Specifications (MC50-155/15B) (continued)

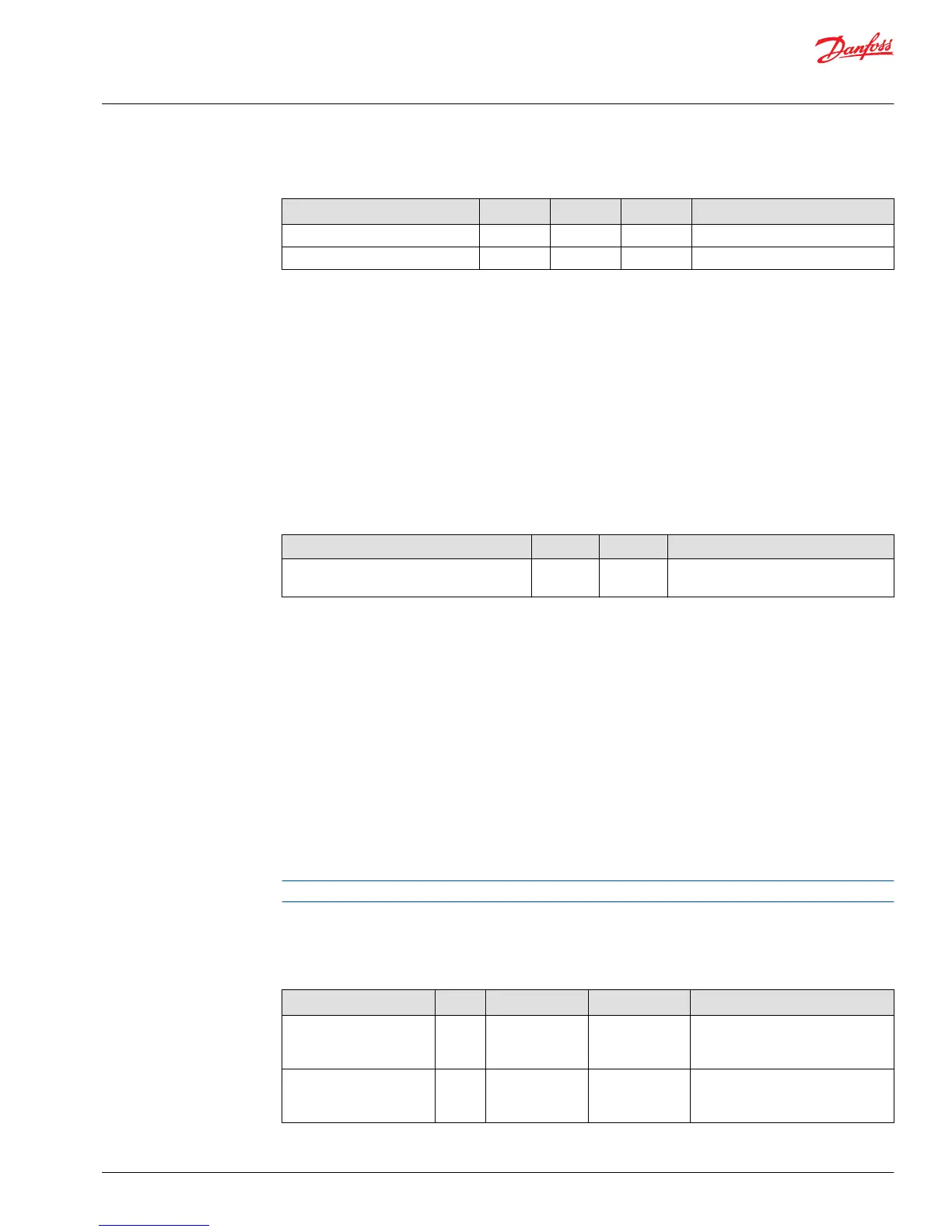

Description Units Minimum Maximum Comment

Output voltage, DIN diagnostics V 1.58 1.71 Nominal 1.6

Output voltage, DIN diagnostics V 3.16 3.39 Nominal 3.3

PVG valve power supply ratings

DOUT/PVGpwr pins can provide the battery supply voltage required by Danfoss PVG valve electronics for

those control strategies requiring application software control of the valve power source.

When enabled, the DOUT/PVGpwr pin passes battery (reference) voltage to the PVG valve electronics.

One DOUT/PVGpwr pin can power up to 3 PVG valves. Refer to individual module API documents for PVG

power pin characteristics.

