Application guidelines

20 FRCC.PC.002.A4.22

System design recommendations

Suction accumulator

Liquid line solenoid valve

& pump-down

Crankcase heater

A suction accumulator oers considerable

protection against refrigerant oodback both at

start-up and during operation or after the defrost

operation. This device also helps protect against

o-cycle migration by providing additional

internal free volume to the low pressure side of

the system.

The suction accumulator must be selected in

accordance with the accumulator manufacturer

recommendations. As a general rule, Danfoss

Commercial Compressors recommends to size

the accumulator for at least 50% of the total

system charge. Tests however must be conducted

to determine the optimal size.

In refrigeration applications, the Liquid Line Sole-

noid Valve (LLSV) is highly recommended. During

the o-cycle, the LLSV isolates the liquid charge

in the condensor side, thus preventing refriger-

ant transfer or excessive migration of refrigerant

into the compressor. Furthermore, when using

LLSV in conjunction with the pump-down cycle

(especially in low-temperature applications), the

quantity of refrigerant in the low-pressure side of

the system will be reduced.

A pump-down cycle design is required when

evaporators are tted with electric defrost

heaters.

A crankcase heater protects against the o-cycle

migration of refrigerant and proves eective if

oil temperature is maintained 18°F above the

saturated LP temperature of the refrigerant. Tests

must thereby be conducted to ensure that the

appropriate oil temperature is maintained under

all ambient conditions. A PTC crankcase heater is

required with all Maneurop®‚ NTZ compressors.

PTC crankcase heaters are self-regulating.

