Mounting

To adapt to the mounting holes of FC 280, contact the

local Danfoss supplier to order a separate backplate.

To mount the frequency converter:

1. Ensure that the strength of the mounting location

supports the unit weight. The frequency

converter allows side-by-side installation.

2. Locate the unit as close to the motor as possible.

Keep the motor cables as short as possible.

3. Mount the unit vertically to a solid at surface or

to the optional backplate to provide cooling

airow.

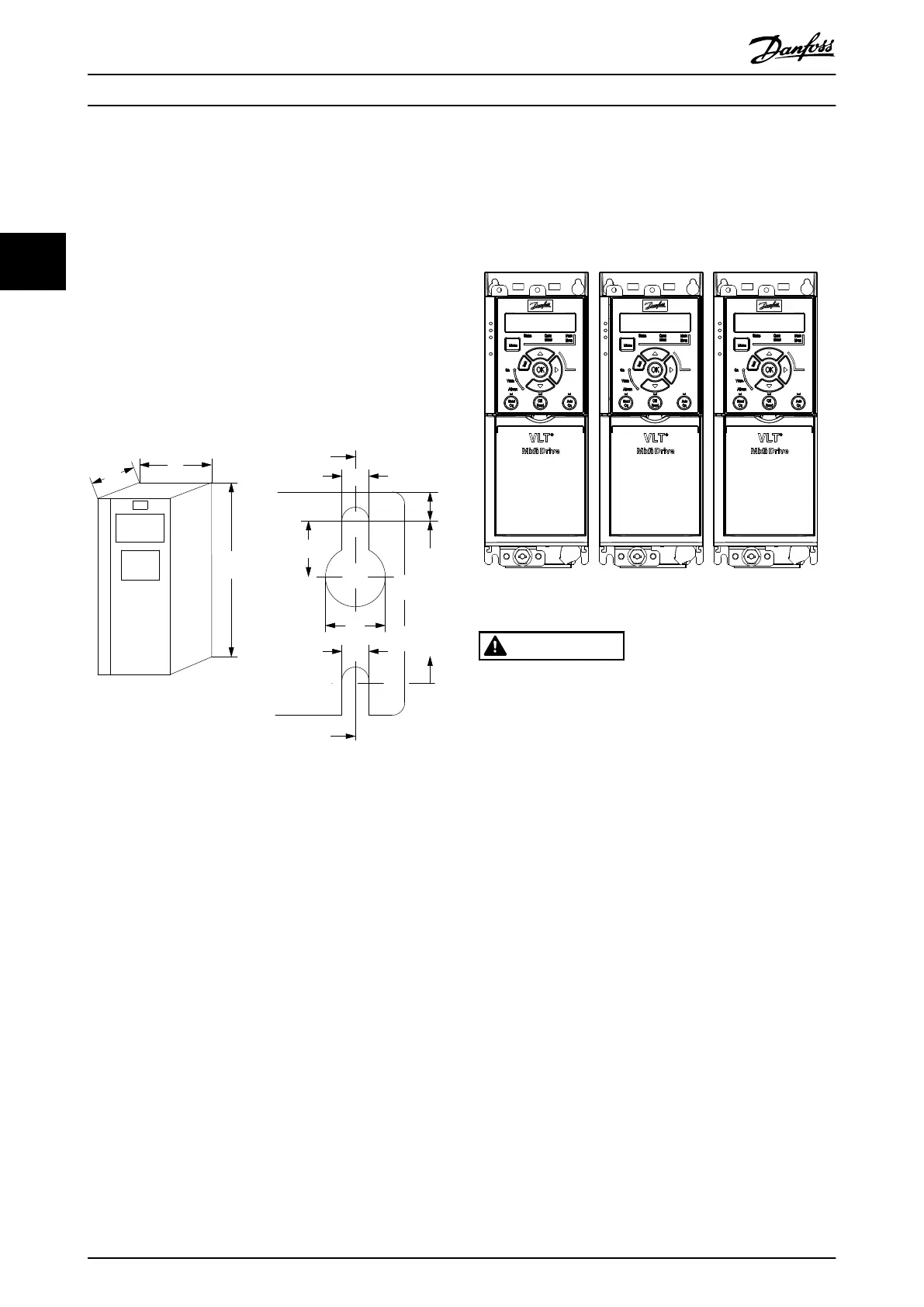

4. When provided, use the slotted mounting holes

on the unit for wall mounting.

