7

USER Section (en)

7679433.01 (3-06/17)

154

Delivery/return probe control test Call the Authorised Service Centre.

160

Fan fault Call the Authorised Service Centre.

178

Intervention of safety thermostat for excess temperature in

low temperature system

Call the Authorised Service Centre.

270

Overheating exchanger Call the Authorised Service Centre.

317 162

Call the Authorised Service Centre. Call the Authorised Service Centre.

321 163

Call the Authorised Service Centre. Call the Authorised Service Centre.

384 164

Parasite ame (internal error)

Press and hold down

for at least 2 seconds.

385 165

Input voltage too low

Automatic reset at voltages in excess of 175V. If this fault

persists, call the Authorised Service Centre.

431

Exchanger sensor faulty Call the Authorised Service Centre.

In the event of a fault, the display backlighting indicates the error code. 5 reset attempts can be performed after which the

boiler shuts down. Wait 15 minutes before attempting to reset the boiler again.

5. BOILER INFORMATION MENU

Press and hold down for at least 1 second, to display the information indicated in the table. Press to exit.

DESCRIPTION DESCRIPTION

00 Secondary fault internal code 06 Heating return temperature (°C)

01 Heating supply temperature (°C) 07 Flue sensor temperature (°C)

02 Outdoor temperature (°C) 08 Primary exchanger temperature (°C)

03 Indirect tank DHW temperature (boiler CH only) 09 - 13 Manufacturer information

04

Domestic hot water temperature

(boiler with plate exchanger)

14 Identication Open Therm communication

05 Water pressure in heating system (bar) 15 - 18 Manufacturer information

6. SWITCHING OFF THE BOILER

To turn off the boiler, disconnect the electric power supply using the two-pole switch. In the “Off” operating mode the boiler stays

off but the electrical circuits remain powered and the anti-freeze function remains active.

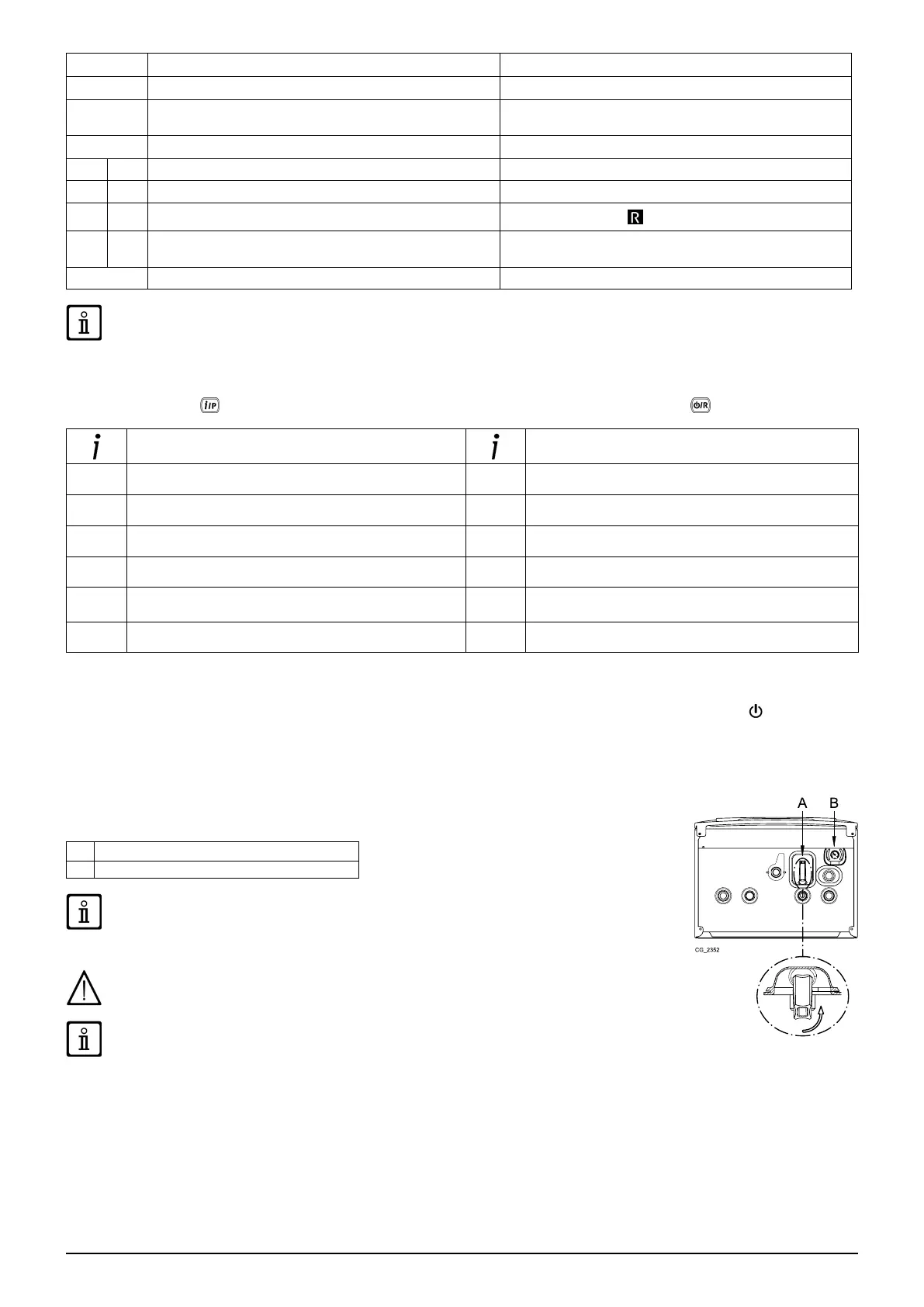

7. FILLING THE SYSTEM

Regularly check that the pressure displayed on the pressure gauge B is 1 - 1.5 bar, with the boiler

cold. If the pressure is too low, turn tap "A" to ll the boiler (gure to side).

A Boiler/system lling tap

B Pressure gauge

Take special care when lling the heating system. In particular, open any thermostat valves in

the system, ensure the water enters slowly in order to prevent the formation of air inside the

primary circuit until operating pressure is reached. Lastly, vent any radiators in the system.

De Dietrich declines all liability for damage deriving from the presence of air bubbles in the primary

exchanger due to the incorrect or imprecise observance of the above.

The boiler is tted with a hydraulic pressure gauge which prevents the boiler from working if

there is no water.

If pressure drops occur frequently, have the boiler checked by the AUTHORISED TECHNICAL

SERVICE CENTRE.

8. ROUTINE MAINTENANCE INSTRUCTIONS

To keep the boiler efcient and safe, have it checked by the Authorised Service Centre at the end of every operating period.

Careful servicing ensures economical operation of the system.

bis

Loading...

Loading...