4

3. APPLICATIONS

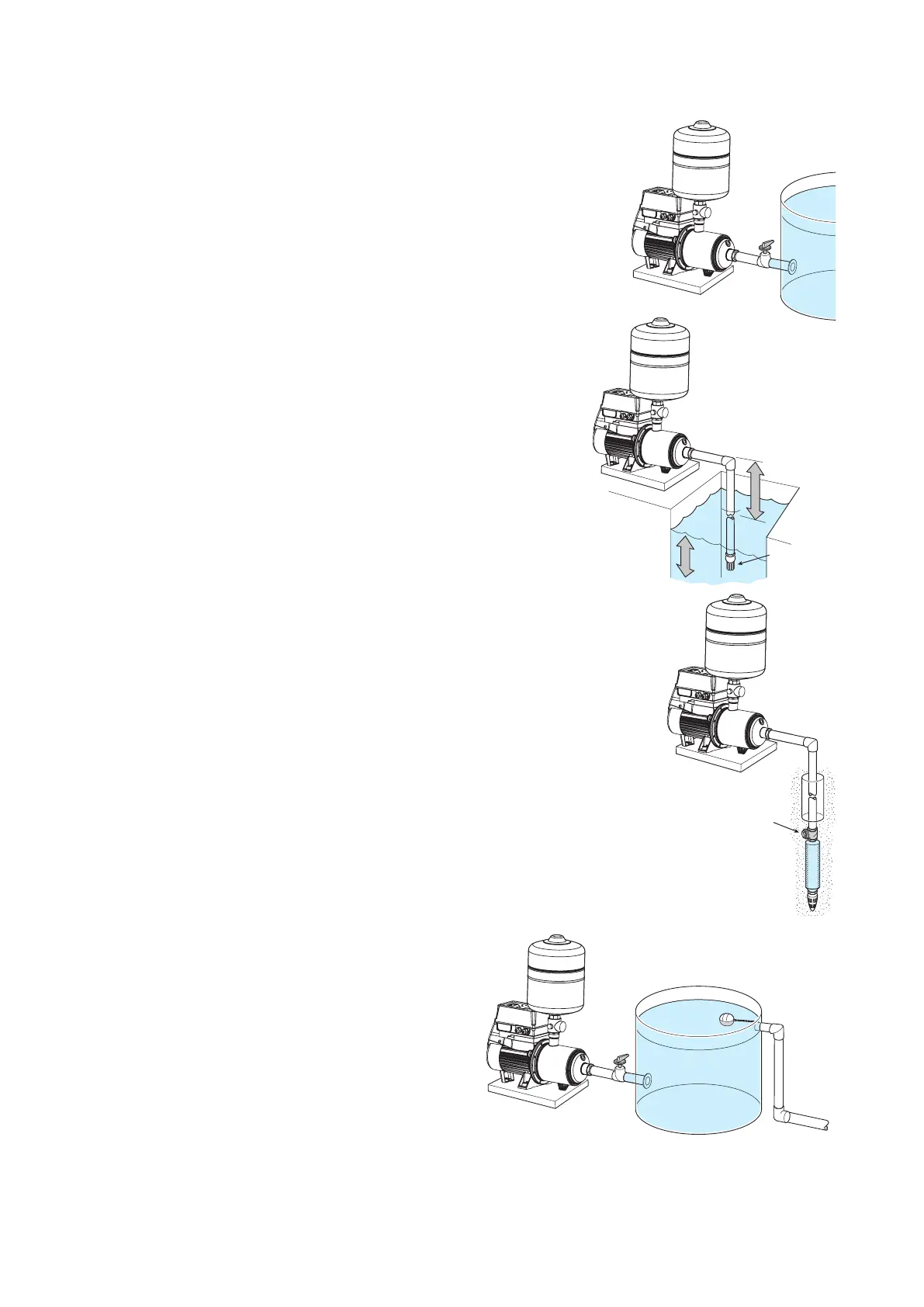

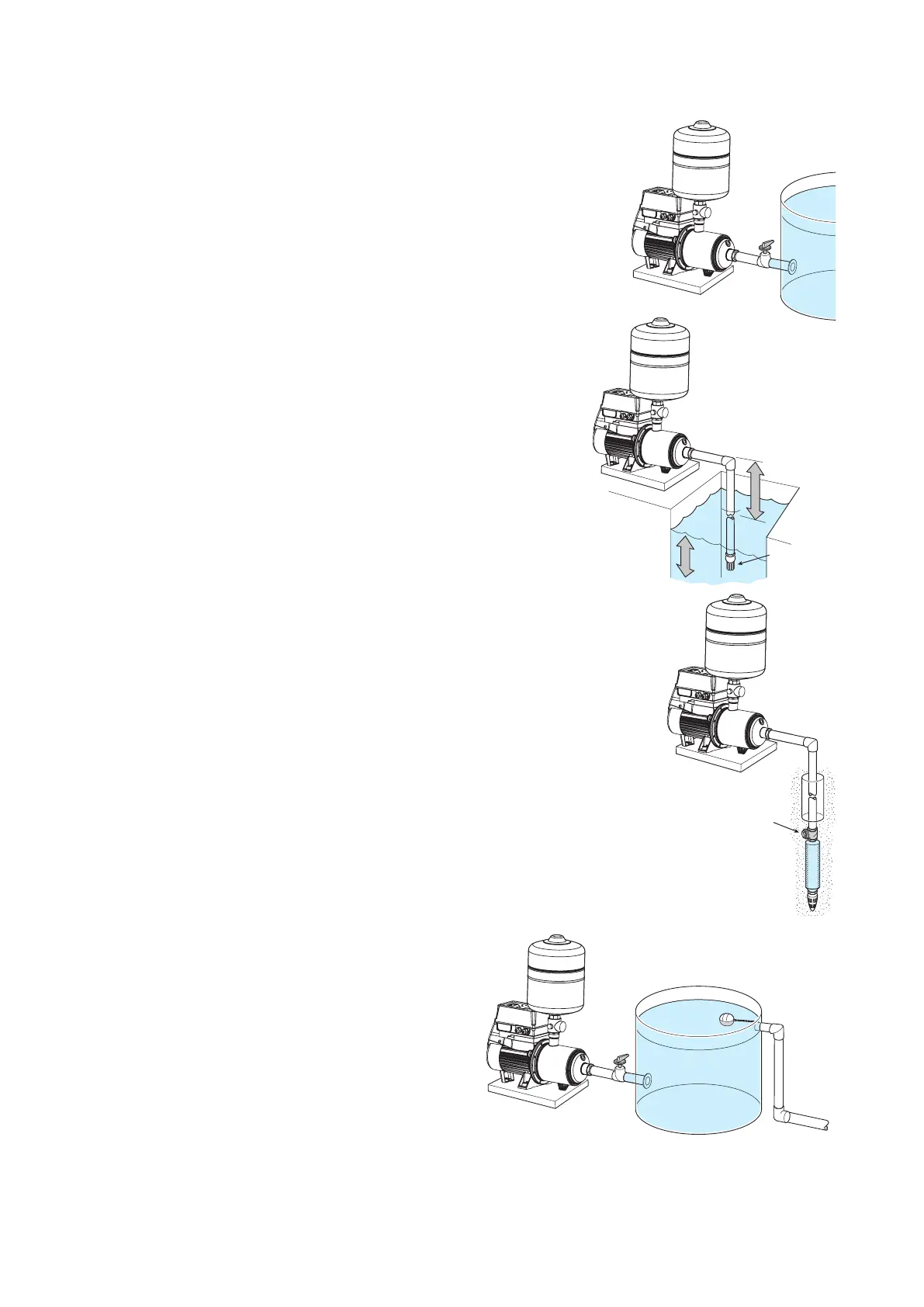

3.1 Above ground water sources (flooded suction)

Installations with flooded suction require a gate valve so water supply can be

turned off for pump removal and servicing, see figure 3.1. There is no need

to install a one-way check valve in the suction pipeline as there is a one-way

check valve installed in the tee piece immediately on top of the DynaDrive

pump discharge.

3.2 In-ground water sources (eg suction lift from in ground tank)

Whenever the installation position of the pump is higher than the lowest

water level, a foot valve should be fitted to the end of the suction pipe, see

figure 3.2. Ensure that the foot valve is at least ½ metre (1⅔ feet) below

minimum water level to avoid a vortex of air being drawn into pipe.

In suction lift installations that have an unreliable foot-valve it may

be preferable to remove the check valve in the DynaDrive discharge

tee piece. Doing so will allow the DynaDrive pressure transducer to

“recognise” a loss of water from a suction line, while the DynaDrive

is in standby. Applications of this nature, with long &/or wide suction

lines consist of a considerable volume of water, ie > 100 litres (26

US gallons) in the suction pipe. Temperature variations of the water

may create fluctuations in the pressure of the water, falsely triggering

the DynaDrive to start/stop. In such as case, it is worth considering

upsizing the pressure tank to help absorb these pressure fluctuations. If

concerned, please consult your Davey representative.

3.3 Spear point installations

When a pump is installed on a spear, or well point, a check valve fitted immediately

