Setting the PROFIBUS address with set station address

command

1. Switch o the supply.

2. Set the DIP switch to 126 or 127 (factory switch

setting).

3. Set the address via the set station address

command. Use the set station address command

to lock the programmed address and to change

the address. To unlock the address setting,

change parameter 9-18 Node Address or the

address switch, followed by a power cycle. A new

address is eective immediately after applying

the set station address command.

3.2 Congure the Master

3.2.1 GSD File

To congure a PROFIBUS master, the conguration tool

needs a GSD le for each type of slave on the network.

The GSD le is a PROFIBUS DP standard text le containing

the necessary communications set-up data for a slave.

Download the GSD

le for the relevant frequency

converter series vlt-drives.danfoss.com/products/engineering-

software/software-download/eldbus/.

PROFIBUS SW version

(parameter 15-61 Option SW

Version)

GSD le

1.x da01040A.GSD

2.x da02040A.GSD

FCD 302 da01040B.GSD

Table 3.2 GSD File

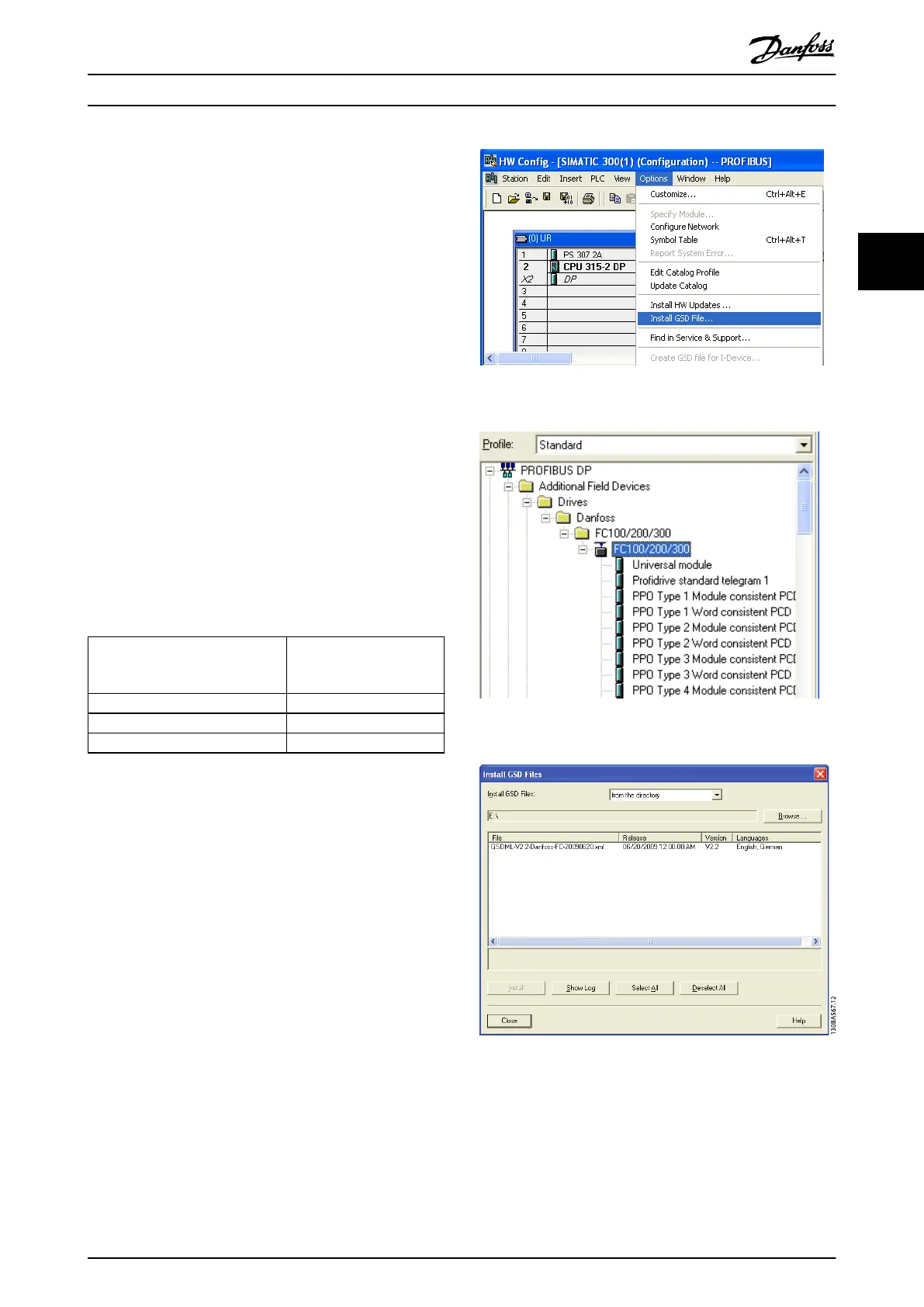

The following example shows the procedure of

conguring

a PROFIBUS master for FC 301/FC 302, but the procedure is

also valid for other frequency converter series.