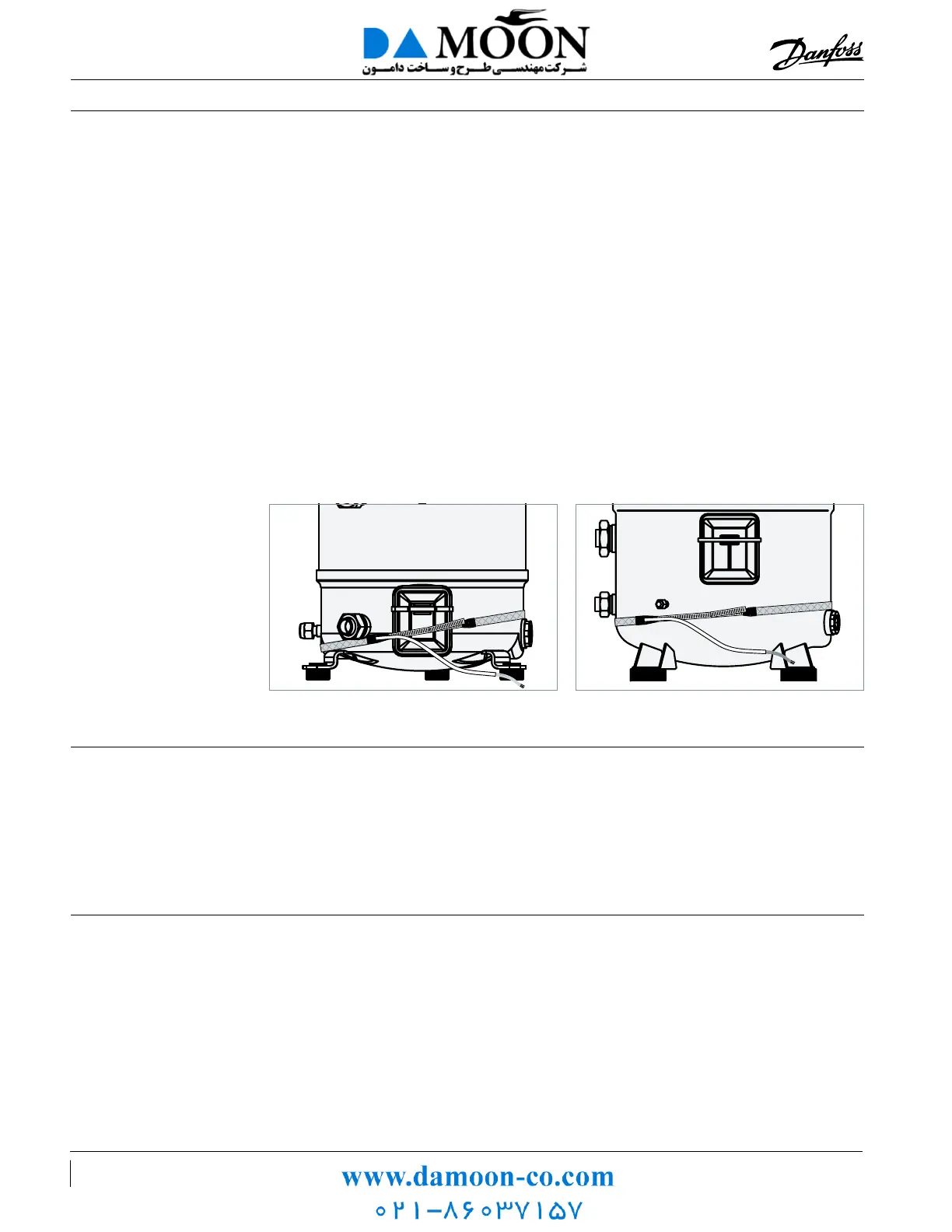

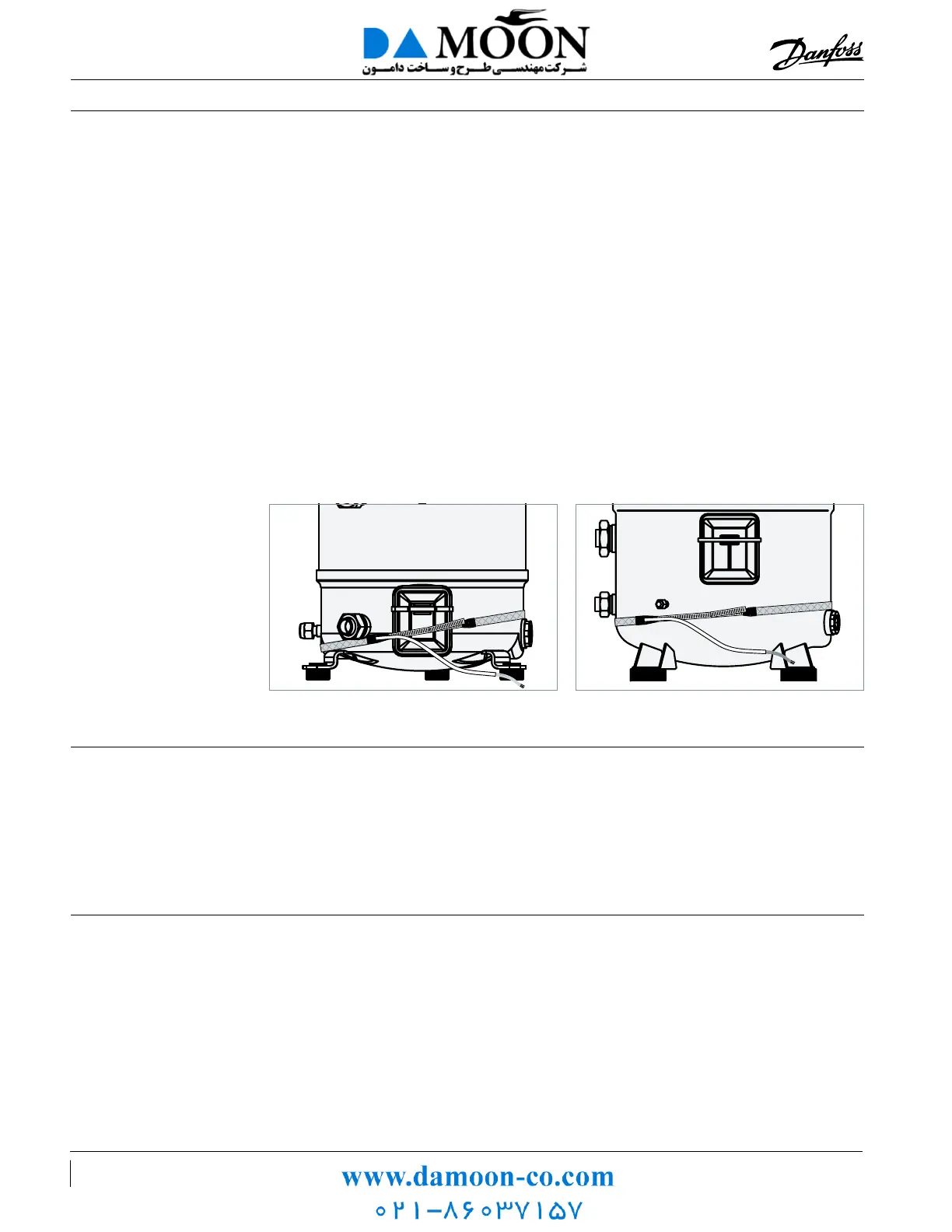

Under extreme conditions such as low ambient

temperature at 5°F or lower a belt type crankcase

heater could be used in addition to the PTC heat-

er, although this is not a preferred solution for 1

and 2 cylinder compressors. The belt crankcase

heater must be positioned on the compressor

shell as close as possible to the oil sump to

ensure good heat transfer to the oil. The below il-

lustrated mounting positions are recommended:

Belt crankcase heaters are not self-regulating.

Control must be applied to energise the belt

heater once the compressor has been stopped

and then to de-energise it while the compressor

is running. The belt heater must be energised

12hours before restarting the compressor follow-

ing an extended down period.

If the crankcase heater is not able to maintain the

oil temperature at 18°F above the saturated LP

temperature of the refrigerant during o cycles

or if repetitive oodback is present a the Liquid

Line Solenoid Valve (LLSV) + pump-down cycle is

required, possibly in conjunction with a suction

accumulator.

Models: NTZ048 - NTZ068 - NTZ096 - NTZ108 - NTZ136 Models: NTZ215 - NTZ271

Loading...

Loading...