ASDA-A2 Chapter 7 Motion Control

7-22 Revision February, 2017

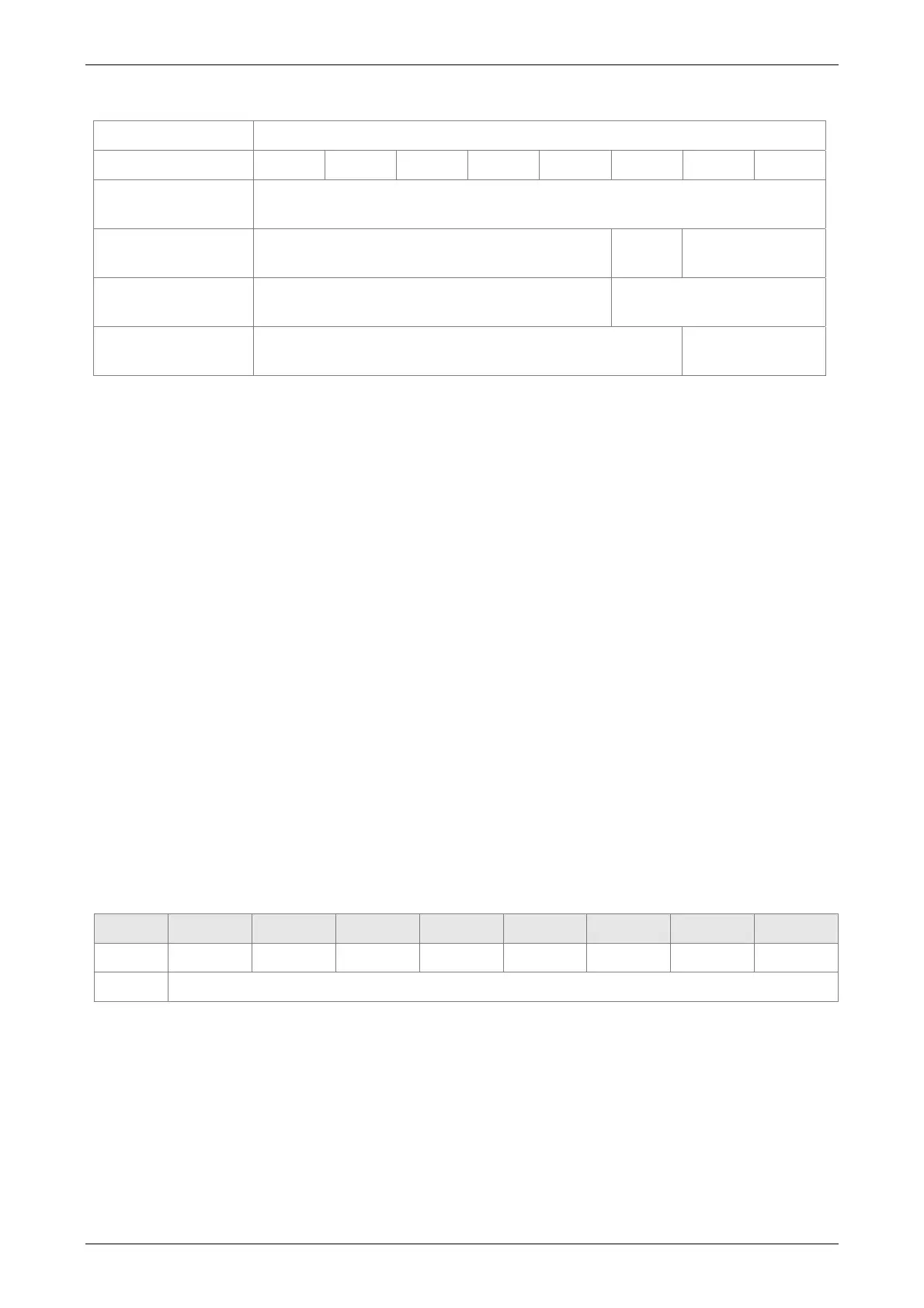

SOURCE: Settings of data source

SOURCE

Bit

31 ~ 28 27 ~ 24 23 ~ 20 19 ~ 16 15 ~ 12 11 ~ 8 7 ~ 4 3 ~ 0

SOUR = 00 means

constant

Para_Data

SOUR = 01 means

parameter Px-xx

Rsvd (0x0000 0) P_Grp P_Idx

SOUR = 10 means

data array

Rsvd (0x0000 0) Array_Addr

SOUR = 11 means

monitoring variable

Rsvd (0x0000 00) Sys_Var

P_Grp, P_Idx: specified parameter group and number

Array_Addr: specified the position of data array

Para_Data: the written constant

Sys_Var: monitor parameter code. Refer to P0-02 for its setting.

When Rsvd is not 0, it will display AL.213. When P_Grp exceeds the range, it will display AL.207.

When displaying AL.209, it means P_Idx exceeds the range.

When Array_Addr exceeds the range, it will display AL.213. And AL.231 is for Sys_Var exceeding

the range.

Note: 1. Even when the written parameter is retained, the new value will not be written into

EEPROM. Too frequent written will not shorten the lifetime of EEPROM.

Note: The aim of writing parameters via PR procedure is for turning ON/OFF or

adjusting some functions. (E.g. according to different positioning command to

adjust P2-00, Position Loop Gain.) This procedure will continuously repeat during

the operation. If the data is all written into EEPROM, it will shorten the lifetime of

EEPROM. In addition, if P2-30 is set to 5, the modified parameters (either from

panel or communication) will not be saved and is inconvenient to use. Thus, this

new function is added.

3. If writing parameters fails, alarm AL.213~219 will occur (Refer to Chapter 11 of the manual)

and the next PR which is enabled by AUTO function will not be executed.

10) Special Function: TYPE = 0xA, Indexing command.

Bit

31 ~ 28 27 ~ 24 23 ~ 20 19 ~ 16 15 ~ 12 11 ~ 8 7 ~ 4 3 ~ 0

DW0 - OPT2 DLY SPD DEC ACC OPT 0xA

DW1 DATA (32-bit): Indexing Coordinate Command, Unit: PUU