14

WHAT FACTORS AFFECT SANDING OPERATIONS?

A. SANDING BELT GRIT

1. 36 grit – Used for very aggressive stock removal, glue removal, or for sanding rough boards. Leaves a rough

finish.

2. 60 grit – Used for heavy stock removal and rough surfaces, and for truing warped material. Leaves a rough

finish.

3. 80 grit – Used for general purpose sanding, stock removal, surfacing, and rough finishing. Leaves a marked

finish.

4. 120 grit – Used for minimal stock removal and for finishing. Leaves a fine marked finish.

5. 180 grit. – Used for fine finishing. Leaves a smooth finish.

6. 220 grit – For very fine finishing. Leaves a very smooth finish.

For best results, sand first with a coarse grit belt, and work toward a finer grit belt.

IMPORTANT: Sanding progression should not exceed more than two belt grits at one time. Watch for the sawdust

loading and dulling of the grit. The extra load will cause the sander to work inefficiently.

B. WIDTH OF BOARD

As board width increases the load on the belt and motor also increases. This additional loading can be reduced

by:

a. reducing the conveyor belt speed.

b. reducing the depth of stock removal.

NOTE: The sander will remove stock to a maximum width of 18" (46 cm) in one pass.

C. TYPES OF WOOD

Hardwoods (oak, hickory, cherry), knots, rosin, or wet wood all place a heavy load on the sander. To make your

sander work more efficiently:

a. reduce the conveyor belt speed.

b. reduce the depth of stock removal.

D. CONVEYOR BELT SPEED

The conveyor belt speed is 0 - 12 feet per minute.

To control the speed of the conveyor belt, turn the knob counter-clockwise to slow it down and clockwise to speed

it up.

Stock can be removed more quickly by using a fast speed, but the machine works much harder, and the wood is

left with a rougher finish. Slowing the speed will lighten the load of the sander, and make the finish better, but it

will increase the sanding time.

WHEN DO I CHANGE THE DRUM SPEED?

The machine has two drum settings:

a. High Speed (3300 SFPM). This setting should mostly be used with a finer grit belt with the conveyor belt speed

set to very slow. The material removal should be set at a very low amount, with increases not to exceed 1/16

of a handwheel turn. Example: A 1/4 turn is 90°, 1/8 turn is 45°, 1/16 turn is 22.5°.

b. Low Speed (2210 SFPM). Used for general purpose sanding, stock removal, surfacing, and rough finishing.

The machine is shipped from the factory set on the low speed. To change to the higher speed, refer to "CHANGING

DRUM SPEEDS/REPLACING DRIVE BELT" in this manual for instructions.

FREQUENTLY ASKED QUESTIONS

system attached. Use a dust collection system with at least 400 to 600

CFPM capacity.

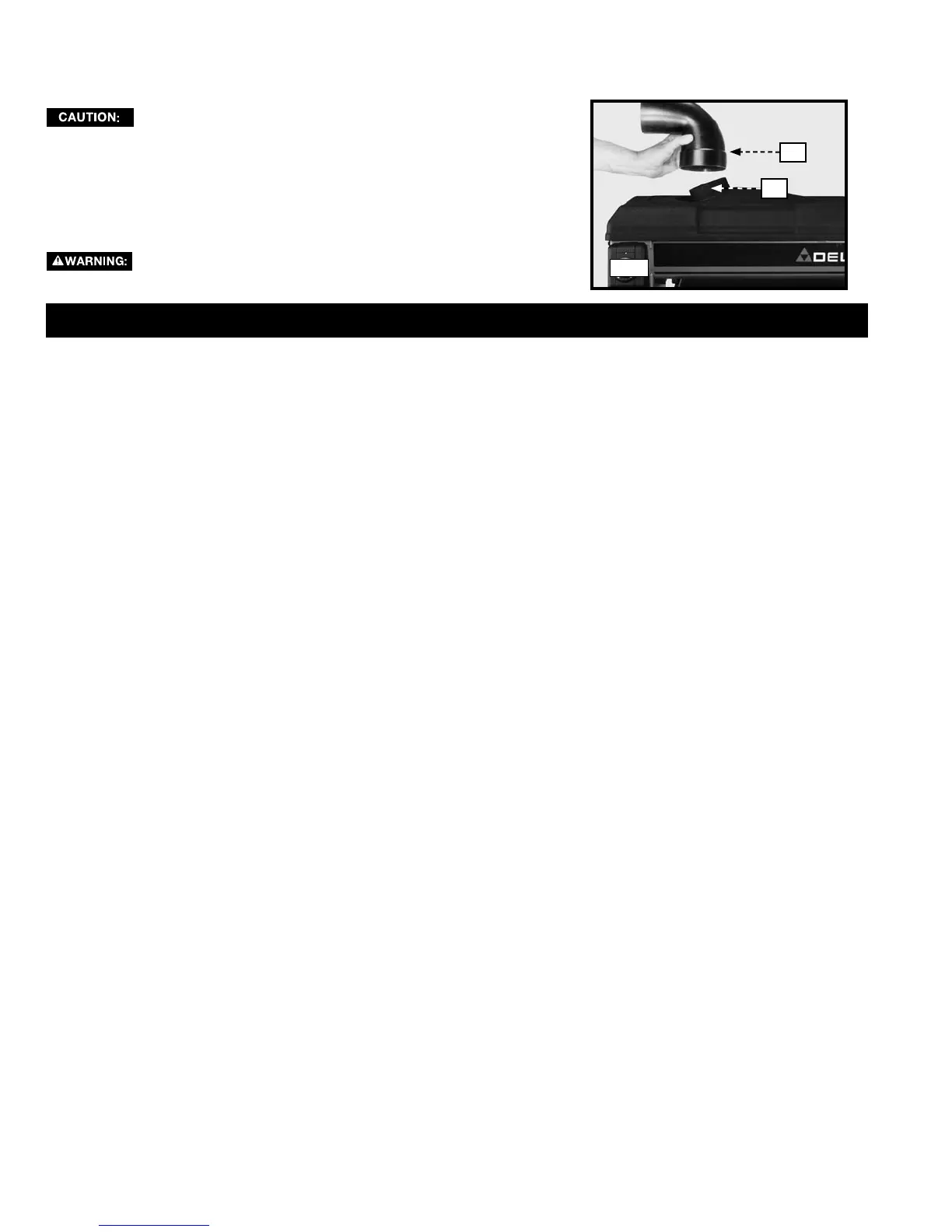

Attach a 4" hose to the hood, or attach an accessory dust collector elbow

(B) Fig. 36 to the dust chute (A). Attach the dust collection system to the

elbow (B).

HOW TO SET UP FOR DUST COLLECTION

dust chute.

Fig. 36

B

A

The drum cover has a 4" O.D. dust chute (A) Fig. 36 that connects to a dust collection system.

Loading...

Loading...