Non-volatile memory read/write ratings

FRAM memory

Write/erase cycles

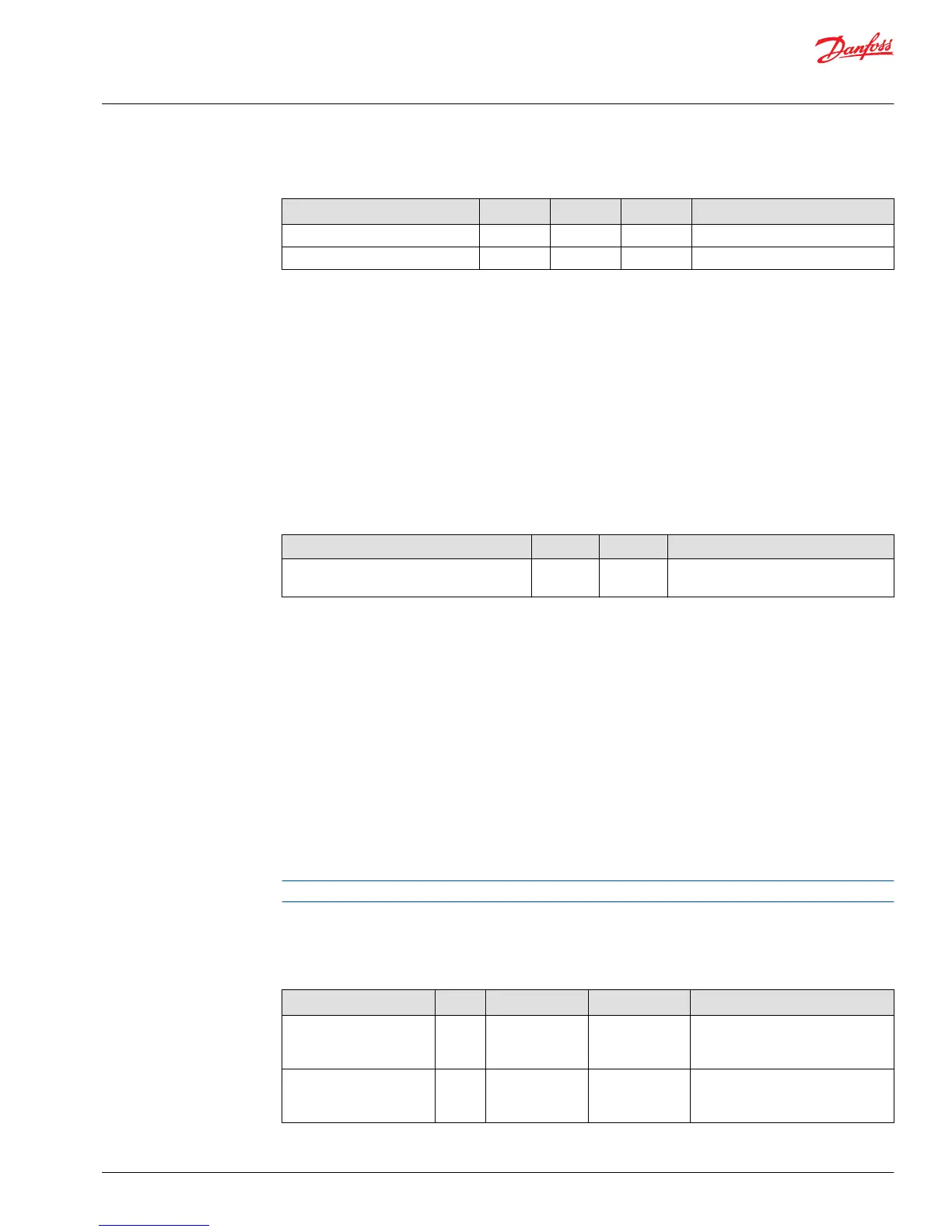

Description Minimum Maximum Comment

FRAM write/erase cycles 100 trillion

Minimum valid over entire operating

temperature range.

FRAM used in the MC0XX-1XX controller, is rated for 100 trillion read/write cycles per sector. Sector size is

32 bits. When a value is written to FRAM, all 32 bits in a particular sector are always written, regardless of

the size of the saved value. If the value being saved in a sector is less than 32 bits (such as. U8, S16, BOOL,

etc) adjacent bits in the same FRAM sector are rewritten with their previous value. The implication of this

memory property is that if two values are being written to the same memory sector, the useful life of the

sector is determined by the value being written most frequently. If that value exceeds 100 trillion read/

write cycles, all values in the sector may be compromised if the useful life is exceeded.

Vault memory

Some variants of PLUS+1

®

modules have 2 Mbyte of serial flash vault memory (also referred to as

application logging memory).

Application developers can use this memory to log machine event data and use the PLUS+1

®

Service Tool

to extract the logged data. As there is no real time clock on PLUS+1

®

modules, vault memory is not time

stamped.

Accessing non-volatile or application log memory can delay the service tool scan.

General ratings

MC controllers general ratings

Description Units Minimum Maximum

Comment

Operating temperature ˚C [˚F] -40 [-40] 70 [158] Maximum operating temperature for

MC012-026/029 modules is 105° C

(221° F).

Storage temperature ˚C [˚F] -40 [-40] 85 [185] Maximum storage temperature for

MC012-026/029 modules is 105° C

(221° F).

Technical Information

PLUS+1® MC0XX-1XX Controller Family

Product ratings

©

Danfoss | April 2018 L1321895 | BC00000227en-US0401 | 21

Loading...

Loading...