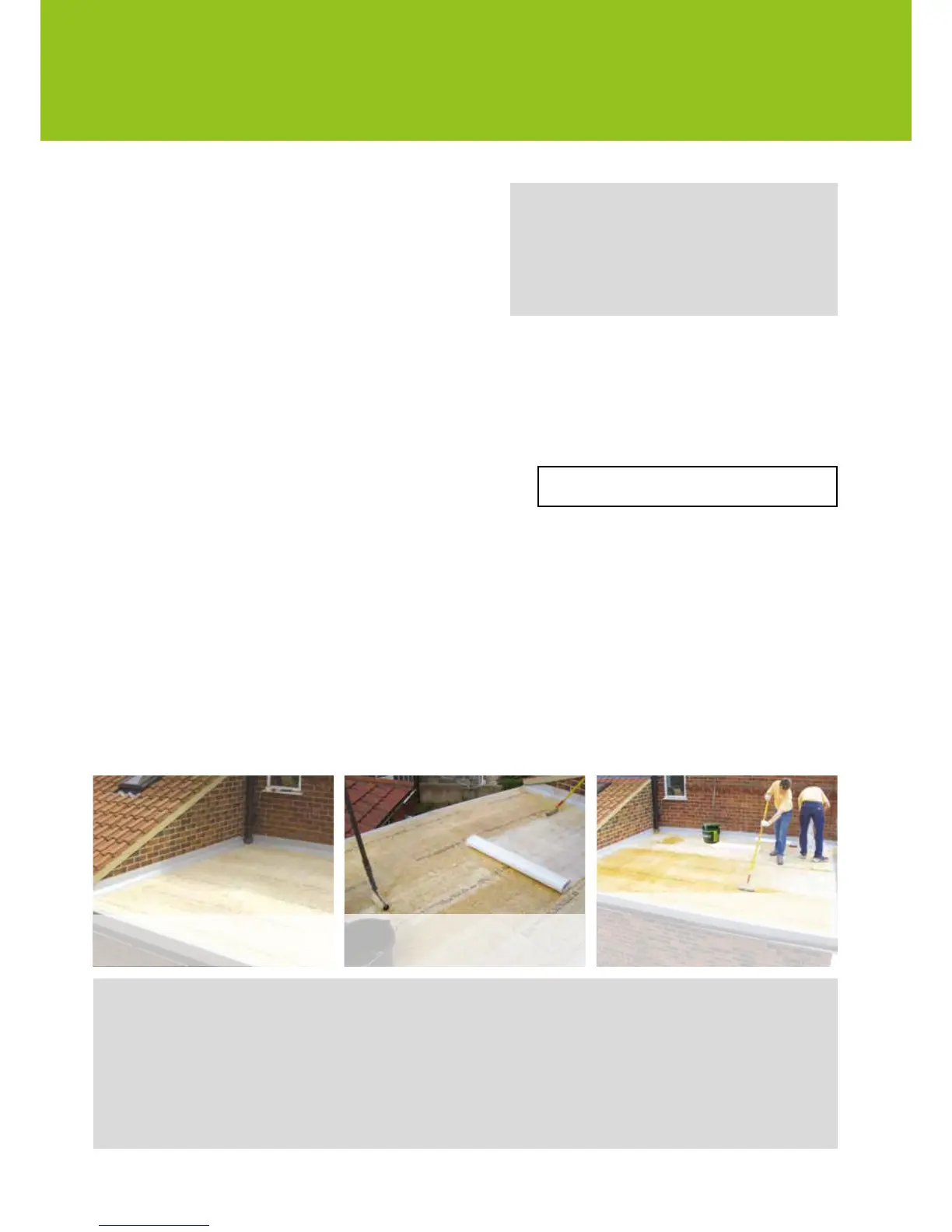

Any joints between trim lengths are bandaged over.

A polyester roller is used to apply the resin to the

Reinforcement Mat.

CureItRoongResinisappliedtothedeckbeforethe

Reinforcement Mat is laid on the roof.

After the Reinforcement Mat has ‘wet out’, the consolidator

roller is used to expel air from the laminate and ensure the

Reinforcement Mat has been saturated by the resin. No

white patches should be visible.

As the Reinforcement Mat absorbs the resin, the laminate

becomes transparent.

Loading...

Loading...