on top of the spear point itself, see figure 3.3. Do not install the check valve at the

pump, or at the top of the well. Do not run the pump without water in it.

In suction lift installations that have an unreliable foot-valve it may be preferable to

remove the check valve in the DynaDrive discharge tee piece. Doing so will allow

the DynaDrive pressure transducer to “recognise” a loss of water from a suction line,

while the DynaDrive is in standby. Applications of this nature, with long &/or wide

suction lines consist of a considerable volume of water, ie > 100 litres (26 US gallons)

in the suction pipe. Temperature variations of the water may create fluctuations in

the pressure of the water, falsely triggering the DynaDrive to start/stop. In such as

case, it is worth considering upsizing the pressure tank to help absorb these pressure

fluctuations. If concerned, please consult your Davey representative.

3.4 Connecting mains scheme or town water supply to either

suction, or discharge of pumps and pressure systems

Most Water Supply Authorities have strict regulations

regarding direct connection of pumps to mains water

supplies. In most cases an isolating tank is required

between mains supply and pump, see figure 3.4. Davey

also recommend this method. Directly applied mains

pressure can exceed pump operating pressure and

damage pump. Davey Water Products Pty Ltd cannot

accept responsibility for loss, or damage resulting from

incorrect, or unauthorized installations.

Figure 3.1

MAINS WATER

Figure 3.4

Figure 3.2

> 1m

> 0.5m

Foot valve

(Not Supplied)

Figure 3.3

Check valve

Loading...

Loading...