3.3.3 Mounting

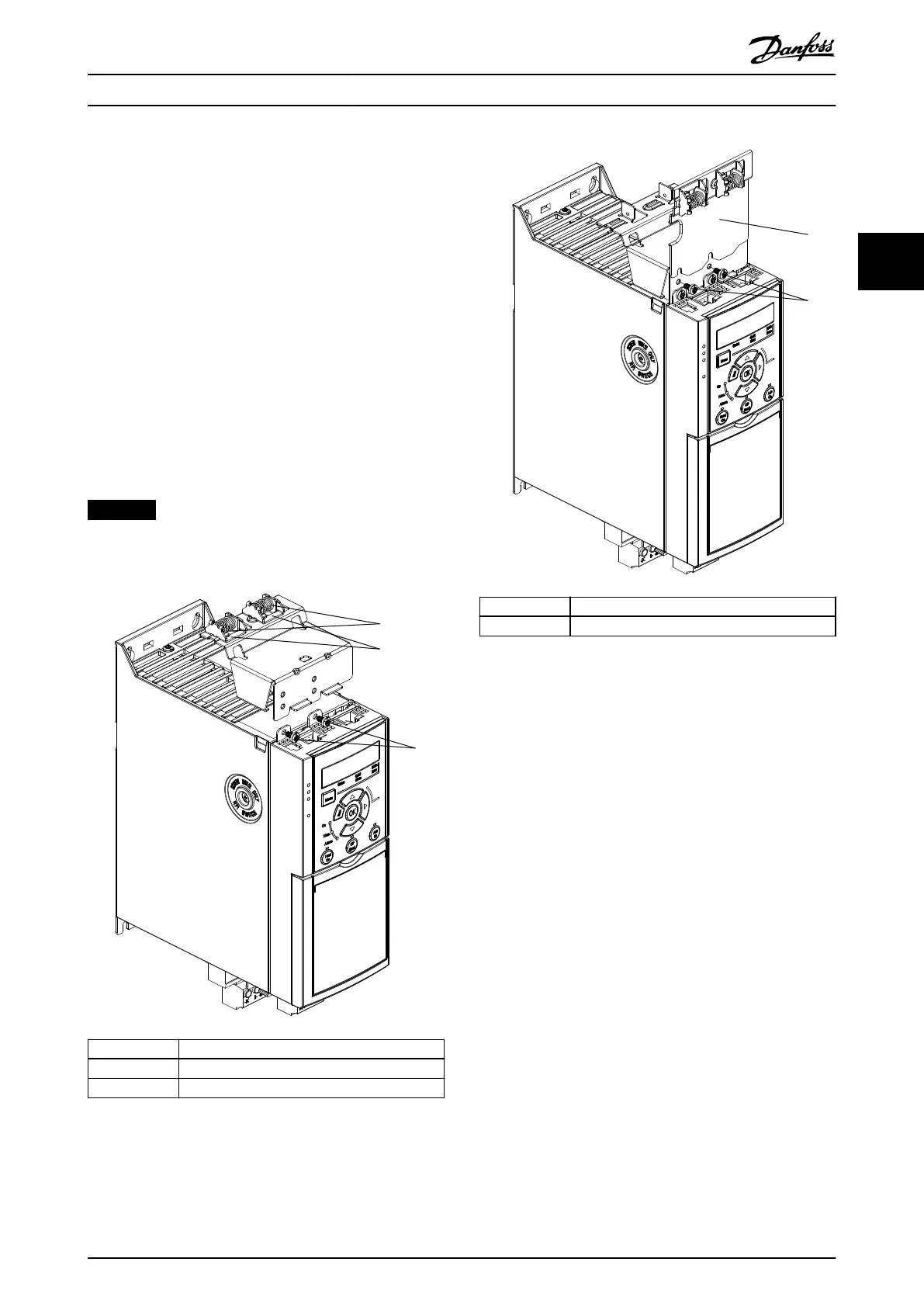

To mount the bus decoupling kit:

1. Place the horizontal decoupling plate on the

control cassette that is mounted on the

frequency converter, and fasten the plate using 2

screws, as shown in Illustration 3.4. Tightening

torque 0.7–1.0 Nm.

