9

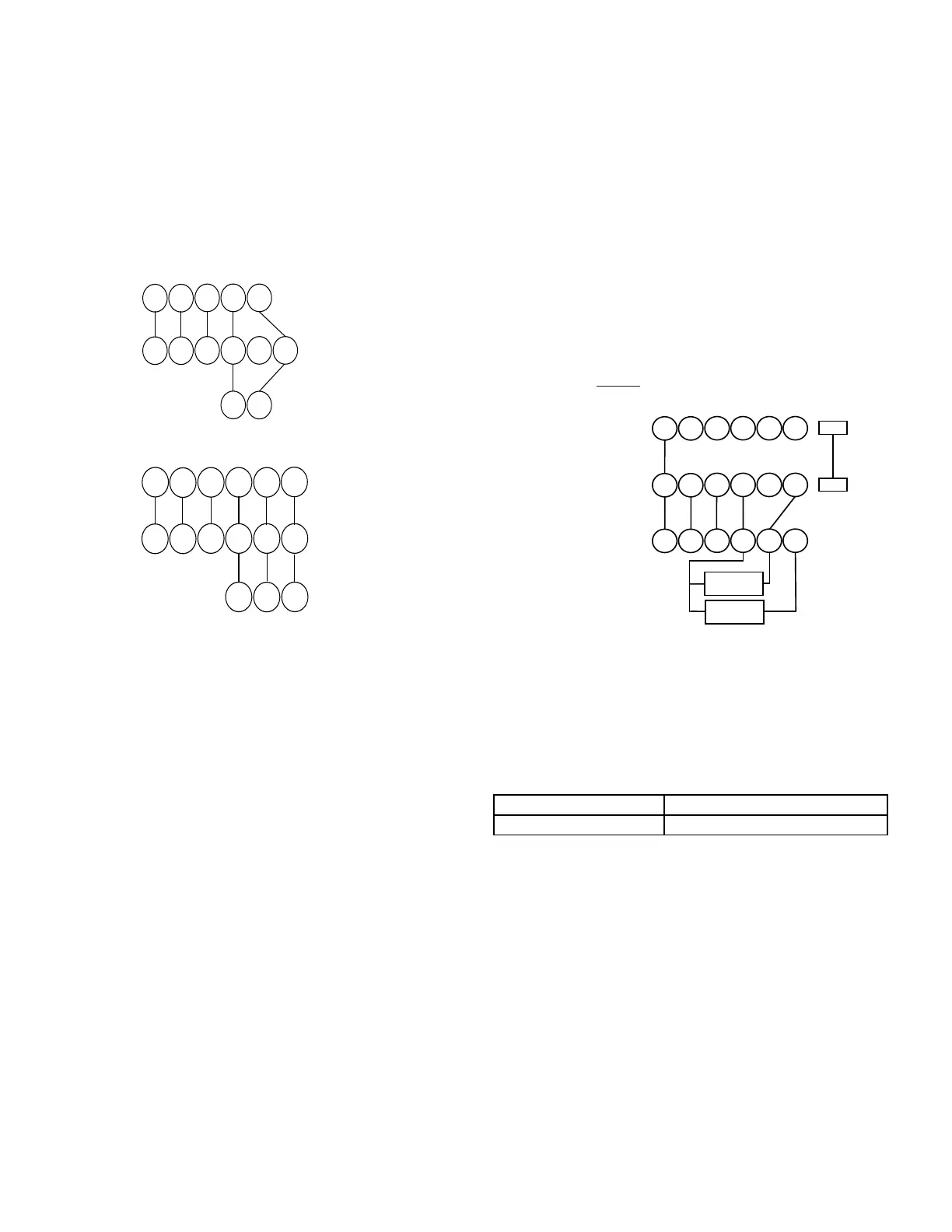

Low voltage connections can be made through either the

right or left side panel. Thermostat wiring entrance holes

are located in the blower compartment. The following gure

shows connections for a “heat/cool system”.

This furnace is equipped with a 40 VA transformer to facili-

tate use with most cooling equipment. Consult the wiring di-

agram, located on the blower compartment door, for further

details of 115 Volt and 24 Volt wiring.

Y

C

Y

C

G

R

W

Y2

Y/Y1

C

G

R

W

ROOM THERMOSTAT

INTEGRATED FURNACE

CONTROL MODULE

REMOTE COOLING UNIT

(SINGLE STAGE)

Y1

C

Y1C

G

R

W

Y2

Y/Y1

C

G

R

W

ROOM THERMOSTAT

INTEGRATED FURNACE

CONTROL MODULE

REMOTE COOLING UNIT

(TWO STAGE)

Y2

Y2

This furnace can be used in conjunction with a heat pump

in a fossil fuel application. A fossil fuel application refers to

a combined gas furnace and heat pump installation which

uses an outdoor temperature sensor to determine the most

cost ecient means of heating (heat pump or gas furnace).

A heat pump thermostat is required to properly use a sin-

gle-stage furnace in conjunction with a heat pump. Refer to

the fossil fuel kit installation instructions for additional ther-

mostat requirements.

Strictly follow the wiring guidelines in the fossil fuel kit in-

stallation instructions. All furnace connections must be made

to the furnace two-stage integrated control module and the

“FURNACE” terminal strip on the fossil fuel control board.