Illustration 3.2 Top and Bottom Mounting Holes (See

chapter 9.9 Enclosure Sizes, Power Ratings, and Dimensions)

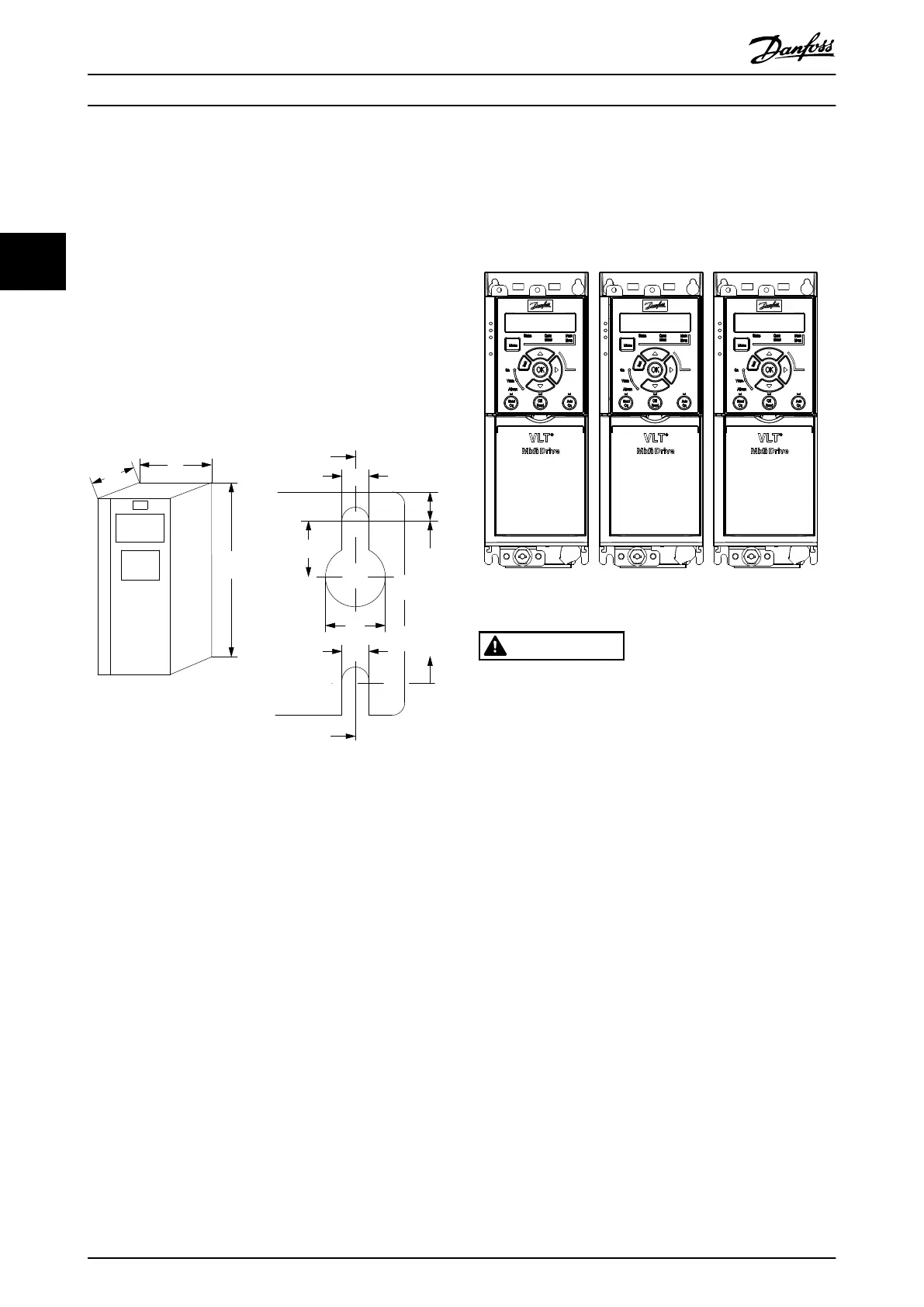

3.3.1 Side-by-side Installation

Side-by-side installation

All FC 280 units can be installed side-by-side in vertical or

horizontal position. The units do not require extra

ventilation on the side.

Illustration 3.3 Side-by-side Installation

CAUTION

RISK OF OVERHEATING

If IP21 solution is used, mounting the units side-by-side

could lead to overheating and unit damages.

•

Avoid mounting the units side-by-side if IP21

solution is used.

3.3.2 Bus Decoupling Kit

The bus decoupling kit ensures mechanical xation and

electrical screening of cables for the following control

cassette variants:

•

Control cassette with PROFIBUS.

•

Control cassette with PROFINET.

•

Control cassette with CANopen.

•

Control cassette with Ethernet.

Each bus decoupling kit contains 1 horizontal decoupling

plate and 1 vertical decoupling plate. Mounting the

vertical decoupling plate is optional. The vertical

decoupling plate provides better mechanical support for

PROFINET and Ethernet connectors and cables.

Mechanical Installation

VLT

®

Midi Drive FC 280

8 Danfoss A/S © 11/2015 All rights reserved. MG07A102

33

Loading...

Loading...