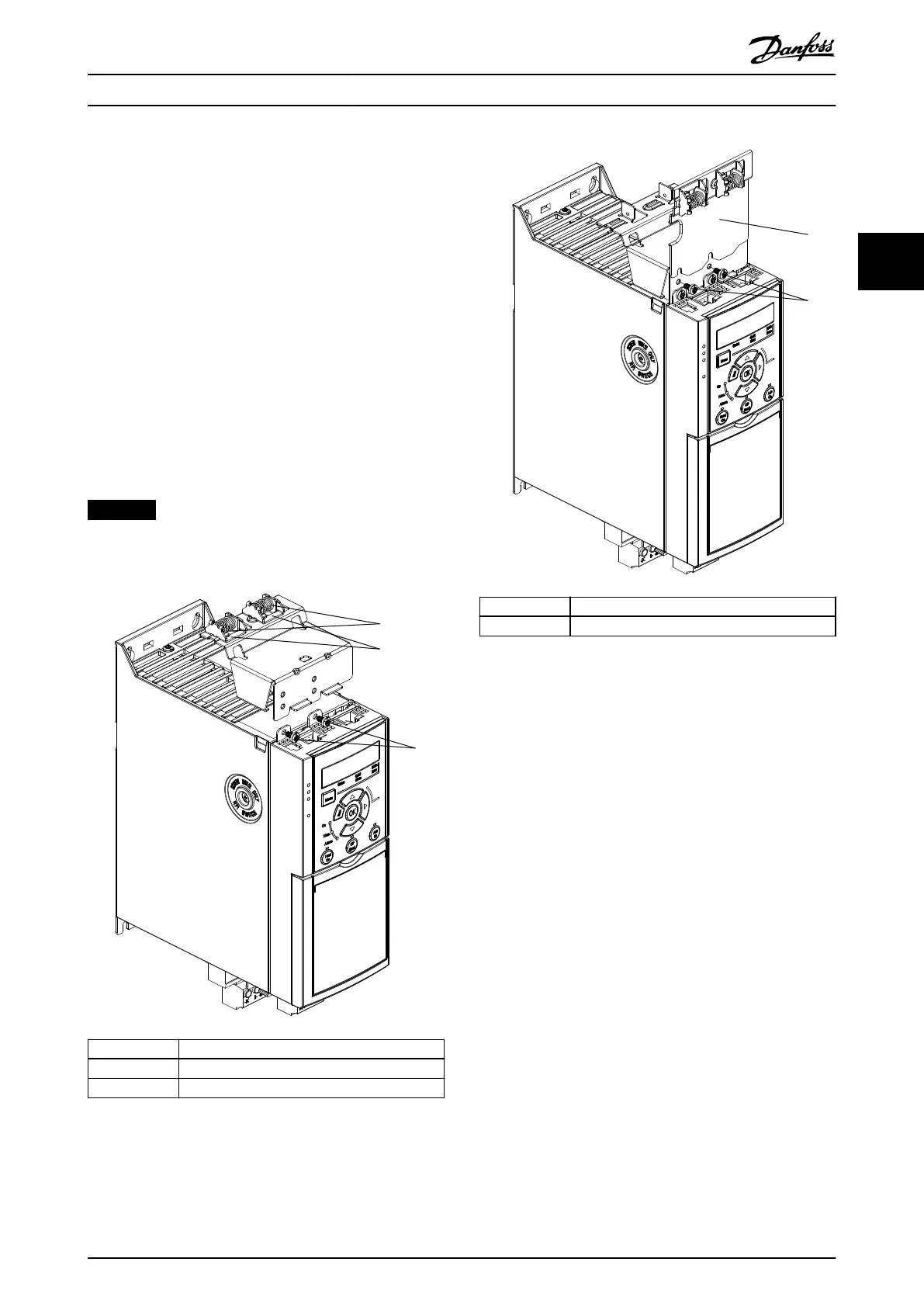

2. Optional: Mount the vertical decoupling plate as

follows:

2a Remove the 2 mechanical springs and 2

metal clamps from the horizontal plate.

2b Mount the mechanical springs and

metal clamps on the vertical plate.

2c Fasten the plate with 2 screws, as shown

in Illustration 3.5. Tightening torque 0.7–

1.0 Nm.

NOTICE

If the IP21 top cover is used, do not mount the vertical

decoupling plate, because its height aects the proper

installation of the IP21 top cover.

1 Mechanical springs

2 Metal clamps

3 Screws

Illustration 3.4 Fasten the Horizontal Decoupling Plate with

Screws

1 Vertical decoupling plate

2 Screws

Illustration 3.5 Fasten the Vertical Decoupling Plate with

Screws

Both Illustration 3.4 and Illustration 3.5 show PROFINET

sockets. The actual sockets are based on the type of the

control cassette mounted on the frequency converter.

3. Push the PROFIBUS/PROFINET/CANopen/Ethernet

cable connectors into the sockets in the control

cassette.

4. 4a Place the PROFIBUS/CANopen cables

between the spring-loaded metal

clamps to establish mechanical

xation

and electrical contact between the

screened sections of the cables and the

clamps.

4b Place the PROFINET/Ethernet cables

between the spring-loaded metal

clamps to establish mechanical xation

between the cables and the clamps.

Mechanical Installation Operating Instructions

MG07A102 Danfoss A/S © 11/2015 All rights reserved. 9

3 3

Loading...

Loading...