Troubleshooting / Dépannage

• We recommend that you use only genuine Delta

®

replacement parts.

• DO NOT USE EXCESSIVE FORCE to close the inlet stop stem. We RECOMMEND that the flushometer be flushed while closing the inlet stop. The noise

created by the water flow or the flow into the fixture will stop when the inlet water is shut off.

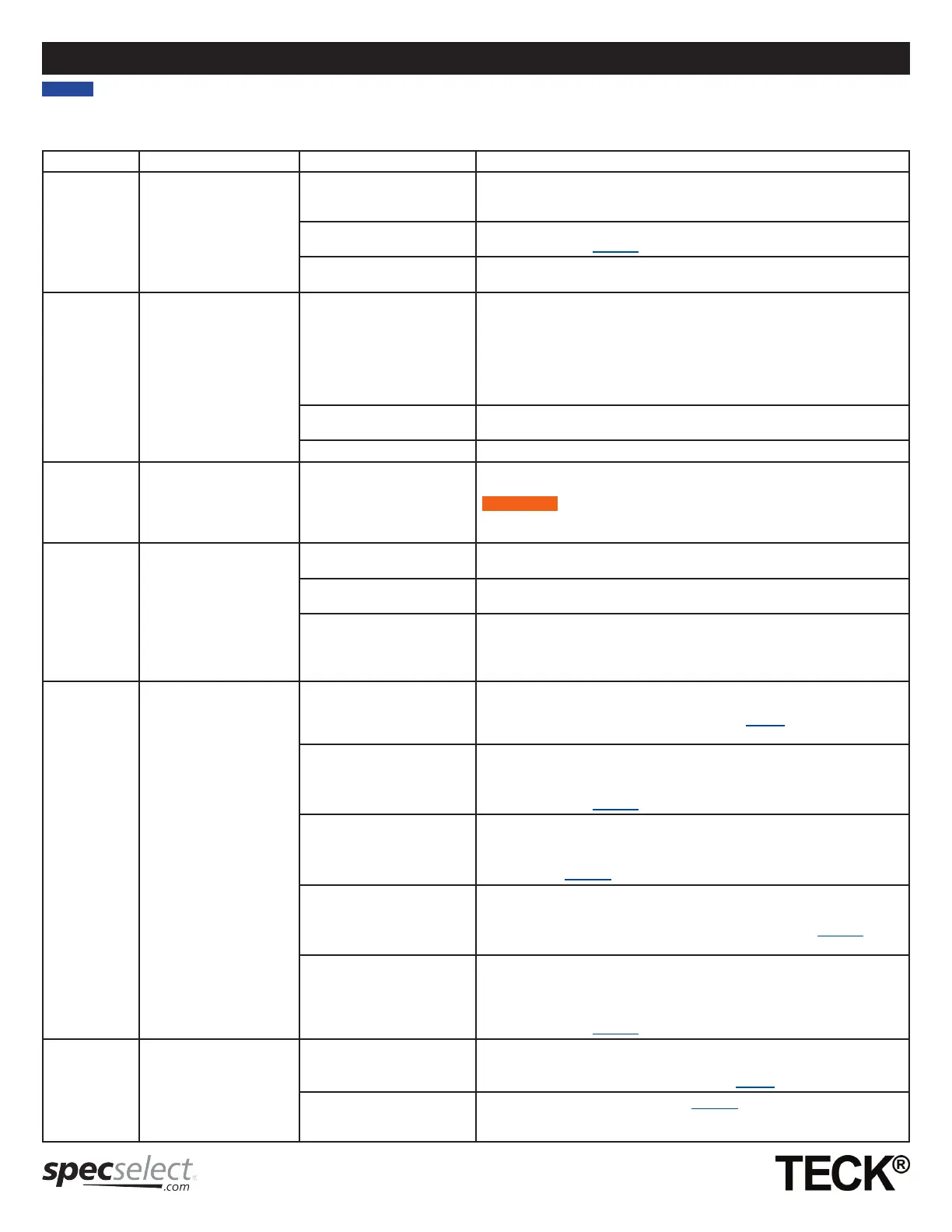

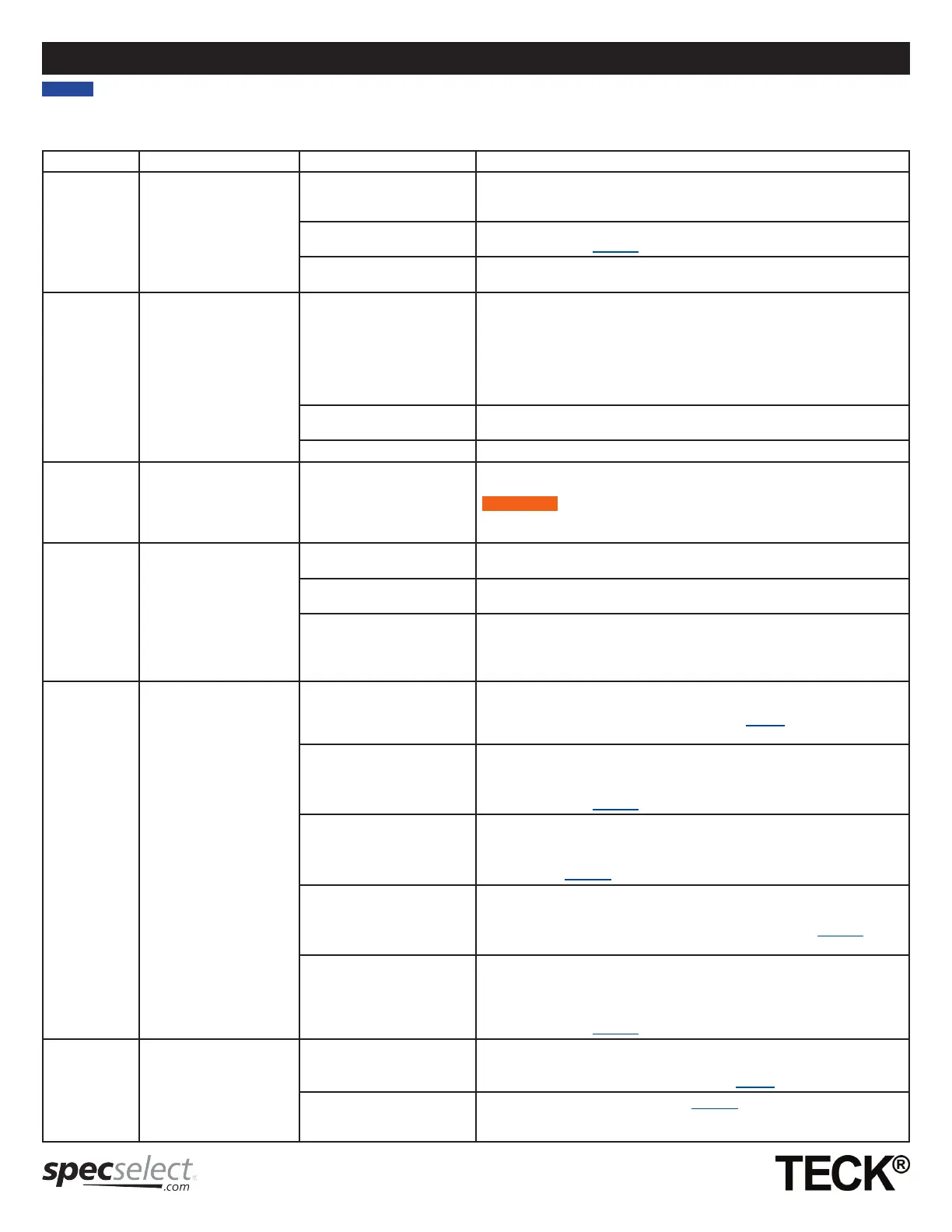

Problem Indicator Cause Solution

No lights on

sensor

No power Batteries not installed

correctly.

