25

IC.PS.600.A4.02 / 520B2809

© Danfoss A/S (IA-MC/mhe) 05-2007 / 520B2809IC.PS.600.A4.02 / 520B2809

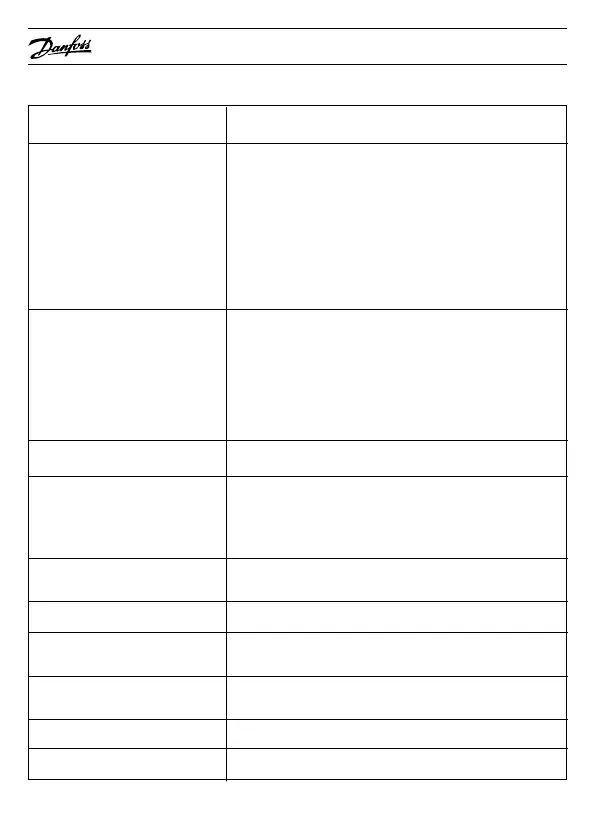

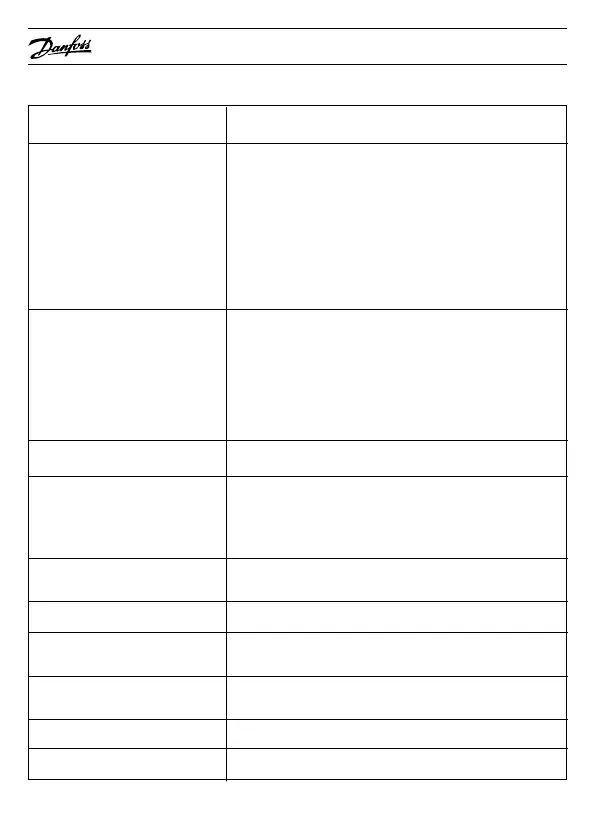

Fault location

Probable cause Remedy

No voltage on coil Check whether valve is de-energised open or closed (NO

or NC):

1. Use a magnetic detector

2. Lift coil slightly and note whether it oers resistance

against lifting

Note: Never remove a coil with voltage applied - it may

burn out.

Check relay contacts. Check lead connections. Check

fuses.

Check to make sure the coil's electrical requirements are

the same as the installation supply. Measure the opera-

ting voltage at the coil. Permissible voltage variation:

±10% for dual frequency; dc and NO applications

+10% / -15% for ac on single frequency voltages

If necessary, replace coil with correct version.

Incorrect voltage/frequency

See page 29Coil burnt out

Check coil data. If necessary, replace coil with correct

version.

Reduce dierential pressure, e.g. by limiting inlet pres-

sure.

Di. pressure too high

Check coil data and dierential pressure. If necessary,

replace coil with correct version.

Di. pressure too low

Replace valve

Dirt at diaphragm

2)

Clean diaphragm. If necessary, replace defective

component(s)

1)

.

Dirt in valve seat/dirt in arma-

ture/armature tube

2)

Clean valve; if necessary, replace defective component(s).

Corrosion Replace defective component(s)

1)

Components missing after

valve dismantling

Fit missing component(s)

1)

.

Damaged/bent armature tube

Symptom: Solenoid valve does not open

Loading...

Loading...