Mamac Panel-Mounted Pressure Transducer

WARNING

Electric shock hazard. Can cause personal injury or equipment

damage.

This equipment must be properly grounded. Connections and

service to the MicroTech III control panel must be performed

only by personnel that are knowledgeable in the operation of

the equipment being controlled.

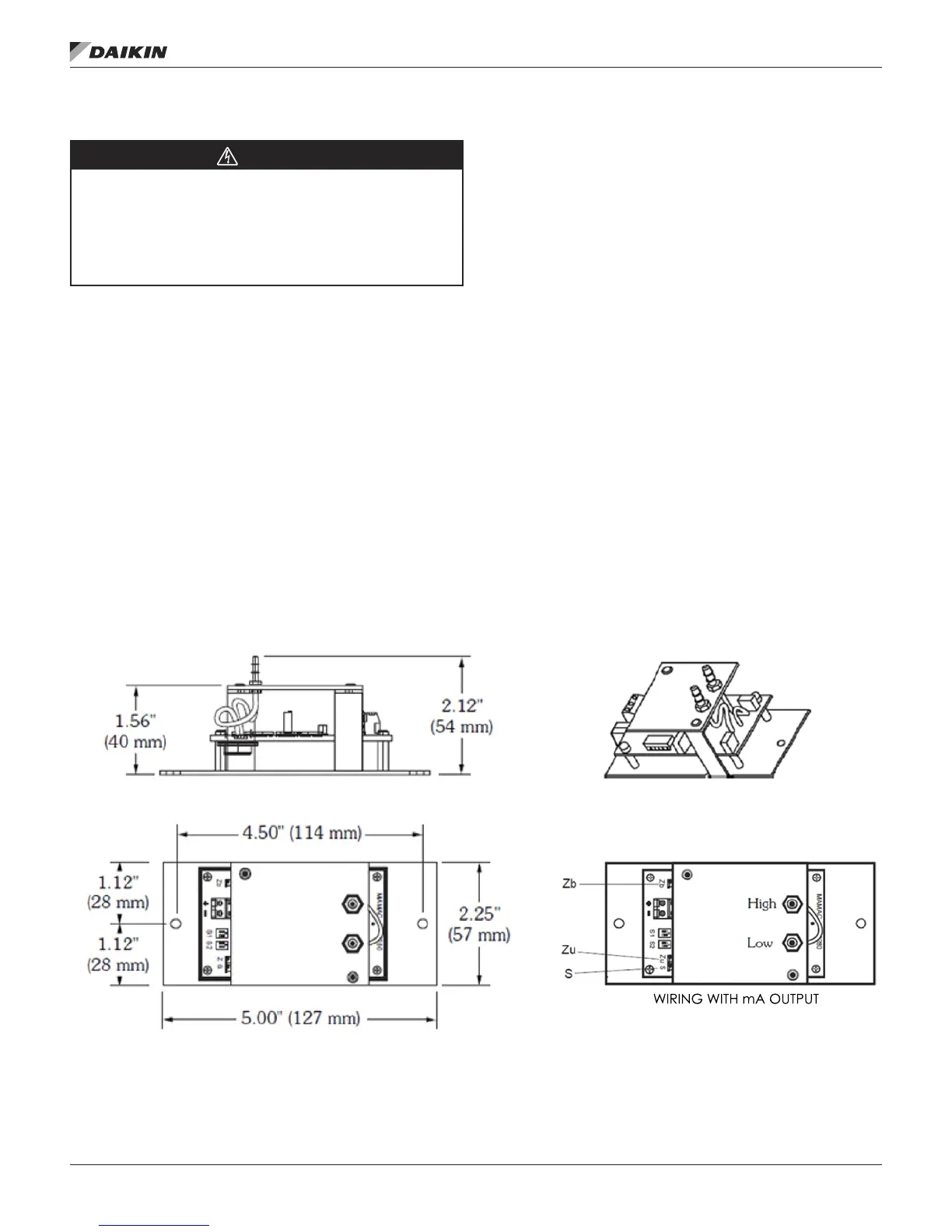

The following describes the proper wiring of these pressure

transducers with mA output.

1. Remove the terminal block by carefully pulling it off the

circuit board.

2. Locate the [+] and [-] terminal markings on the board.

3. Attach the supply voltage to the [+] lead.

4. Connect the 4-mA output ([-] terminal) to the controller’s

input terminal.

5. Ensure that the power supply common is attached to the

common bus of the controller.

6. Re-insert the terminal block to the circuit board and apply

power to the unit.

7. Check for the appropriate output signal using a DVM set

on DC milliamps connected in series with the [-] terminal.

Specications

Accuracy: ± 1% FS

Overpressure: 10 PSID

Supply Voltage: 12–40 VDC

12–35 VAC (VDC output units only)

Supply Current: VDC units — 10mA max.

mA units — 20 mA max.