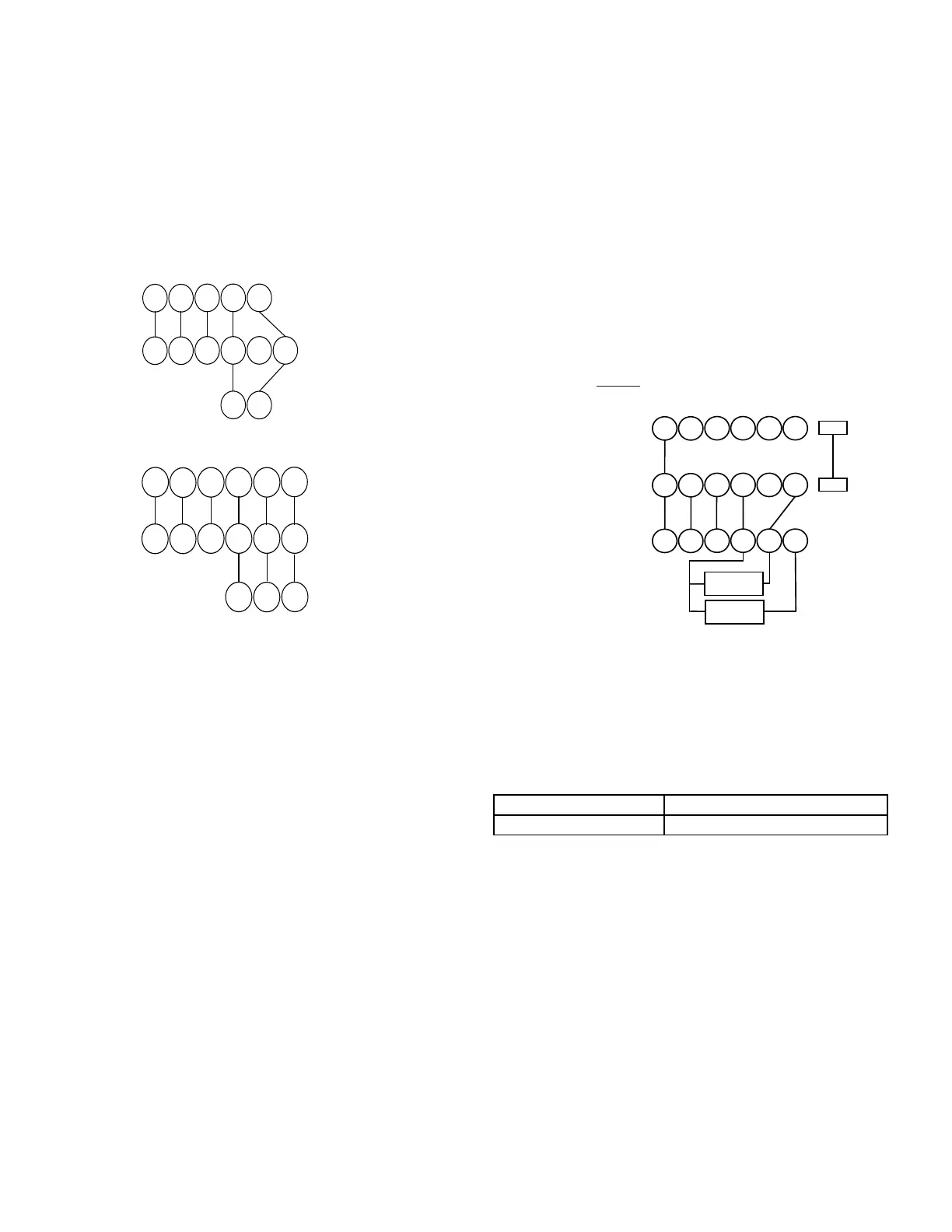

Two furnaces of the same model may be twinned. The in-

tegrated control board has a 3/16” terminal labeled “TWIN”

located beside the low voltage thermostat connection strip.

Twinning allows simultaneous operation of two furnaces and

forces the indoor blower motors of each furnace to oper-

ate synchronously into a common duct system. Using the

twinning function will require only eld installed wiring with

no external kits or parts. The staging and speed tap options

must be set the same on both furnaces.

Each furnace must be connected to it’s own 115 VAC

power supply. The L1 connection to each furnace must be in

phase (connected to circuit breakers on the same 115 VAC

service panel phase leg). To verify that the furnaces are in

phase, check from L1 to L1 on each furnace with a voltme-

ter. If the furnaces are in phase, the voltage between both

furnaces will be ZERO.

ROOM THERMOSTAT

Y2

Y/Y1

C

G

R

W

Y2

Y/Y1

C

G

R

W

Y2

Y/Y1

C

G

R

W

TWIN

TWIN

COND UNIT

CONTACTOR

COND UNIT

CONTACTOR

FURNACE 1

FURNACE 2

-

The furnace integrated control module is equipped with line

voltage accessory terminals for controlling power to an op-

tional eld-supplied humidier and/or electronic air cleaner.

The accessory load specications are noted in the chart:

1.0 Amp maximum at 120 VAC

1.0 Amp maximum at 120 VAC

Turn OFF power to the furnace before installing any acces-

sories. Follow the humidier or air cleaner manufacturers’ in-

structions for locating, mounting, grounding, and controlling

these accessories. Accessory wiring connections are to be

made through the 1/4” quick connect terminals provided on

the furnace integrated control module. The humidier and

electronic air cleaner hot terminals are identied as HUM H

and EAC H. The humidier and electronic air cleaner neutral

terminals are identied as NEUTRAL. All eld wiring must

conform to applicable codes. Connections should be made

as shown.

Loading...

Loading...