VLT

®

8000 AQUA

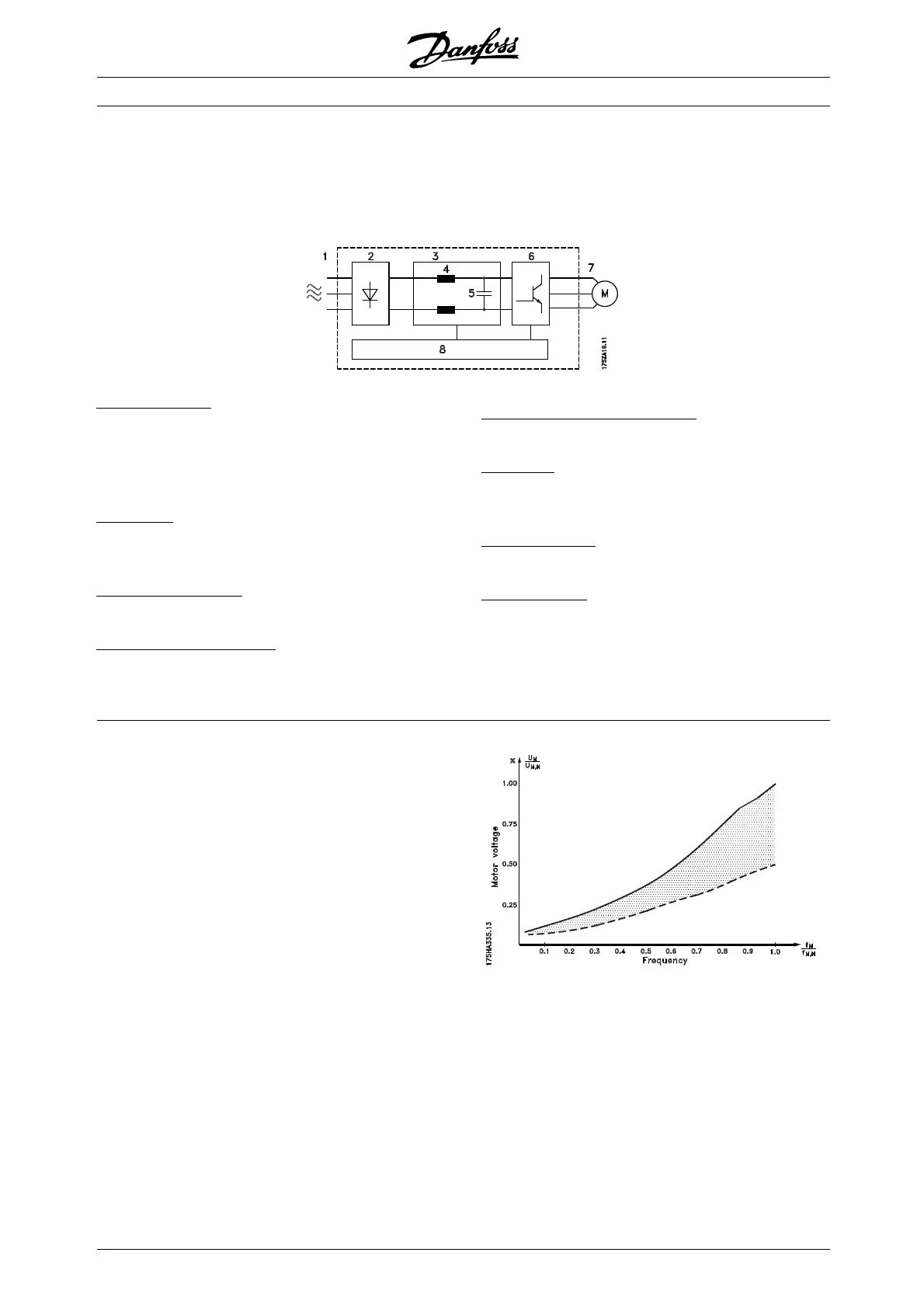

■ Control principle

A frequency converter rectifies AC voltage from

mains into DC voltage, after which this DC

voltage is converted into a AC current with a

variable amplitude and frequency.

The motor is thus supplied with variable voltage and

frequency, which enables infinitely variable speed

control of three-phased, standard AC motors.

1. Mains voltage

3 x 200 - 240 V AC, 50 / 60 Hz.

3 x 380 - 480 V AC, 50 / 60 Hz.

3 x 525 - 600 V AC, 50 / 60 Hz.

3 x 525 - 690 V AC, 50 / 60 Hz.

2

. Rectifier

A three-phase rectifier bridge that rectifies AC

current into DC current.

3

. Intermediate circuit

DC voltage = 1.35 x mains voltage [V].

4

. Intermediate circuit coils

Even out the intermediate circuit voltage

and reduce

the harmonic current feedback to the mains supply.

5

. Intermediate circuit capacitors

Even out the intermediate circuit voltage.

6

. Inverter

Converts DC voltage into variable AC voltage

withavariablefrequency.

7

. Motor voltage

Variable AC voltage, 0-100% of mains supply voltage.

8

. Control card

This is where to find the computer that controls

the inverter which generates the pulse pattern by

which the DC voltage is converted into variable

AC voltage with a variable frequency.