Enclosure: 18 Ga. C R Steel NEMA 4 (P-65) or panel-mount

chassis

Finish: Baked-on enamel PMS2GR88B

Compensated Temp Control: 25°F – 175°F (-18°C – -80°C)

T.C. Error: ± 0.0125%/°F (± 0.02%/°C)

Operating Temp Range: 0°F – 175°F (-18°C – 80°C)

Media Compatibility: Clean dry air or any inert gas

Environmental: 10 – 90% RH Non-condensing

Wire Size: 12 Ga. max.

Load Impedance: 1.6K ohms max. at 40VDC (mA output units)

1K ohms min. VDC output units)

Weight: Enclosure — 1.0 lbs. (45 kg)

Panel-mount — 0.5 lbs. (25 kg)

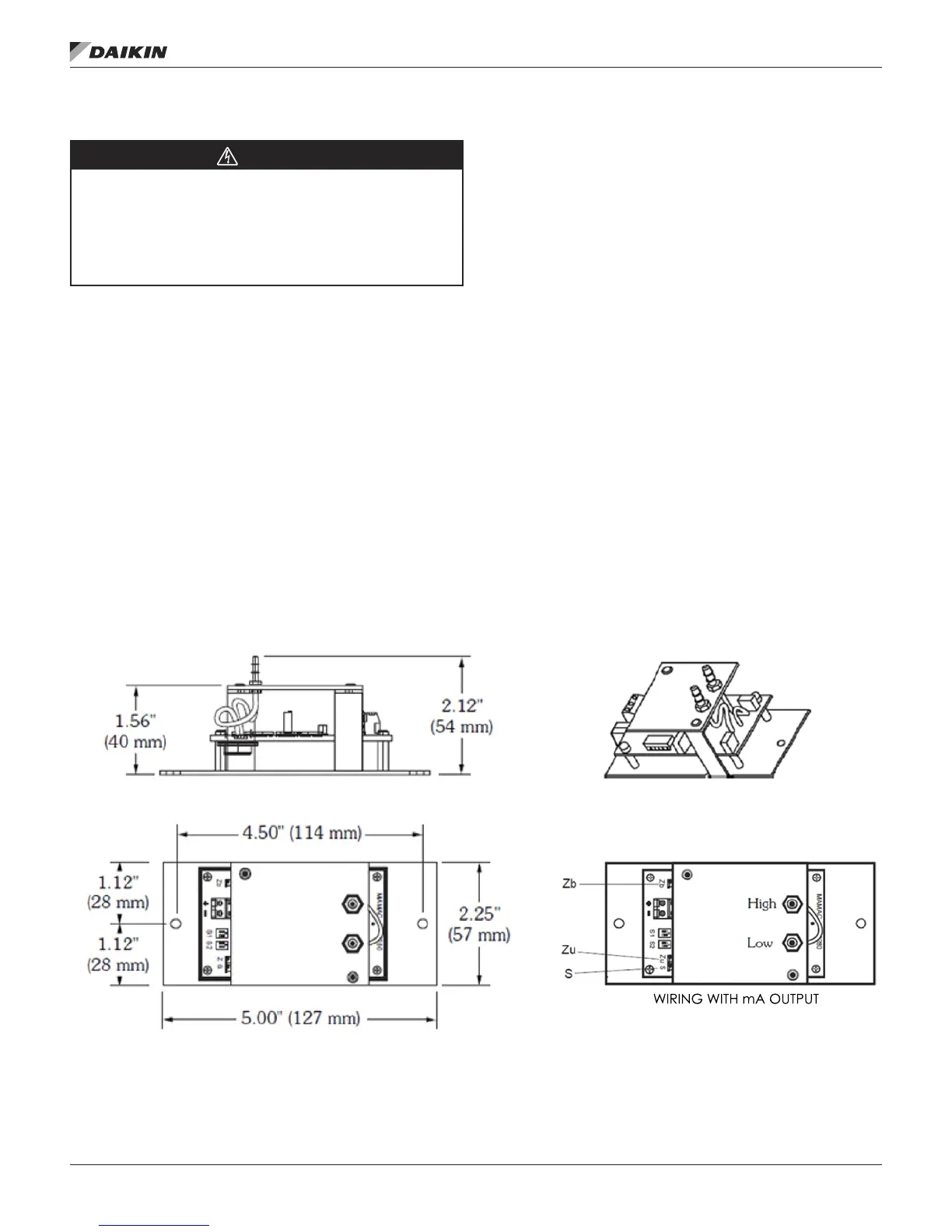

Figure 14: Mamac Panel-Mounted Pressure Transducer Dimensions

IM 919-3 • MICROTECH III CONTROLLER 12 www.DaikinApplied.com

desCrIpTIon of operaTIon

Loading...

Loading...