7

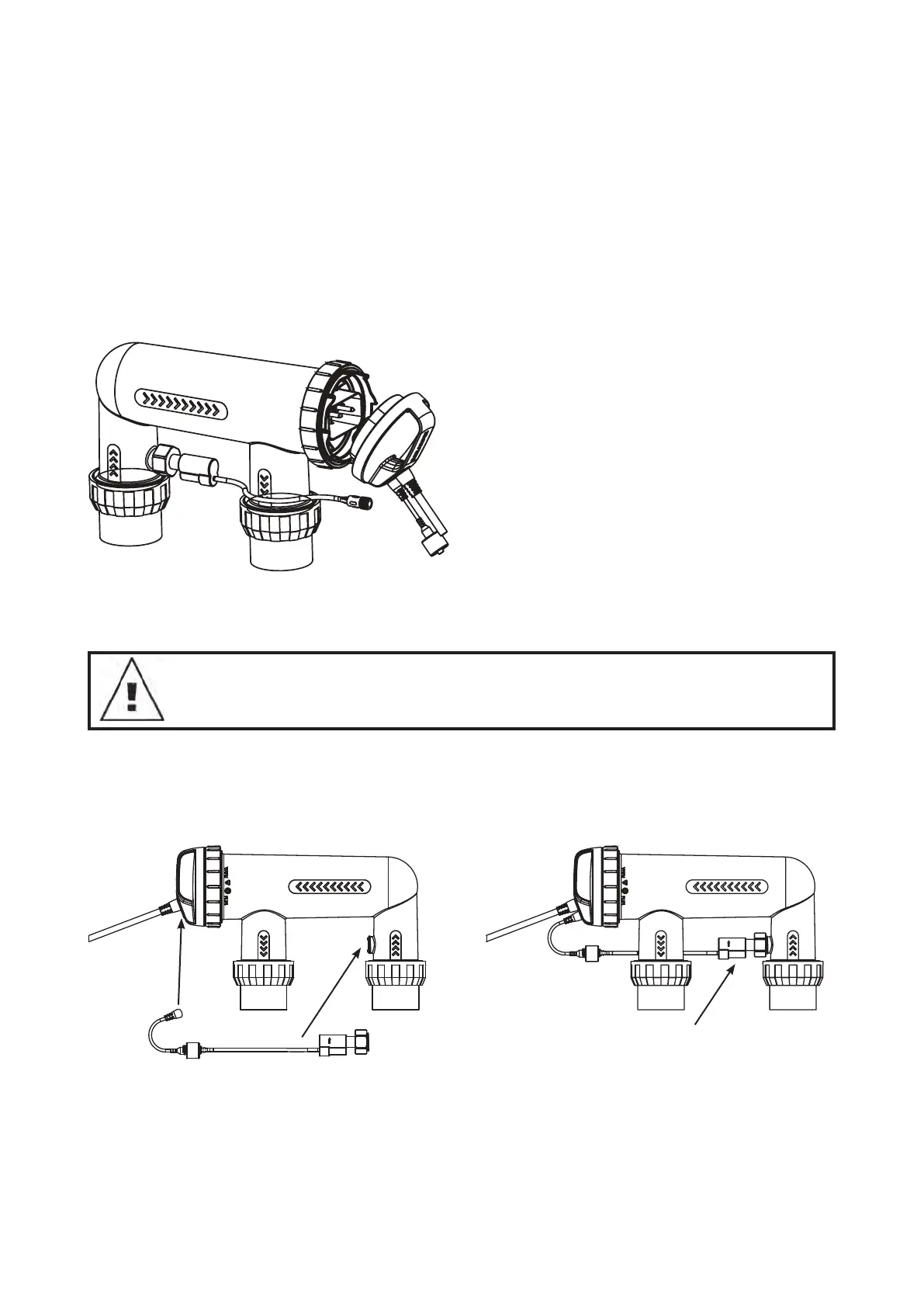

4.2 INSTALLING THE CELL

The ChloroMatic Nipper cell should always by the last appliance in your system. Ensure the cell is installed

after pumps, filters and any heating appliances. To achieve best efficiency, the ChloroMatic Nipper cell should

be installed such that turbulent water is limited as much as possible. When installing a 90° elbow before the

cell’s inlet barrel union, ensure there’s equivalent to 5 x pipe diameter of straight pipe between the elbow and

the union. That is, if the pipe diameter is 40mm, straight pipe entering the barrel union should be no less than

200mm in length. Isolation valves (used where equipment is located below pool water level) should also be

installed no closer than 5 x pipe diameter from the inlet barrel union. This will assist laminar flow.