■ AEO - Automatic Energy Optimization

Normally, the U/f characteristics have to be set on the

basis of the expec

ted load at different frequencies.

However, knowing the load at a given frequency in an

installation is often a problem. This problem can be

solved by usin

g a VLT 8000 AQUA with its integral

Automatic Energy Optimization (AEO), which ensures

optimum energy utilization. All VLT 8000 AQUA units

feature thi

s function as a factory setting, i.e. it is

not necessary to adjust the frequency converter U/f

ratio in order to obtain maximum energy savings.

In other

frequency converters, the given load and

voltage/frequency ratio (U/f) must be assessed to carry

out correct setting of the frequency converter.

Using A

utomatic Energy Optimization (AEO), you

no longer need to calculate or assess the system

characteristics of the installation, since Danfoss VLT

800

0 AQUA units guarantee optimum, load-dependent

energy consumption by the motor at all times.

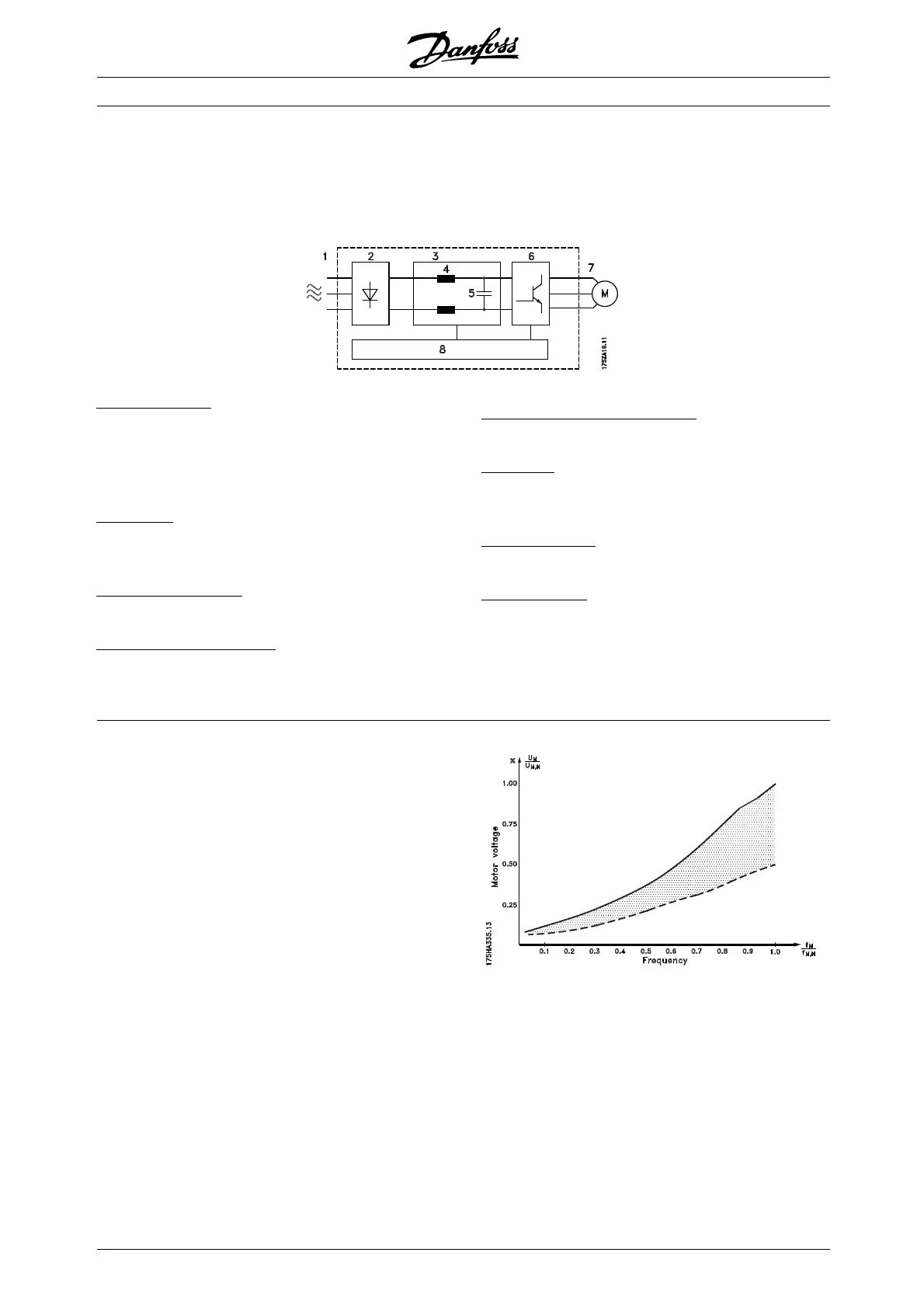

The figure on the right illustrates the working

range of the AEO function, within which energy

optimization is enabled.

If t

he AEO function has been selected in parameter 101,

Torque characteristics, this function will be constantly

active. If there is a major deviation from the optimum U/f

r

atio, the frequency converter will quickly adjust itself.

Advantages of the AEO function

• Automatic energy optimization

• Compensation if an oversize motor is used

• AEO matches operations to daily or

seasonal fluctuations

MG.83.A2.02 - VLT is a registered Danfoss trademark

10

Loading...

Loading...