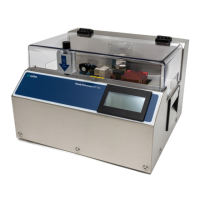

Why is there no gas flow in my cytiva ReadyToProcess WAVE 25 Laboratory Equipment?

- MMichael ThomasAug 20, 2025

If there's no gas flow, fluctuating gas flow, and a high pressure alarm, it could be due to the gas flow shutting down or being restricted by a blockage in the gas tubing or vent filters, or a clogged Cellbag bioreactor outlet vent filter. Ensure all inlet and outlet lines are open. Disconnect the N /Air and Gas mix out 2 tubing and locate any blockage. Also, check that the Filter heater functions properly. If the outlet gas flow is blocked by foam, reduce the rocking angle or decrease the rocking speed. If the problem persists, transfer the contents to another Cellbag bioreactor.