ESIE17-19C | Part 2. Troubleshooting 2.2. Error based troubleshooting

19/08/19 | Version 1.1 Page 29

Optimized Heating 4

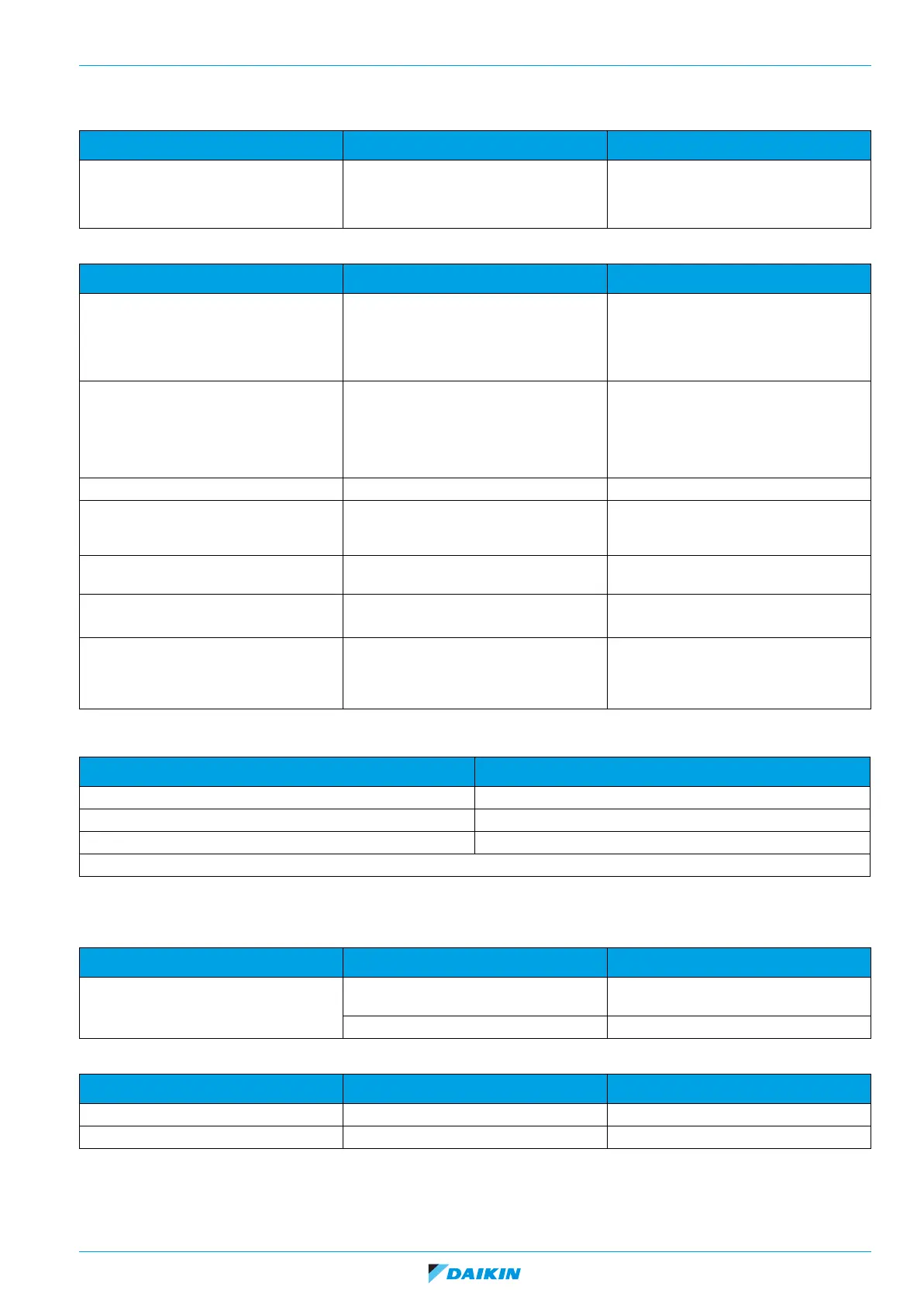

2.2.2.7. “E9-00” – Electronic expansion valve abnormality (units with no pressure sensor)

More info:

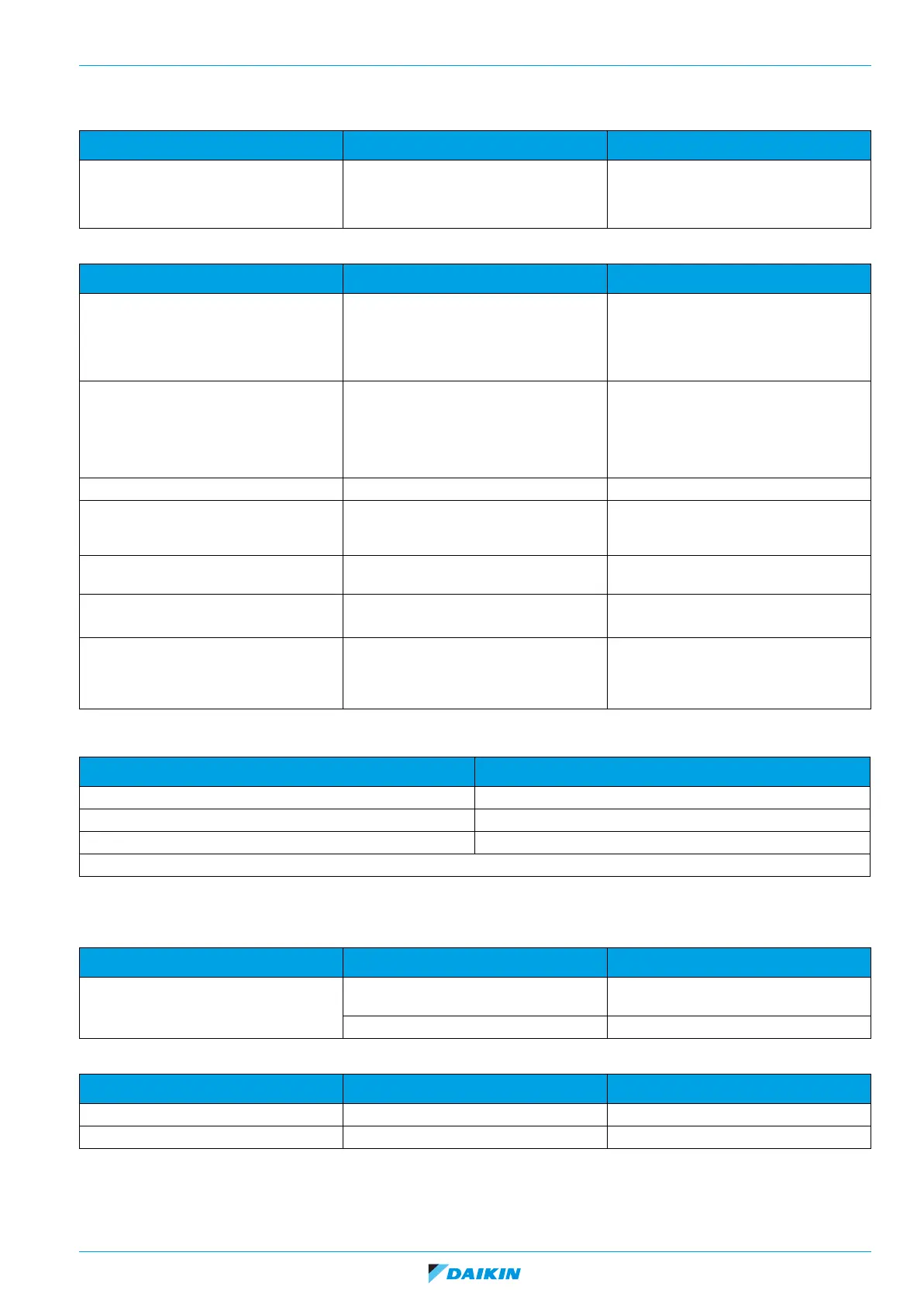

2.2.2.8. “EA-00” – 4-way valve abnormality

Trigger Effect Reset

1. No continuity of expansion valve.

2. Minimum expansion valve opening

and suction superheat < A K and

discharge superheat < B K.

Unit will stop operating. Manual reset via user interface.

Power reset via outdoor unit.

Possible cause Check Corrective action

Wet operation. Check for wet operation. (Wet operation

can be detected by checking the suction

superheat. If the suction superheat is 0°C

then liquid refrigerant is returned to the

compressor.)

In case wet operation was detected, con-

firm the cause:

• Refrigerant overcharge.

• Faulty expansion valve.

Faulty outdoor unit main PCB. Check if the HAP LED is blinking in regu-

lar intervals.

Check if the correct spare part is installed.

Check if the outdoor main PCB receives

power.

Adjust the power to the outdoor main

PCB.

Replace outdoor main PCB when HAP

LED is not blinking in regular intervals.

Faulty thermistor. Check thermistor. Replace thermistor when required.

Faulty or disturbance of the power supply

(imbalance >10%). Power drop. Short cir-

cuit.

Check if the power supply is conform with

regulations. No fluctuations in frequency.

Adjust power supply when required.

Power reset via outdoor unit.

Faulty expansion valve. Check the expansion valve. Replace the expansion valve body or

motor when required.

Faulty capacity adapter on outdoor PCB. Check if the correct adapter is installed.

Check if the correct spare part is installed.

Adjust capacity adapter when required.

External factory (e.g. electrical noise)

(cause when error is reset after power

reset, and error happens again after a

while).

Check for source which could cause elec-

trical interference.

Avoid electrical interference.

Check procedures Replacing procedures

"Main PCB" on page 56 "Replacing main PCB" on page 95

"Refrigerant thermistors" on page 60

"Electronic expansion valve" on page 53 "Replacing expansion valve body" on page 89

"Product specific information" on page 118

Trigger Effect Reset

The room thermistor / indoor heat

exchanger are not functioning within oper-

ation range.

Unit will not stop operating. Automatic reset when unit runs without

error for 60 minutes.

Unit will stop operating. Manual reset via user interface.

Possible cause Check Corrective action

Faulty 4-way valve coil. Check 4-way valve coil. Replace 4-way valve coil when required.

Faulty 4-way valve body, blocked. Check 4-way valve body. Replace 4-way valve body when required.

Loading...

Loading...