1. Import the GSD

le in the conguration tool.

2. Import the GSD le to the Simatic Manager

software tool. Import a GSD le once only for

each frequency converter series, following the

initial installation of the software tool. See

Illustration 3.3.

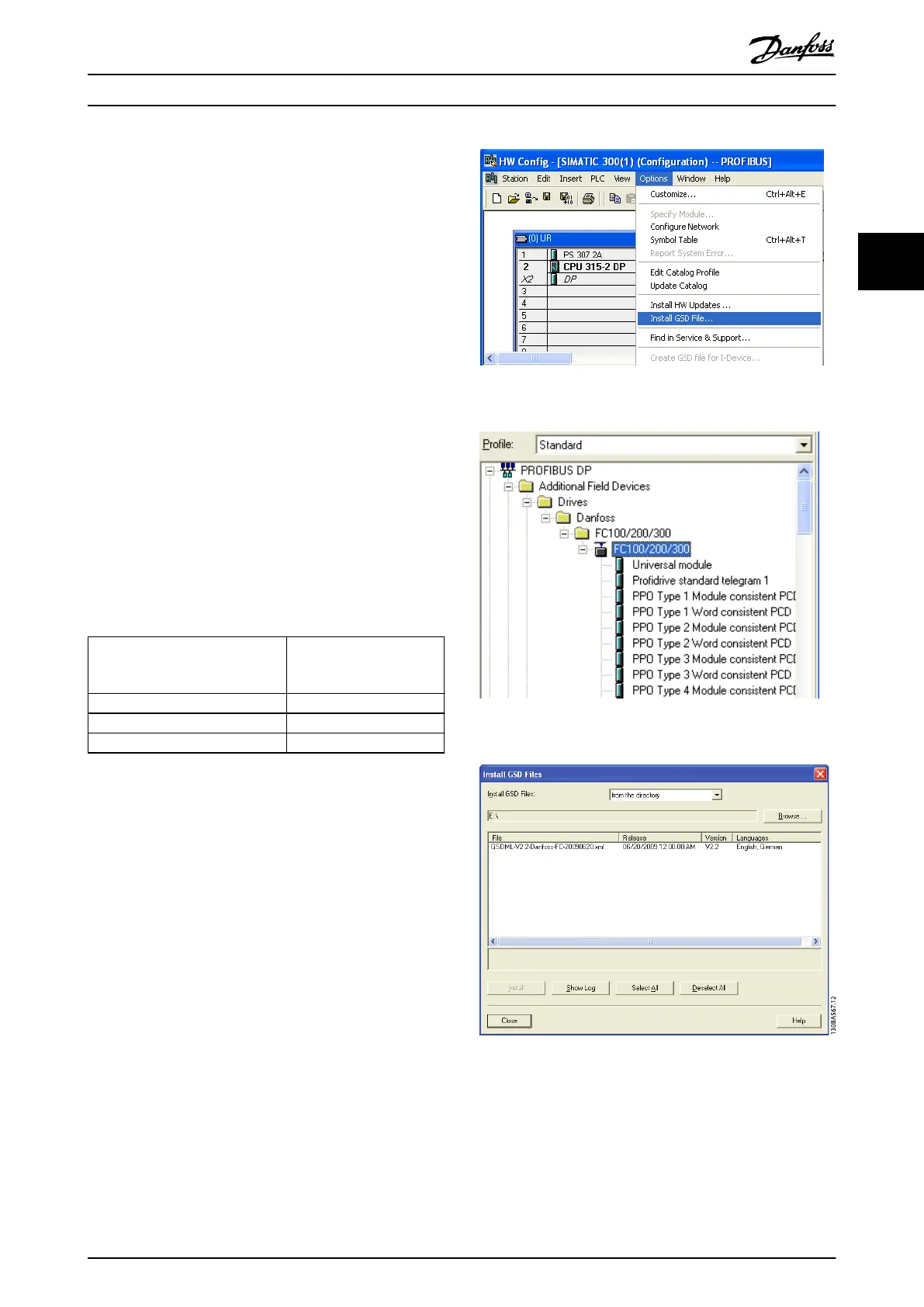

3. Use the browser for the GSD le, install all les,

and import both a GSD le and a bitmap for the

device into the hardware catalog. See

Illustration 3.4 and Illustration 3.5.

Illustration 3.3 Install GSD File

Illustration 3.4 Import a GSD File and a Bitmap

Illustration 3.5 Add a GSD File

Conguration Programming Guide

MG37G202 Danfoss A/S © 01/2016 All rights reserved. 9

3 3

Loading...

Loading...