Maneurop® NTZ compressors have

been designed and quali ed for sta-

tionary equipment using standard al-

ternating power supply. Danfoss does

not warrant the compressors for use

on mobile applications such as trucks,

railways, subways, ships etc.

These selection and application guide-

lines concern single compressors

only. For guidelines on manifolding

Maneurop® NTZ compressors, please

refer to literature called "Parallel Appli-

cation Guidelines".

16

SYSTEM DESIGN RECOMMENDATIONS

Piping design Oil in a refrigeration circuit is required

to lubricate moving parts in the com-

pressor. During normal system opera-

tion small oil quantities will continu-

ously leave the compressor, with the

discharge gas. Therefore, the system

piping shall be designed in a way

which allows a good oil circulation,

avoiding oil being trapped in the

system and ensuring a constant oil

return to the compressor. As long as

the amount of oil circulating through

the system is small it will contribute to

good system operation and improved

heat transfer e ciency.

Lubricant getting trapped in the

evaporator or suction lines will a ect

system performance and will ulti-

mately lead to compressor lubrication

failures. Where a poor oil return situ-

ation exists, adding lubricant will not

help safeguard the compressor. Only

a correct piping design can ensure

adequate oil circulation maintaining

safe oil level in the compressor.

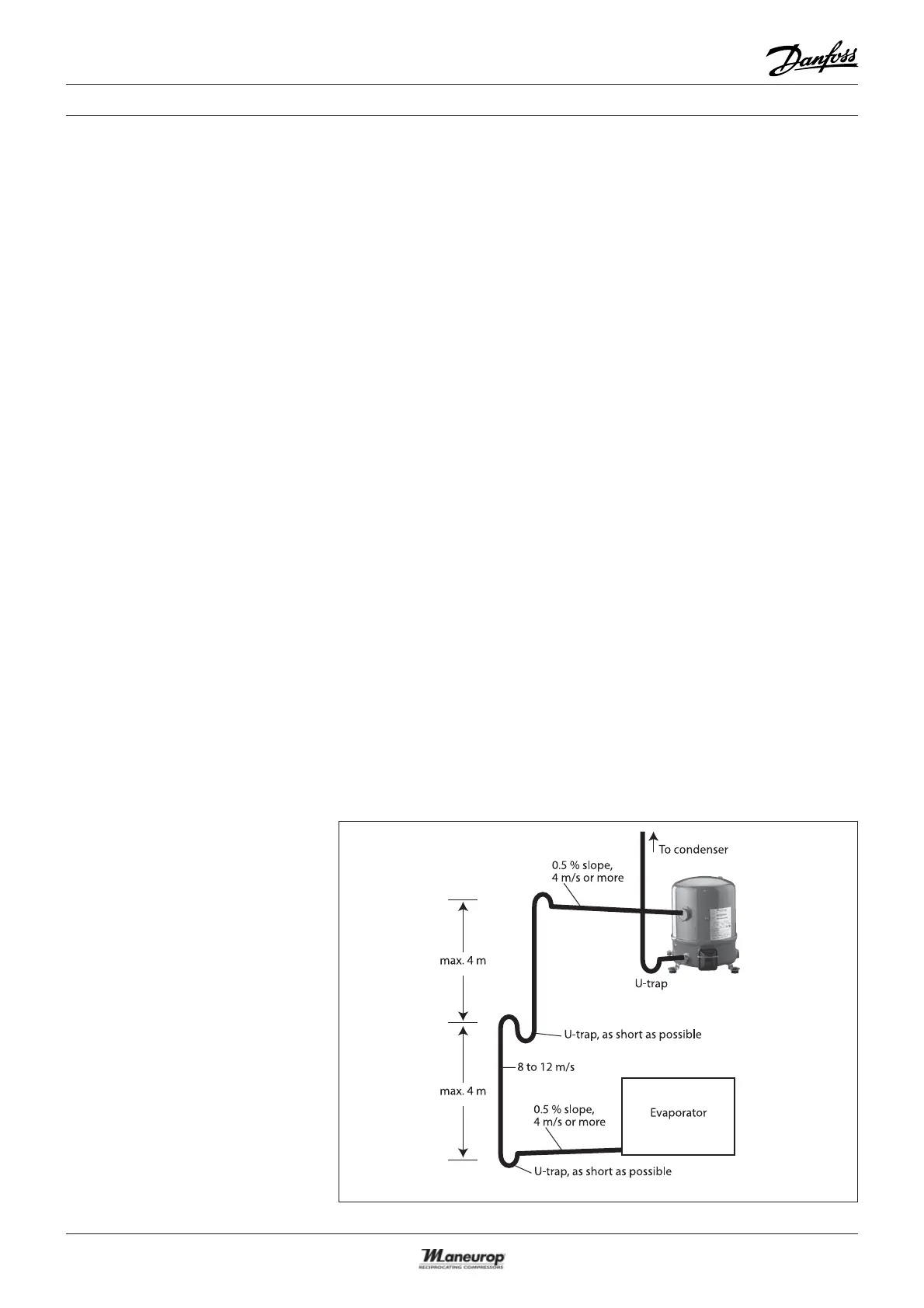

Suction line Horizontal suction line sections shall

have a slope of 0.5% in the direction

of refrigerant ow (5 mm per meter).

The cross-section of horizontal suction

lines shall be such that the resulting

gas velocity is at least 4 m/s. In vertical

risers, a gas velocity of 8 to 12 m/s is

required to ensure proper oil return.

A U-trap is required at the foot of each

vertical riser. If the riser is higher than

4 m, additional U-traps are required for

each additional 4 meters.The length of

each U-trap must be as short as pos-

sible to avoid the accumulation of

excessive quantities of oil (see gure

below).

Loading...

Loading...