Check that the four “AA” Alkaline batteries are positioned properly in the

battery holder. Use the +/- signs on the batteries and the +/- signs on the

battery holder for correct positioning.

Batteries are depleted. Replace with four new “AA” Alkaline batteries (see “Battery Replacement

(see Figure 15)” on page 19).

Damage or corrosion of the

battery terminals.

Check for damage or corrosion of the battery terminals in the battery holder.

Replace battery holder and batteries if necessary.

Excessive

noise

Excessive noise High pressures may lead to

an increase in noise.

While the TECK Flushometer will operate up to 125 PSI, the preferred

operating range is between 35 to 65 PSI.

1. Lower the flow rate by reducing the flowing pressure upstream of the

flushometer by adjusting the screw stop. Close the stop completely and

re-open 1 turn. Then adjust the screw to stop the noise.

2. Other options include installing a Pressure Reducing Valve (PRV), or ball

valve upstream to the flushometer.

Damaged renewable seat. On flushometers that have been installed for a number of years, check the

renewable seat for wear and replace if necessary.

Partially closed inlet stop. Open inlet stop

Excessive

water flow rate

Splashing of water out of

the fixture.

Inlet stop may be open too

much.

Close the stop completely and re-open 1 turn. Adjust the stop to meet the

required flush volume specification.

W

Operation of flushometer with inlet stop BELOW ONE TURN

OPEN may cause EXCESSIVE NOISE. The lowest open setting for the

inlet stop may vary depending on the installation.

Shortage

of water to

properly flush

bowl

Fixture does not clear

waste.

Inlet stop may not be open

enough.

OPEN inlet stop fully.

Supply line may be blocked

or under sized.

CHECK supply line for size or obstruction, partially closed gate or other

supply line valve, corroded or under size water piping.

Not enough water pressure

and/or flow rate.

CHECK water pressure and flow rate.

Water supply may be restricted upstream. Open any devices being used to

restrict pressure and/or flow rate to the flushometer (PRV, ball valves, supply

stops).

Continuous

flushing

Flushometer does not stop

after cycle is complete.

The Regulating Screw may

require adjustment.

Adjust by slowly turning the regulating screw LEFT (counter-clockwise)

(except on models that have a fixed volume). See section “Flush Volume

Adjustment/Réglage Du Volume De Chasse” on page 7 for detail on

adjusting.

Bypass slot partially or

completely obstructed.

1. Clean bypass slot.

2. Replace cap/solenoid & regulating screw assembly if required.

See section “Cap/Solenoid & Regulating Screw Assembly Maintenance

(see Figure 18)” on page 21 for instructions.

Diaphragm/Guide Assembly

obstructed or damaged.

1. Check for damage and alignment of the diaphragm.

2. Replace Diaphragm/Guide Assembly if required.

See section “Diaphragm/Guide Assembly and Seat Maintenance (see

Figure 19)” on page 22 for instructions.

MMO button not working

correctly.

1. Clean MMO button assembly.

2. Replace MMO button assembly if required.

See section “MMO Button Maintenance (see Figure 20)” on page 23 for

instructions.

Solenoid not connected to

controller or damaged.

1. Verify wiring is connected correctly.

The solenoid is connected black to

black, red to red with the

electronic compartment

.

2. Replace cap/solenoid & regulating screw assembly if required.

See section “Cap/Solenoid & Regulating Screw Assembly Maintenance

(see Figure 18)” on page 21 for instructions.

Inadvertent

flushing

Flushometer will activate

with no one using the

fixture.

Sensor range needs to be

adjusted.

Verify sensing range of the flushometer and adjust if required.

See section “Setup Mode Adjustments (see Figures 10-11) / Réglages du

mode d’installation (voir la Figures 10-11)” on page 8 for instructions.

Sensor requires adjustment

for reflection of infrared

signal.

See section “Inadvertent Flushing” on page 20 for instruction on sensor

angle adjustment.

Page - 15 of 25

213631, Rev. A

Loading...

Loading...