Minimum speed limit

Parameter 4-12 Motor Speed Low Limit [Hz] sets the

minimum output speed that the drive can provide.

Maximum speed limit

Parameter 4-14 Motor Speed High Limit [Hz] or

parameter 4-19 Max Output Frequency sets the maximum

output speed that the drive can provide.

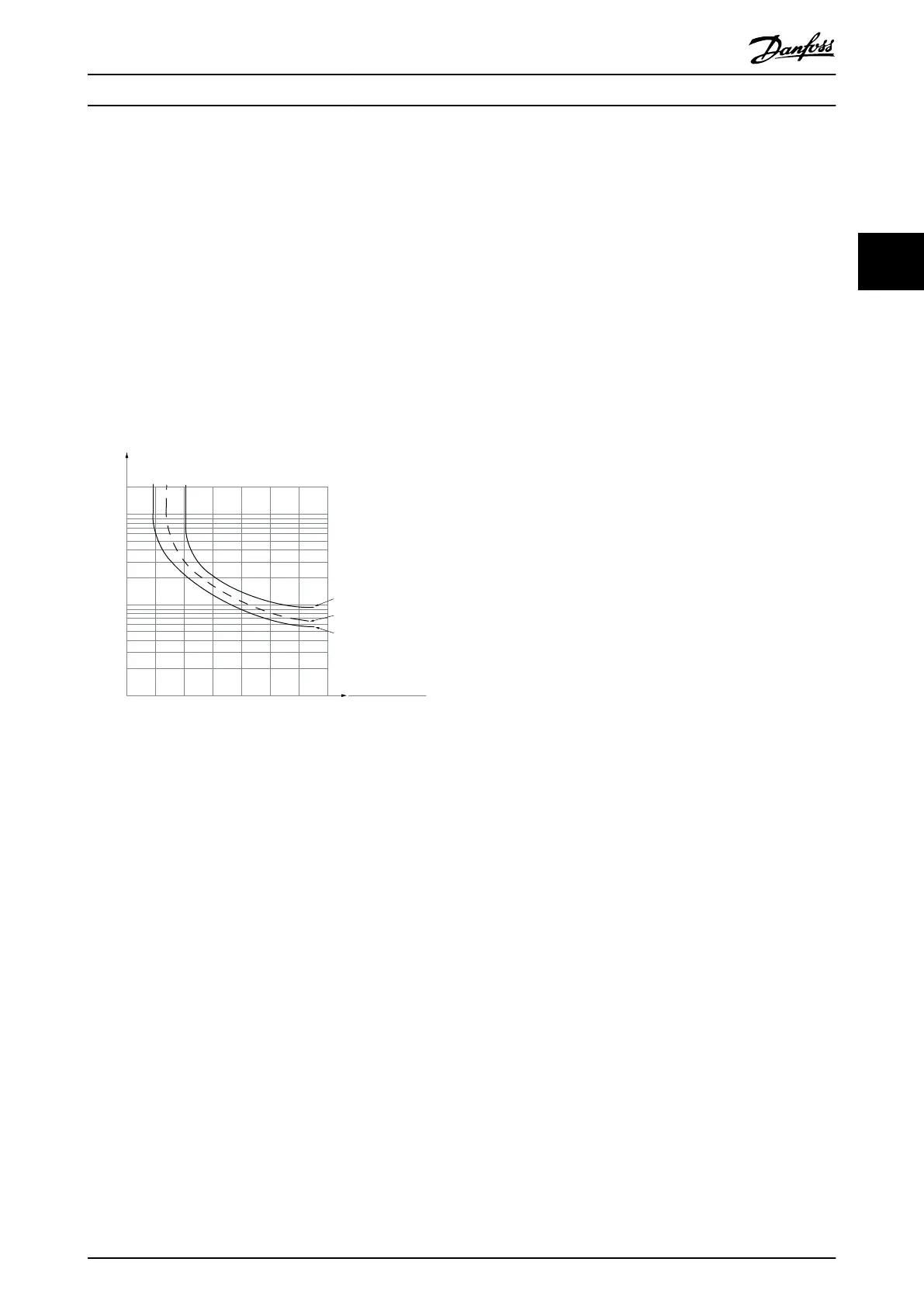

ETR (electronic thermal relay)

The drive ETR function measures the actual current, speed,

and time to calculate motor temperature. The function also

protects the motor from being overheated (warning or

trip). An external thermistor input is also available. ETR is

an electronic feature that simulates a bimetal relay based

on internal measurements. The characteristic is shown in

Illustration 3.1.

1.21.0 1.4

30

10

20

100

60

40

50

1.81.6 2.0

2000

500

200

400

300

1000

600

t [s]

175ZA052.12

f

OUT

= 2 x f

M,N

f

OUT

= 0.2 x f

M,N

f

OUT

= 1 x f

M,N

(par. 1-23)

I

MN

(par. 1-24)

I

M

Illustration 3.1 ETR

The X-axis shows the ratio between I

motor

and I

motor

nominal. The Y-axis shows the time in seconds before the

ETR cuts o and trips the drive. The curves show the

characteristic nominal speed at twice the nominal speed

and at 0.2 x the nominal speed.

At lower speed, the ETR cuts o at lower heat due to less

cooling of the motor. In that way, the motor is protected

from being overheated even at low speed. The ETR feature

calculates the motor temperature based on actual current

and speed. The calculated temperature is visible as a

readout parameter in parameter 16-18 Motor Thermal.

3.3.4 Mains Drop-out

During a mains drop-out, the drive keeps running until the

DC-link voltage drops below the minimum stop level. The

minimum stop level is typically 15% below the lowest

rated supply voltage. The mains voltage before the drop-

out and the motor load determine how long it takes for

the drive to coast.

The drive can be congured (parameter 14-10 Mains Failure)

to dierent types of behavior during mains drop-out:

•

Trip lock once the DC-link is exhausted.

•

Coast with ying start whenever mains return

(parameter 1-73 Flying Start).

•

Kinetic back-up.

•

Controlled ramp down.

Flying start

This selection makes it possible to catch a motor that is

spinning freely due to a mains drop-out. This option is

relevant for centrifuges and fans.

Kinetic back-up

This selection ensures that the drive runs as long as there

is energy in the system. For short mains drop-out, the

operation is restored after mains return, without bringing

the application to a stop or losing control at any time.

Several variants of kinetic back-up can be selected.

Congure the behavior of the drive at mains drop-out in

parameter 14-10 Mains Failure and parameter 1-73 Flying

Start.

3.3.5 Automatic Restart

The drive can be programmed to restart the motor

automatically after a minor trip, such as momentary power

loss or uctuation. This feature eliminates the need for

manual resetting and enhances automated operation for

remotely controlled systems. The number of restart

attempts and the duration between attempts can be

limited.

3.3.6 Full Torque at Reduced Speed

The drive follows a variable V/Hz curve to provide full

motor torque even at reduced speeds. Full output torque

can coincide with the maximum designed operating speed

of the motor. This drive diers from variable torque drives

and constant torque drives. Variable torque drives provide

reduced motor torque at low speed. Constant torque

drives provide excess voltage, heat, and motor noise at less

than full speed.

3.3.7 Frequency Bypass

In some applications, the system can have operational

speeds that create a mechanical resonance. This

mechanical resonance can generate excessive noise and

possibly damage mechanical components in the system.

The drive has 4 programmable bypass-frequency

bandwidths. The bandwidths allow the motor to step over

speeds that induce system resonance.

Product Overview and Featur... Design Guide

MG06K102 Danfoss A/S © 03/2019 All rights reserved. 11

3 3

Loading...

Loading...