5. CONNECTING THE ELECTROLYTIC CELL TO THE POWER SUPPLY

The Nipper salt water sanitiser uses a reverse polarity electrolytic cell for low maintenance operation. The

ChloroMatic Nipper power supply is fitted with a flexible lead terminated with the cell connectors built into a

plastic moulding. The three in-line connectors are not “polarity sensitive”.

NOTE: The ChloroMatic Nipper cell is supplied with a paddle type flow switch, which is to be installed

on the cell as shown in the diagram on page 4 and connected to the cell lead via the connector on

the end of the cable.

IMPORTANT: The ow switch must be mounted with the highlighted arrow on side of

the switch pointing in the direction of ow.

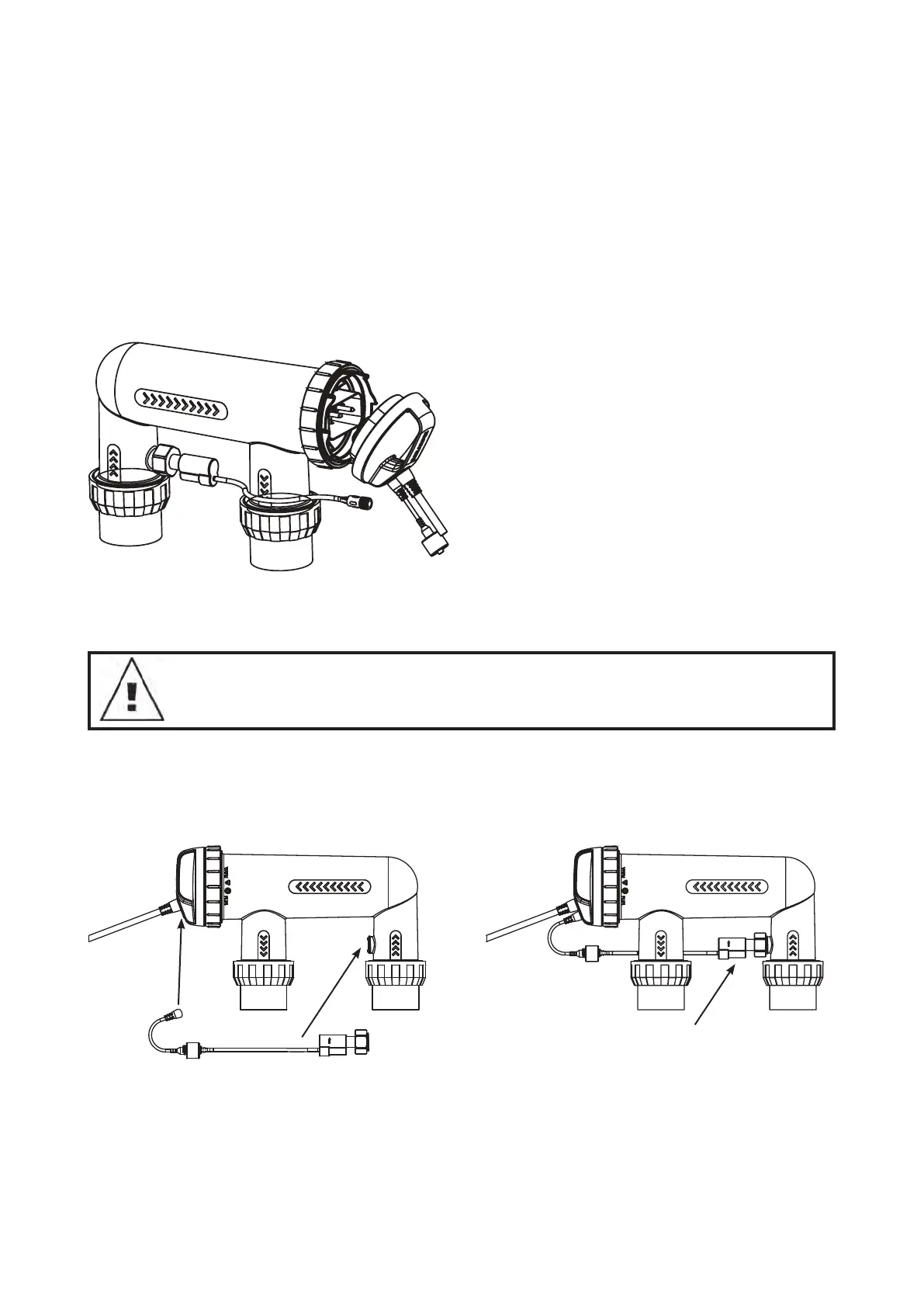

6. CONNECTING THE FLOW SWITCH TO THE CELL HOUSING

Ensure that the flow switch is installed into the cell housing.

Ensure the flow switch direction is correct (see page 4)

Figure 6.1 Figure 6.2

Fitted

Figure 5.1

Loading...

Loading...