Chapter 7 Motion Control ASDA-A2R Series

Revision December, 2014 7-35

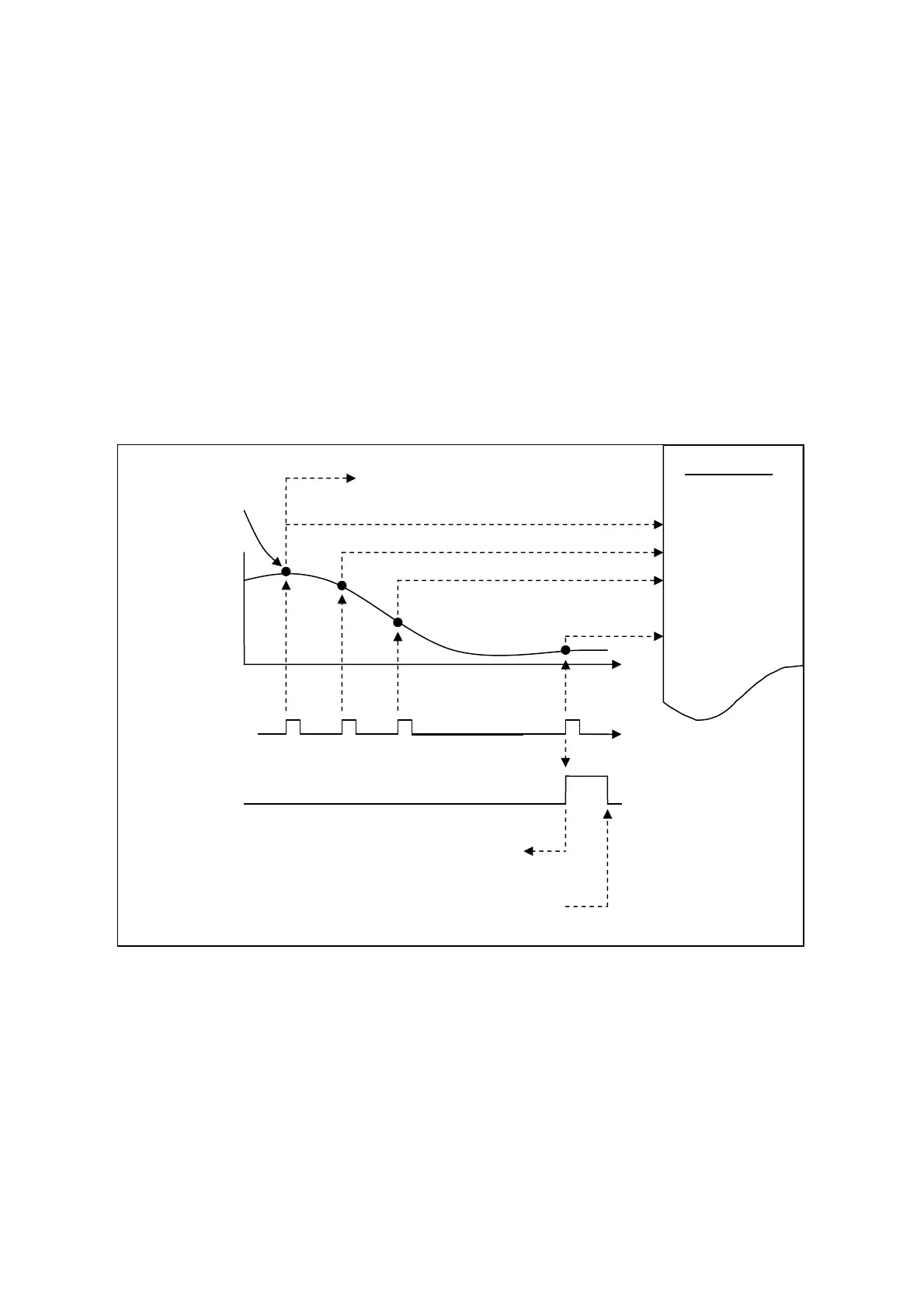

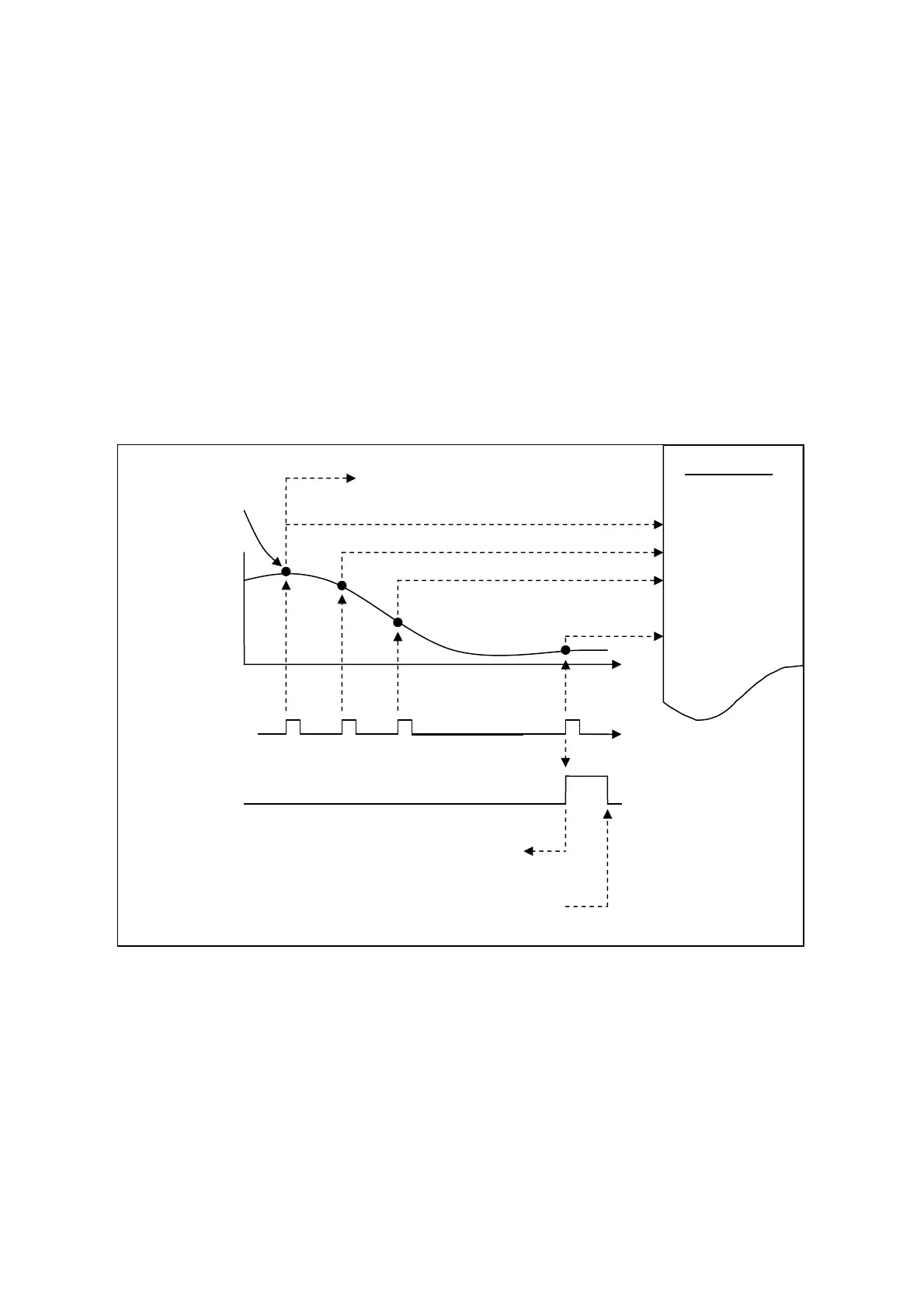

The CAP data is saved in data array and the first CAP data locates in P5-36. The CAP

number has no limit, thus it can be set via P5-38. The last CAP data is saved in P5-36

+P5-38-1. Set the value of P5-39 X, Bit0 to 1 so as to activate CAP function. Every

time when DI7 is triggered, one data will be captured and saved in data array. Then, the

value of P5-38 will decrease one automatically until the CAP number reaches the

setting value (P5-38 = 0). The CAP procedure is completed, the setting value of P5-39

X, Bit0 will be cleared to 0 and DO.CAP_OK is ON.

When capturing the first data, the position of CAP axis can be reset. The first CAP value

will be the value set by P5-76. And the value of the second CAP data will be the

incremental value from the first data. This method is called Relative Capture. If not

selecting the first data reset, it is called Absolute Capture.

When capturing the first data, it automatically activates COMPARE function, which

means the COMPARE function is activated via DI5.

The diagram of CAP:

Position of

CAP Axis

(P5-37)

CAP signal:

(DI7)

DO.CAP_OK:

1 2 3 N

Data Array

…..

POS 1

POS 2

POS 3

~

POS N

CAP is completed and set P5-39.X0 to 0.

PR procedure #50 can be triggered.

The CAP number is

set via P5-38

P5-39.X0=1 to activate the next CAP and switch off DO.

The 1

st

axis

position can

be reset to

the value as

P5-76

The 1

st

oint is saved in P5-36.

The 2nd

oint is saved in P5-36+1.

The 3

rd

oint is saved in P5-36+2

Automatically activate COMPARE

Loading...

Loading...