DVP-ES2/EX2/EC5/SS2/SA2/SX2/SE&TP Operation Manual - Programming

-166

Mask function on Y0 will be enabled when D1026 and D1027 are specified with values other

than 0. Mask function is disabled when D1026 and D1027 are specified with 0. If pulse

output process can not reach the target speed, PLC will clear DD1026 to disable the Mask

function. If the Mask range is set to be within the ramp-up section, PLC will automatically

modify DD1026 to be longer than the ramp-up section. On the other hand, if DD1026 is set

between ramp- down section, PLC will modify DD1026 to be the range before the beginning

of ramp-down process. Mask function setting method on Y2 is the same as Y0.

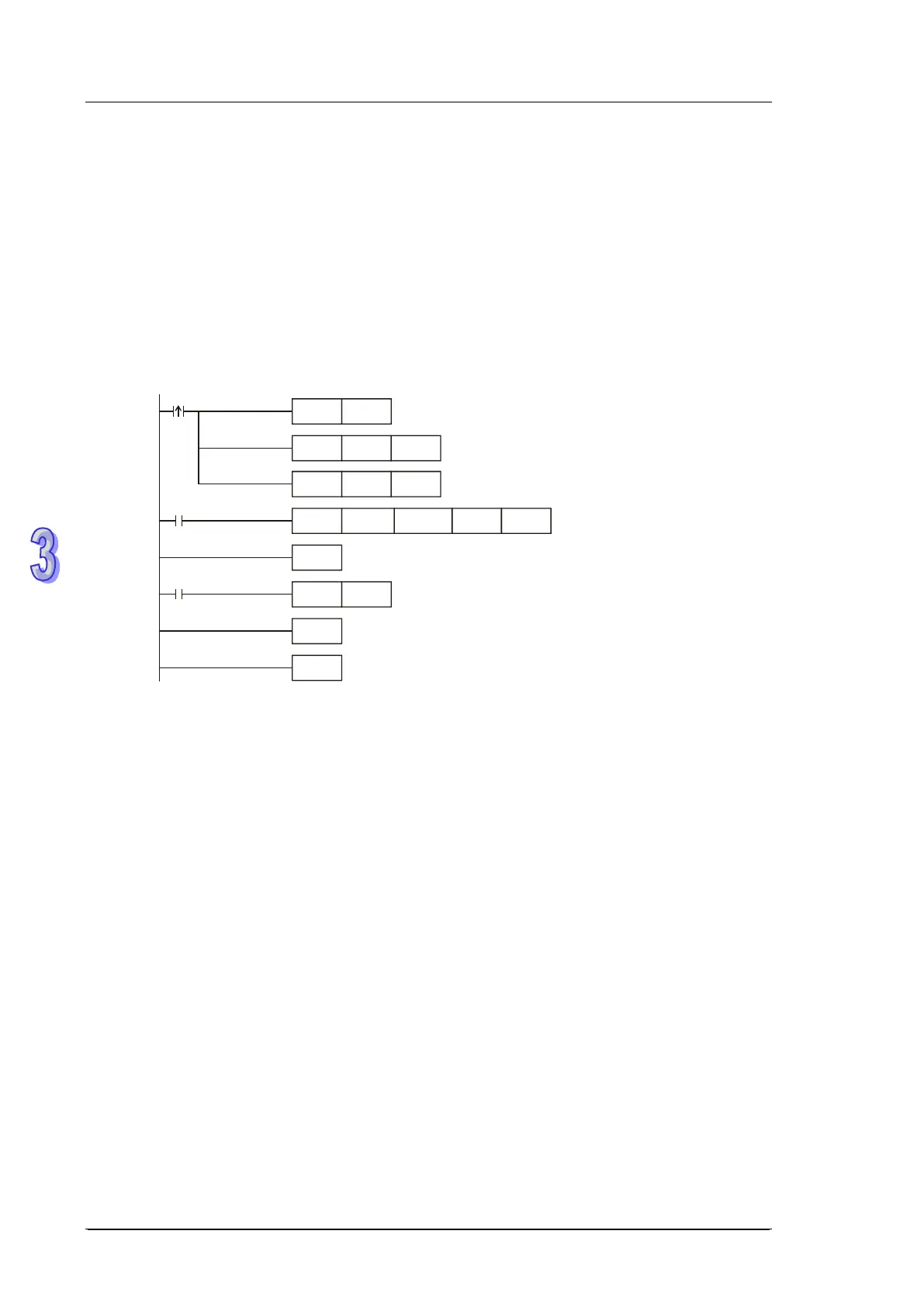

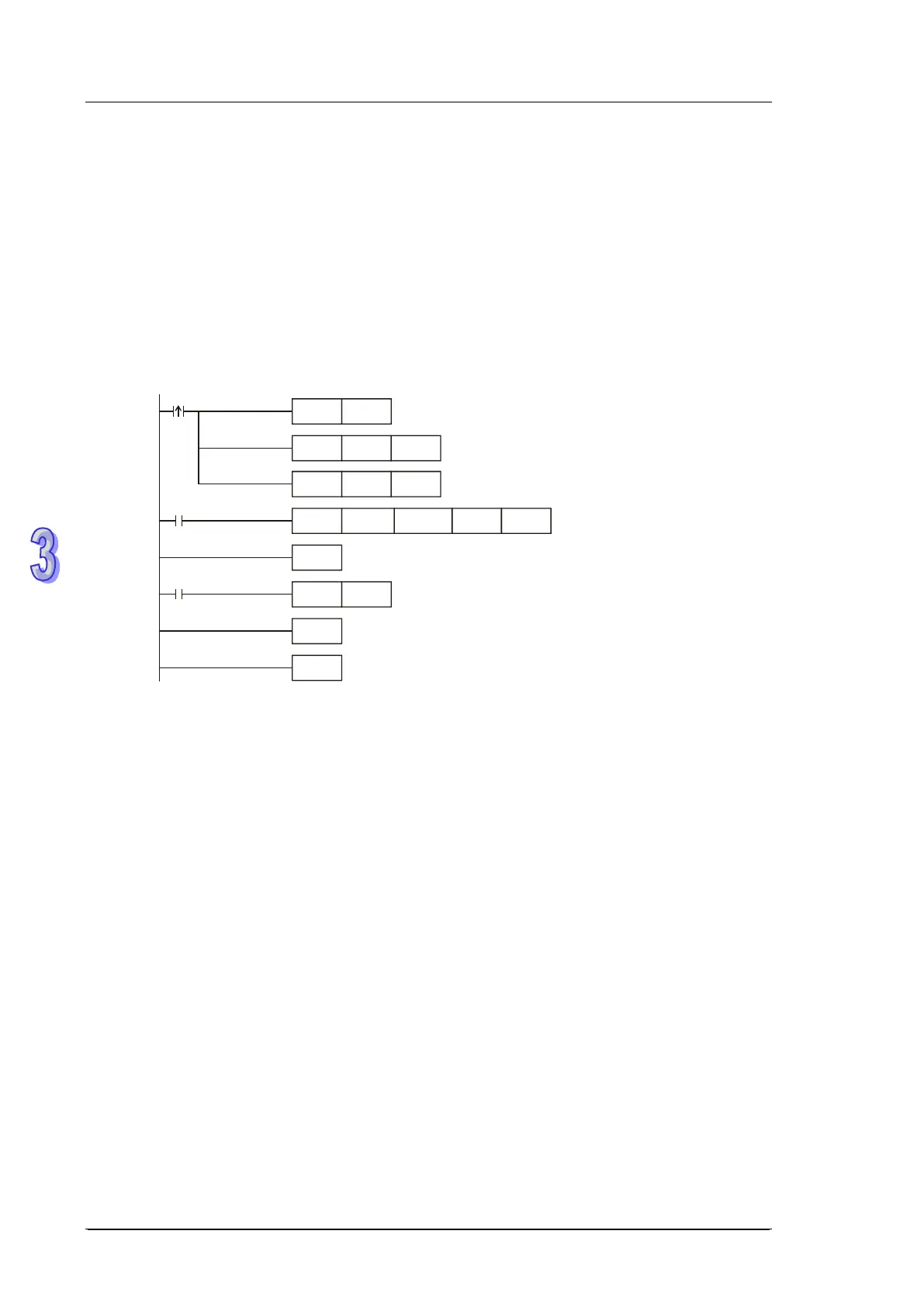

Program example 2:

M0

Y0

M0

M1000

I401

SET

M1156

DMOV

DPLSR

K100000

K1000000 K20

FEND

INCP

D0

IRET

END

DMOV

K10000 D1232

K50000

D1026

Explanations:

When M0 is triggered, Y0 executes pulse output. When external interrupt is detected on X4

after 50,000 pulses, pulse output will perform ramp down process for 10,000 pulses and

then stop. M1108 will be ON. If no interrupt is detected on X4, Y0 pulse output will stop after

1,000,000 pulses are completed.

Interrupt triggered between 0 ~ 50,000 pulses will be invalid, i.e. no ramp-down process will

be performed before 50,000 pulses are achieved.

Points to note:

When Mark function is executed with Mask function, PLC will check the validity of Mask

range first, then ramp-down stop pulses of Mark function. If the above set values exceed the

proper range, PLC will automatically modify the set values after the instruction is executed.

When PLSR or positioning instructions with ramp-up/down section are enabled, the user

can check the pulses of ramp-up section in DD1127 and pulses of ramp-down section in

DD1133.

Users can perform single speed positioning when ramp-up/down time setting is not

specified.

Loading...

Loading...