ASDA-A2 Chapter 5 Trial operation and Tuning

Revision February, 2017 5-9

5.5 Trial Run without Load (Position Mode)

Before the trial run without load, firmly secure the motor base so as to avoid the danger cause by

the reaction of motor operation.

Step 1:

Set the control mode of the servo drive to position mode.

Set parameter P1-01 to 1, which is the position mode. Then, re-power on the servo drive.

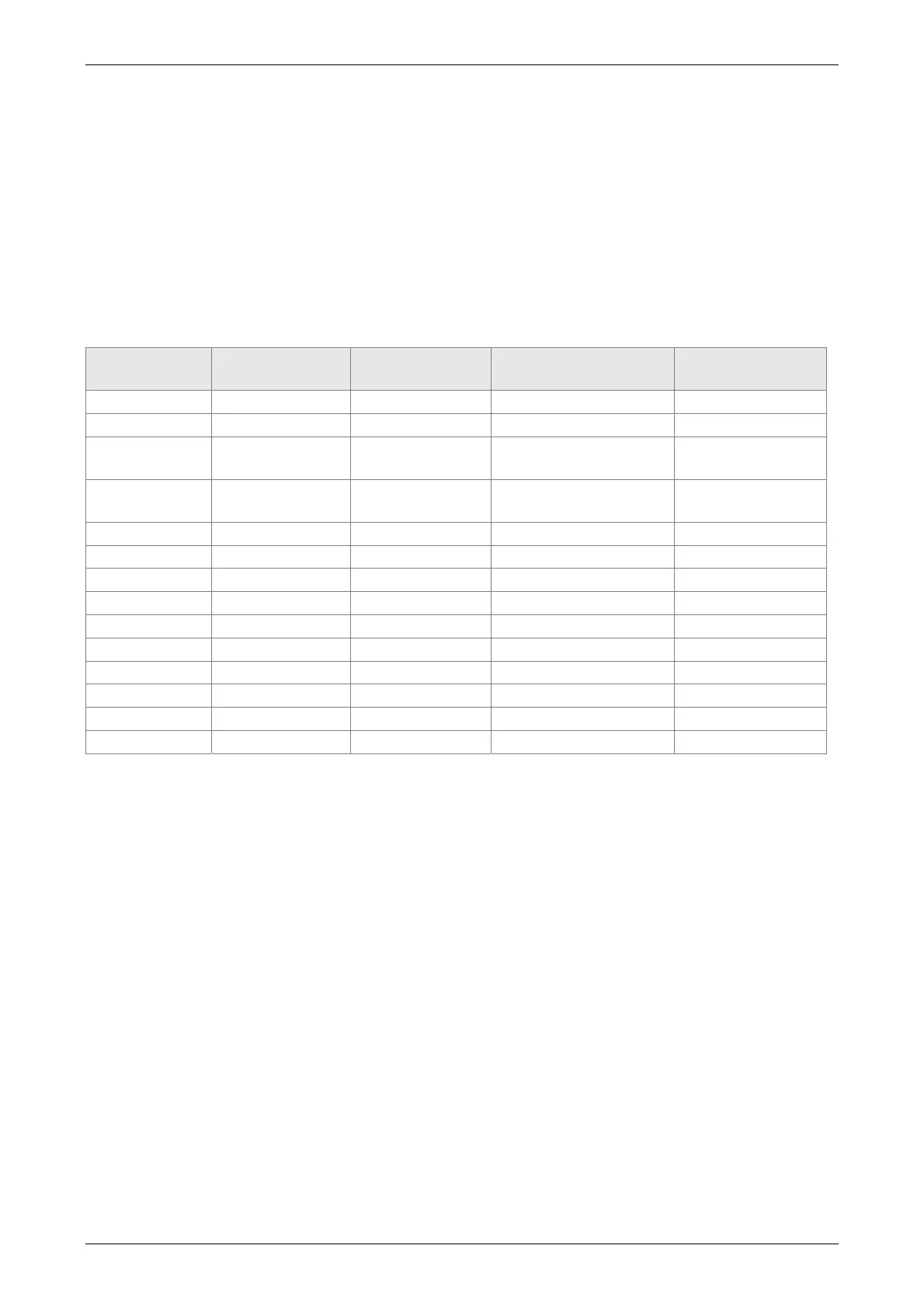

Step 2: In position mode, the digital input settings of trial run are as follows:

Digital Input

Parameter

Setting Value

Symbol Function Description CN1 Pin No

DI1 P2-10 = 101 SON Servo ON DI1- = 9

DI2 P2-11 = 108 CTRG Command triggered DI2- = 10

DI3 P2-12 = 111 POS0

Position command

selection

DI3- = 34

DI4 P2-13 = 112 POS1

Position command

selection

DI4- = 8

DI5 P2-14 = 102 ARST Alarm reset DI5- = 33

DI6 P2-15 = 0 Disabled Invalid DI function -

DI7 P2-16 = 0 Disabled Invalid DI function -

DI8 P2-17 = 0 Disabled Invalid DI function -

EDI9 P2-36 = 0 Disabled Invalid DI function CN7 = 2

EDI10 P2-37 = 0 Disabled Invalid DI function CN7 = 3

EDI11 P2-38 = 0 Disabled Invalid DI function CN7 = 4

EDI12 P2-39 = 0 Disabled Invalid DI function CN7 = 5

EDI13 P2-40 = 0 Disabled Invalid DI function CN7 = 6

EDI14 P2-41 = 0 Disabled Invalid DI function CN7 = 7

The above table disables the function of negative limit (DI6), positive limit (DI7) and emergency

stop (DI8), thus, set P2-15 ~ P2-17 and P2-36 ~ P2-41 to 0 (Disabled). The digital input of Delta’s

servo drive can be programmed by users. When programming digital input, please refer to the

description of DI code.

The default setting includes the function of negative limit, positive limit and emergency stop,

therefore, after the setting is completed, if there is any alarm occurs, please re-power on the servo

drive or switch ON DI5 to clear the alarm. Please refer to Chapter 5.2.

Please refer to Chapter 3.12.2, Position (PR) Mode Standard Wiring for wiring diagram. However,

since POS2 is not the default digital input, set P2-14 to 113. Please refer to the table below for 64

sets of register command, POS0~POS5 and the relative parameters.